HCI: How to Rewind an Ellipse Shaped Product - Dare to Try Automated Process Solutions - Ellipse Shaped Reel Rewinder

A reputed professional filter manufacturer in Taiwan contacted HCI. They specialize in the production of corrugated axial air filters, and have obtained many patents in Taiwan, China, Japan, Germany and the USA. However, it encountered great difficulties in the rewinding process, because the finish product is an ellipse shaped reel. That's right, it is an [ellipse] rather than a round product that we are familiar with. At present, customers can only rely on manual equipment for several stages of production. Not only the production capacity is low, and not able to improve the yield rate.

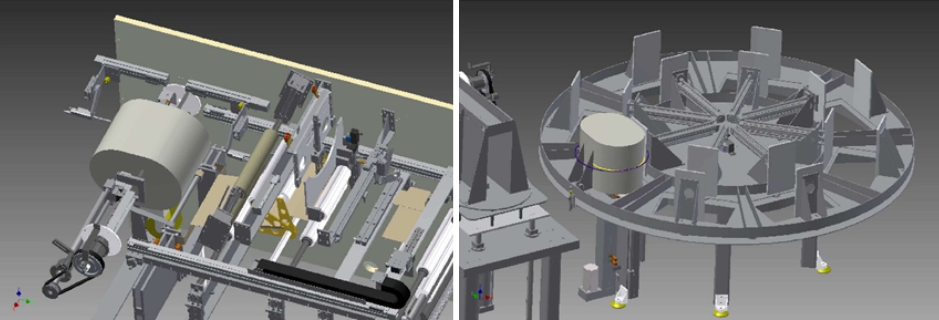

In the past, all rewinding reels were round shape, the operation speed and tension can be accurately controlled through the calculation based on the circumference and diameter. The revolution here is, the roll diameter at each angle is different, and it also changes with the increase of the roll diameter. This is really a new challenge that has never been thought of.

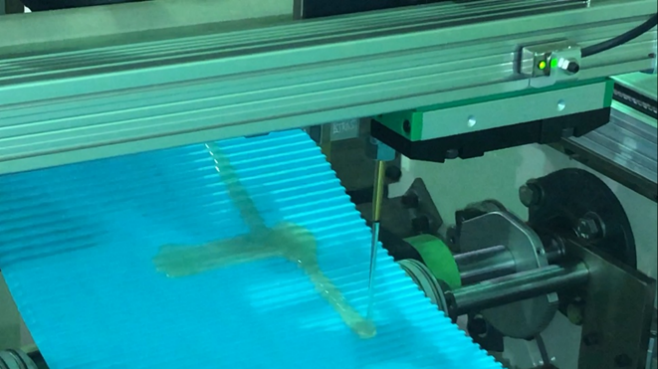

PLC precisely controls the gluing path.

The product is the air filter for car engine or air compressor. Operating procedure requirements are to apply hotmelt glue at specific psth, and then rewind it into an elliptical shape reel. Not only that it needs to be automatically cut when the pre-set length reached and also the tail must stop at a specific position of the finished product. After that the products need to be picked up by a robot and have it fixed on the curing turntable; at the same time, the machine has to deliver the material and fix it on the winding table to continue the operation automatically. In short, it is to integrate the manual process that is currently divided into several stages into one and have automation non-stop production.

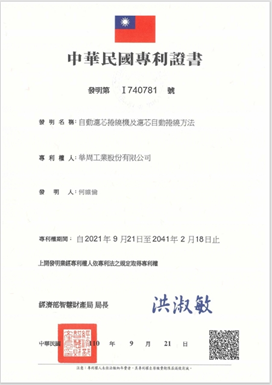

After a huge discussion by HCI technical team, we decided to accept this "Mission Impossible" challenge. Based on more than 40 years technical experience, we always uphold that if you need it, we will do it! HCI technical team integrates the technology of products length, diameter and tension control from rewinding machine, glue application from shrink sleeve seaming machine, forming mechanism, dancer roller and cutting length control from pouch making machine plus countless meetings, discussions and trial adjustments. Finally, we did it and got the invention patent! The customer has also successfully obtained orders from major automobile manufacturers due to the increase in production capacity and yield rate.

HCI is always with customers to provide the most practical solutions for flexible packaging technology. Realize the blue ocean strategy of creating a win-win situation with customers again.

Within his work experience he has been involved in the strategic planning and launching in new products, also working close with customers for better understanding of their needs and also responsible of marketing strategies, branding and image of the company.