New Milestone of GMA—HASTELLOY Processing & Application

HASTELLOY® C276 (UNS N10276, hereinafter referred to as C276) is one of alloy to be well against high corrosive chemical, such as Chloride gas、Hypochlorite、Chlorine dioxide, special to Oxidizing salt solution (such like Ferric Chloride and Copper chloride), C276 is with excellent tolerance, currently, C276 is recognized as the best alloy for anti-corrosion metal.

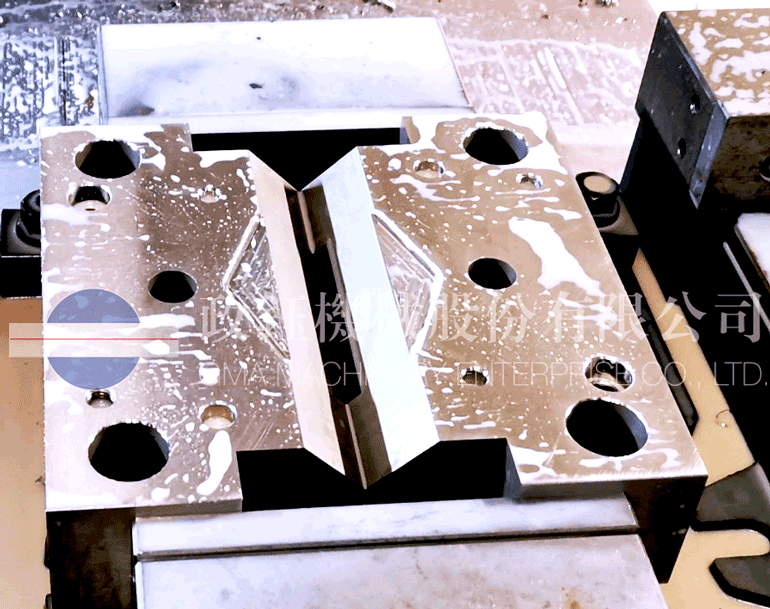

C276 is called “devil metal”, due to high difficulty of processing C276. Compared with other alloy, when cutting tool works on C276, it causes high heat, leads to cutting heat hardening of C276 quickly in processing. Such processing way make cutting tool be broken easily, meanwhile, short at least 30% lifetime of cutting tool, reduce processing efficiency around 50% to 60%, the most difficult point is to reach well precision machining.

GMA customers are in various industries, for meeting market demand, more and more customers are looking for C276, most of them come from Chemical and electronics industry, simultaneously, they are looking for good manufacturer who has enough ability to process C276 well. Few years ago, GMA saw the trend and started to improve processing, at the same time, we tried to find the best solution of processing C276.

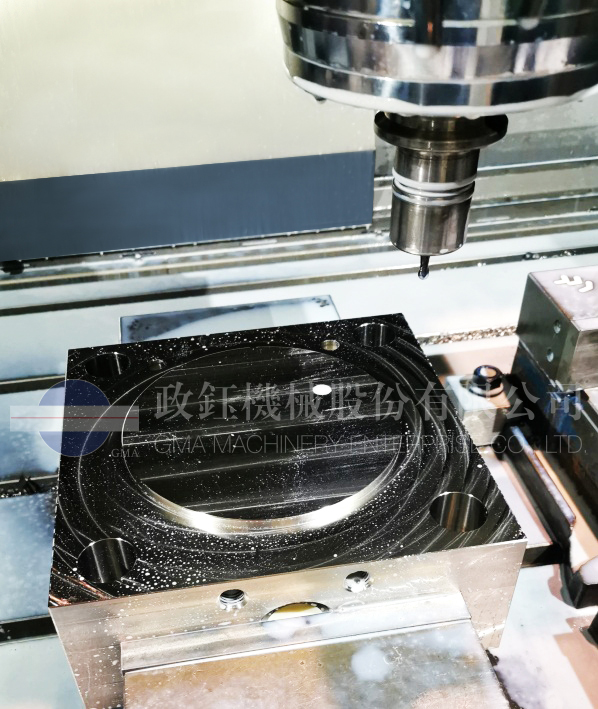

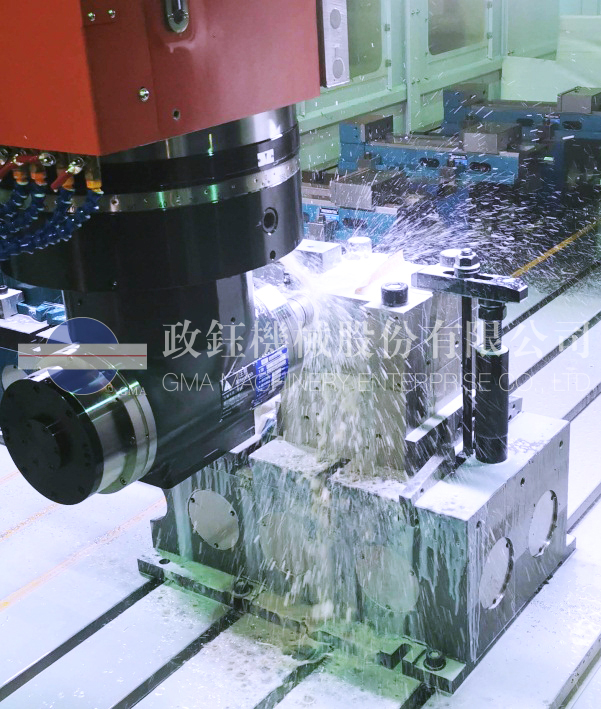

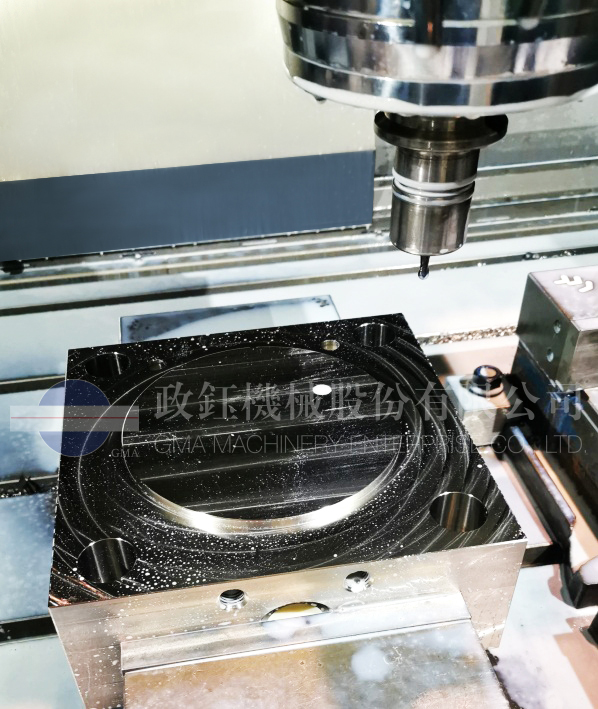

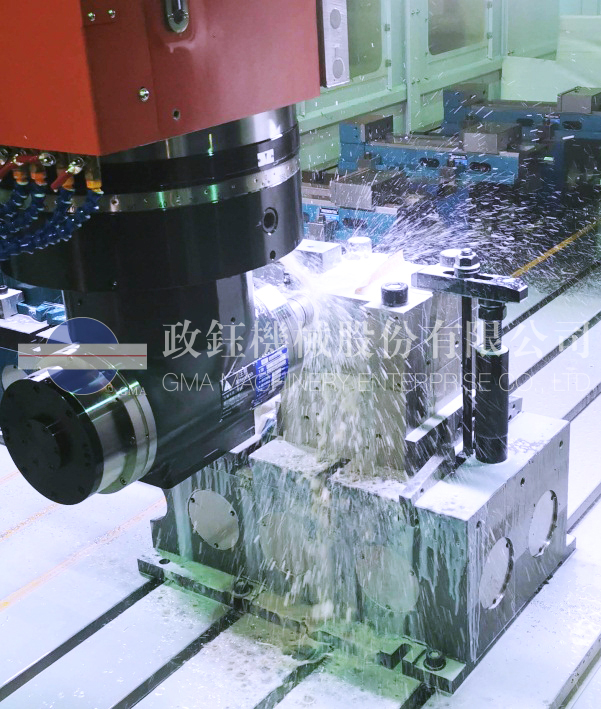

GMA team tried different processing condition with high performance machine center, including the material and coating of cutting tool、cutting oil concentration、temperature for cutting、cutting speed etc., taking low temperature and keeping cutting speed around 15~45M /min, after milling、lathing and drilling processing etc.

after many times trial, we find out the solution for processing C276.

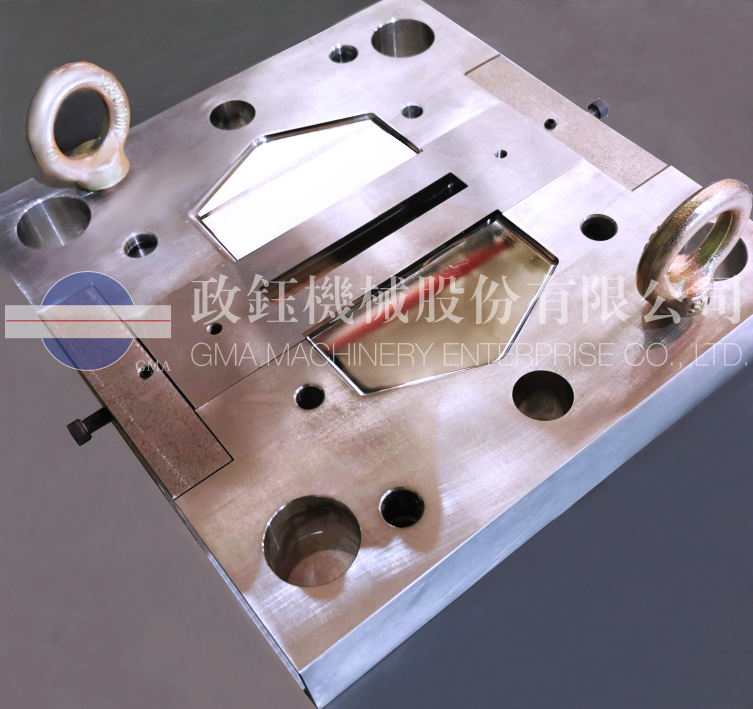

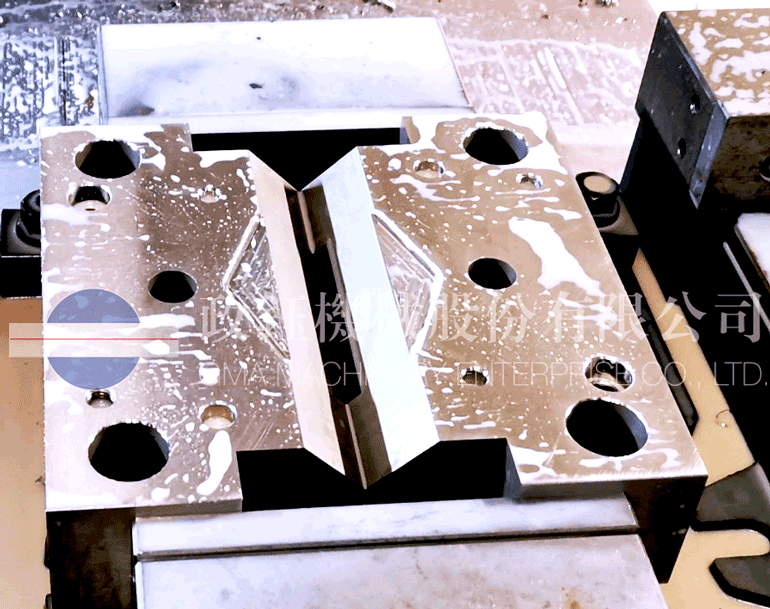

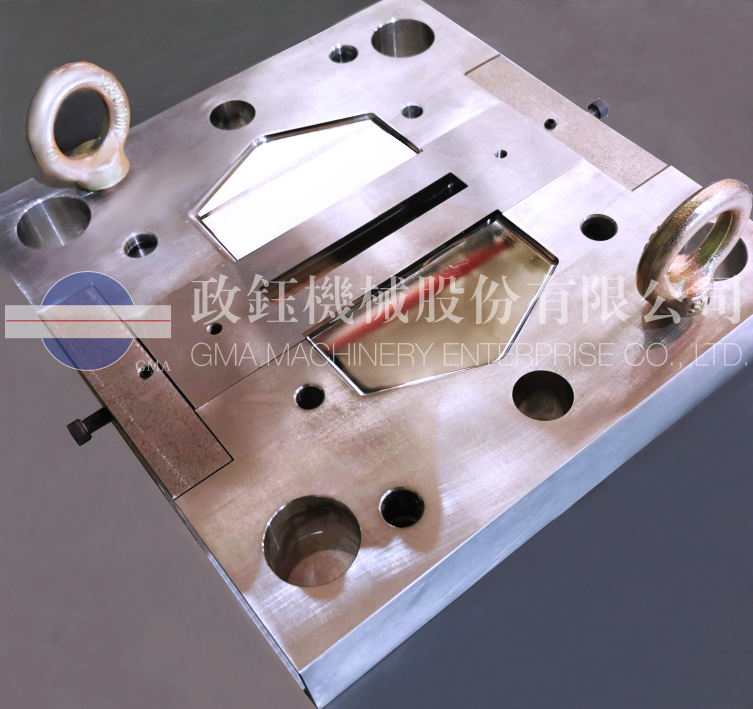

The most difficult processing point of C276 is drilling, but in GMA standard processing, for making different shape channel or very deep hole, such as the L/D ratio is usually over 12 times, we have to use many drilling skills, the above factors make processing C276 much harder. GMA team gave up traditional processing way, refer processing way of aerospace application, to take the core skill to apply on C276 processing, to reach precision processing grade .

GMA team overcomes many key points , processing C276 becomes our own unique technology, at the same time, we successful get orders from Japan and Europe, for GMA, the achievement of C276 processing is absolutely a new milestone.

C276 is called “devil metal”, due to high difficulty of processing C276. Compared with other alloy, when cutting tool works on C276, it causes high heat, leads to cutting heat hardening of C276 quickly in processing. Such processing way make cutting tool be broken easily, meanwhile, short at least 30% lifetime of cutting tool, reduce processing efficiency around 50% to 60%, the most difficult point is to reach well precision machining.

GMA customers are in various industries, for meeting market demand, more and more customers are looking for C276, most of them come from Chemical and electronics industry, simultaneously, they are looking for good manufacturer who has enough ability to process C276 well. Few years ago, GMA saw the trend and started to improve processing, at the same time, we tried to find the best solution of processing C276.

GMA team tried different processing condition with high performance machine center, including the material and coating of cutting tool、cutting oil concentration、temperature for cutting、cutting speed etc., taking low temperature and keeping cutting speed around 15~45M /min, after milling、lathing and drilling processing etc.

after many times trial, we find out the solution for processing C276.

The most difficult processing point of C276 is drilling, but in GMA standard processing, for making different shape channel or very deep hole, such as the L/D ratio is usually over 12 times, we have to use many drilling skills, the above factors make processing C276 much harder. GMA team gave up traditional processing way, refer processing way of aerospace application, to take the core skill to apply on C276 processing, to reach precision processing grade .

GMA team overcomes many key points , processing C276 becomes our own unique technology, at the same time, we successful get orders from Japan and Europe, for GMA, the achievement of C276 processing is absolutely a new milestone.

Author:GMA MACHINERY ENTERPRISE CO., LTD.

Founded in 1989, the GMA Machinery Enterprise Co., Ltd. (GMA), an R&D team composed of senior design engineers and technicians with decade’s strong experience in sheet and film extrusion equipment and auxiliary parts, has been devoted to providing custom products based on customer requirements. With 30 years of continuous efforts, it is the leaders in Taiwan’s extrusion die industry.