回收機械及設備

熱門訊息

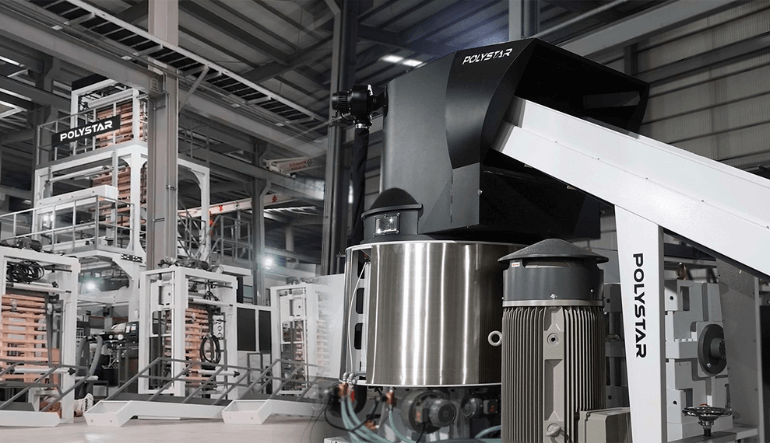

POLYSTAR Co-extrusion & Recycling: Making Plastic Film Sustainable

With the increasing concern over plastic waste and pollution, plastic bag manufacturers are looking for more sustainable production methods to diminish the negative effects of their plastic products. Co-extrusion and recycling are two techniques that are gaining popularity in the plastic film industry. In this blog, we will explore how co-extrusion and recycling can create a circular economy for plastic bag production and minimize waste.

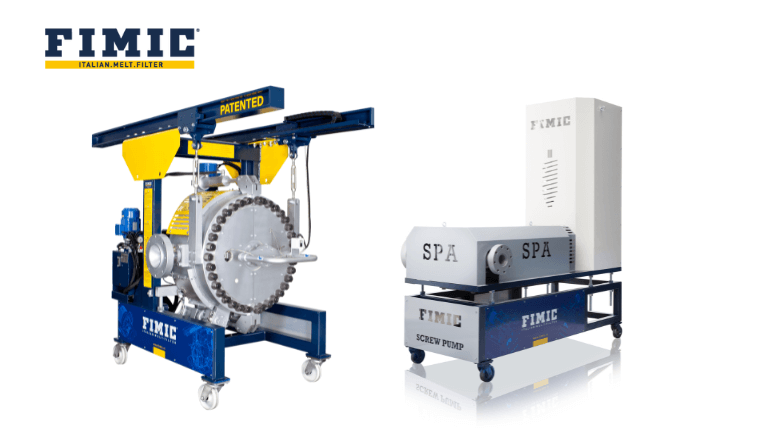

FIMIC Innovations in Automatic Filtration

Recycling is a game where size matters. Nowadays recyclers need to reach a higher hourly production capacity with efficiency and simplicity, they required right applications for high-throughput recycling lines. FIMIC has been working many years now on improving its filtration technologies in order to meet and satisfy the needs (quality, characteristics) of recyclers, and at the same time facing the challenges of recycling post-consumer and post-industrial plastics.

Plastic Recycling Hero Behind the Scenes, Geording Machinery Becomes a Trusted Manufacturer with Customization Capabilities

Plastic waste recycling has long been a symbol of green sustainability. With the rapid advancement of recycling technologies, applications have become increasingly diverse and abundant. The World Economic Forum predicts that by 2030, the global circular economy will reach $4.5 trillion. Internationally, there are new applications emerging, such as environmentally friendly building materials made from PET bottle bricks and eyeglass materials made from discarded fishing nets. Coca-Cola Taiwan has also invested significant research and development efforts, spending seven years to develop products using 100% recycled plastic bottles, setting a new milestone in plastic recycling applications.

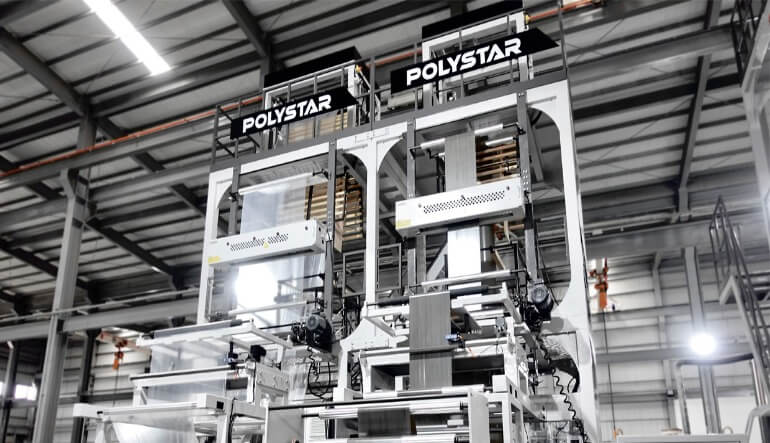

Flexible POLYSTAR Blown Film Extruders for Sustainable Packaging

Eco-friendly packaging is a necessity more than a trend, for both environmental and economic sustainability today. As one of the main carriers of packaging film production, blown film extrusion technology must keep evolving to meet the market requirements. Let's take a closer look into how POLYSTAR develops its blown film extrusion machine technology to better contribute to eco-friendly packaging.

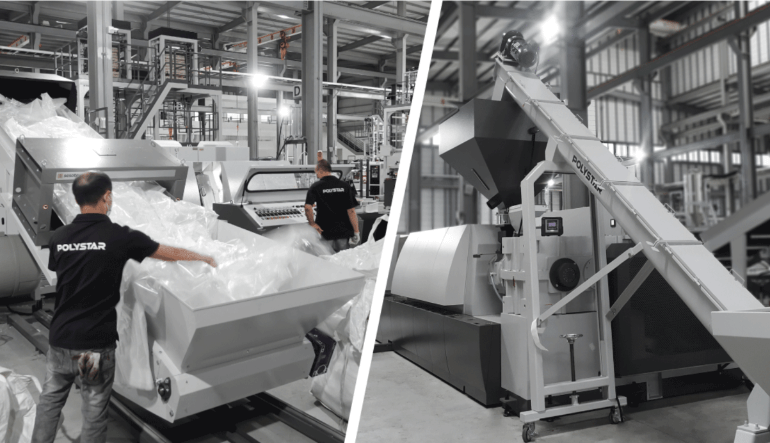

Daisaku Co., Ltd. and POLYSTAR Collaborate to Lead Japan's Plastic Waste Recycling Industry

DAISAKU CO., LTD, located in Ibaraki Prefecture, Japan, is a leading enterprise in the plastic waste recycling industry. We have been collaborating with POLYSTAR since 2019 to enhance our plastic recycling business. Our partnership with POLYSTAR includes the purchase of their Repro-Flex 150 recycling machine to process various HDPE/LDPE/LLDPE packaging film/bale film/shrink film waste.

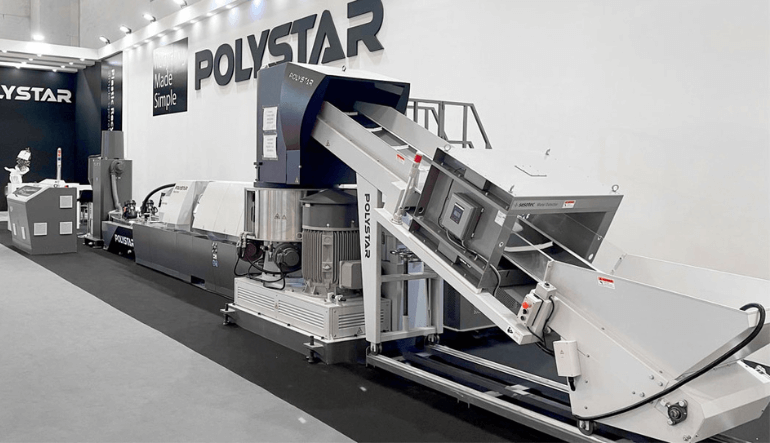

POLYSTAR Pelletizers for Soft and Rigid Plastic Wastes - Which Granulating System Can Fit Your Demands Best?

Different plastic materials have their unique properties and are manufactured into many categories of products such as plastic films, food packaging, flexible plastic packaging, medical device components, etc. While recycling the plastic waste from particular materials, the plastic pelletizers chosen must be capable of processing your main waste stream, as well as flexible enough to process your side plastic waste.

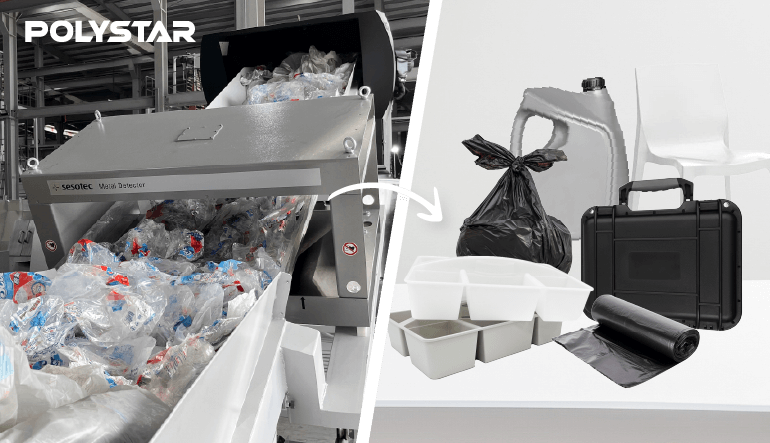

Recycling Materials with POLYSTAR for New End Product Possibilities

With consumers increasingly pushing for less raw material usage, the last few years have exhibited an increase in recycled plastics as basic materials for production, helping repurpose products that otherwise would be considered waste. But what type of plastic materials can be recycled? How can plastics be recycled? And what end products can be made using recycled materials?

POLYSTAR's Exponential Growth in Türkiye Fueled by Delighted Customers!

Post-industrial and post-consumer plastic recycling activities are rapidly growing in Türkiye and contribute to environmental as well as economic sustainability. POLYSTAR is proud of standing with Turkish plastic recyclers and manufacturers by providing simple-to-use yet efficient plastic recycling machines. Today, over 45 POLYSTAR machines operate in Türkiye.