Implementing Sustainable Circularity: PIDC Creates Low-carbon New Packaging Materials

Under the pressure of climate change and global warming, low-carbon, zero-net emissions, and sustainability have become global consensus and important proactive measures. Advanced countries such as the European Union and the United States have successively announced policies and regulations on the restriction and recycling of single-use plastic products and achieving net-zero carbon emissions. For example, the European Union and the United States directly require that all packaging materials must contain 25% recycled content by the end of 2025. In addition, plastic and rubber manufacturers are constantly exploring low-carbon sustainable materials with high value potential and developing plastic recycling and regeneration to create a complete green economic industry chain from upstream to downstream.

Amidst the wave of low-carbon sustainable development, the Plastics Industry Development Center (referred to as the Plastics Center), a foundation dedicated to plastic industry technology development, organizes an annual plastic industry innovation forum. During the event, representative companies from the industry also present the production of a new generation of packaging products using polypropylene (PP) clarifiers. This innovative plastic packaging material can save 15% in processing temperature and achieve a 10% energy-saving effect in low-carbon processes. By reducing processing temperature and electricity consumption, it can significantly reduce CO2 emissions. It represents a new generation of low-carbon and energy-efficient plastic packaging products, contributing to the protection of the Earth's environment, resources, and sustainable cycles.

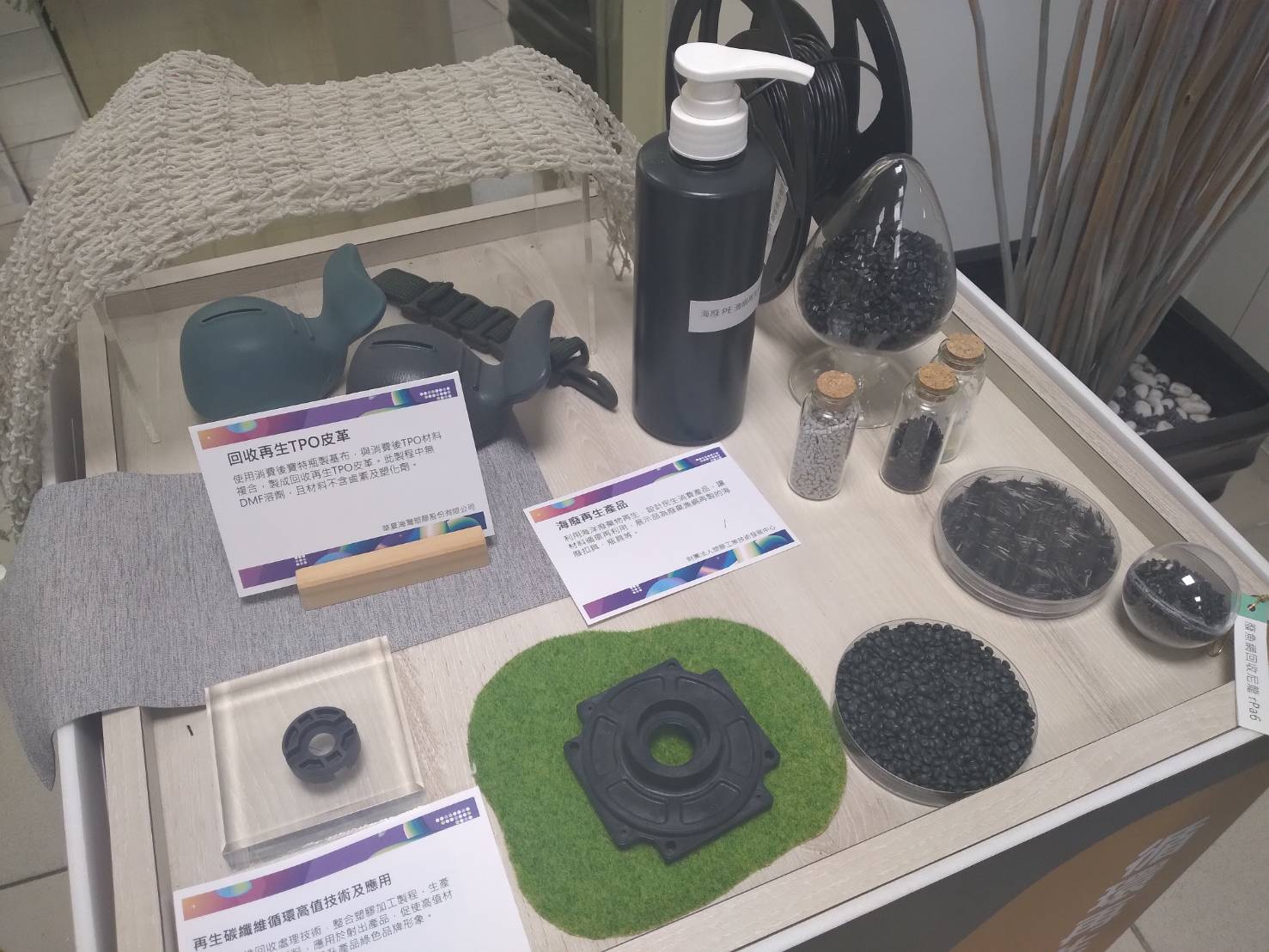

Image: Creating a new generation of circular recycled products.

Under the wave of the circular economy, various brands and manufacturers are also seeking relevant strategies to promote recycling, reuse, and repurposing of products, aiming to achieve a green circular economy. The Plastics Industry Development Center (Plastics Center) uses creativity and ingenuity to assist businesses in transforming post-consumer products or waste into other recycled products. For example, the center has successfully helped businesses develop consumer products such as sports eyewear, sportswear, laptop bags, and phone cases by recycling discarded fishing nets from the ocean through processes like cleaning, melting, and manufacturing.

Taiwan has achieved a high recycling rate of over 95% for PET bottles (rPET) through years of government promotion and efforts, leading globally in this aspect. The Plastics Center has a high level of expertise in rPET-related regulations and can assess the development and verification of energy for rPET in response to international trends. With a professional team, they can assist businesses in evaluation, verification, and obtaining suitability certification for PET recycled polyester materials for use in food containers and packaging from the Taiwan Food and Drug Administration, Ministry of Health and Welfare. They continue to provide businesses with high-quality packaging materials, contributing to the realization of a plastic circular green economy.