RE-PLAST EXTRUDER CORP. IPF JAPAN 2023 FAIR DEMO MACHINE: RTU

Going beyone the traditional fixed type designs, effectively achieving noise reduction and dust prevention.

Production speed up to 250 pcs/minute 15,000 pcs/hour.

Paper Bubble Mailer Making Machine, MGA-47P-1000

Learn More:https://www.mingjilee.com/tw/product/...

MING JILEE: PP Extrusion Line and Bag Converting Machine Since 1987

Made In Taiwan, Best Quality and Global Support

Website: https://www.mingjilee.com/

E-mail: [email protected]

Whatsapp: +886 934 081 955

Complete Address: No.76-8, Ming-Ho, Ming-Ho Vil., Shan-Shang Dist., Tainan City, 74342, Taiwan

ISOTHANE Bio TPU

Sustainable bioplastics derived from natural plants, Make life more energy efficient and make the world a better place to live.

特點

有別於傳統的料斗乾燥機,結晶式料斗乾燥機內部附加一支攪拌器,特製的葉片設計與一體成型的不銹鋼保溫筒身,在乾燥機運作時,同時地攪拌筒內的塑膠,亦可增加I.V.值。

配合晏邦專利設計的乾燥方法與保溫處理,不僅使塑膠乾燥均勻而且加快塑膠乾燥的速度,節省能源。更是PET 使用者不可或缺的最佳工具。

1.節省能源

乾燥時攪拌塑膠,配合專利設計的乾燥方式可使塑膠乾燥均勻、加快塑膠乾燥速度,節省能源。

2.防止架橋

塑膠因黏性強、含水(油)率高、形狀不一、新舊料混合產生架橋,縮短乾燥時間、有效降低不良率。

3.樣式多款

晏邦提供多款不同功用的攪拌器,無論結晶塑膠、防止架橋或乾燥均勻,皆能符合您不同的需求。

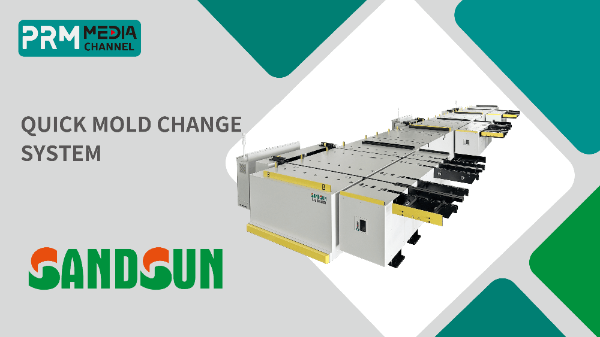

Learn more about the Quick Mold Change Systems : https://bit.ly/37ST04V

Sistema de cambio rápido de moldes, быстрый mold изменение системы, السريع تغيير النظام العفن produced by SANDSUN

Introduction of our Quick Mold Change System :

It is an era for making high frequency mold changes with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to apply Quick Mold Change System.

Sandsun safety function of Quick Mold Change System :

✔️Each hydraulic circuit has the function of checking and avoiding oil leaking.

✔️This system can add pressure automatically when the pressure reduction.

✔️Each hydraulic circuit has the function of inspection pressure and can be interlocked with the machine.

✔️It adopts the intersecting direction to clamp the mold.

✔️There are several functions to avoid operation error.

Explanation of video content :

Mold Change less than 2 minutes on 1300T injection molding machine

0:00 Quick mold change less than 2 minutes on injection machine

0:19 Pre-load the mold on the cart

0:23 Mold move out

0:36 Mold arrive in the position, and the cart start to switch position

0:49 Mold cart arrive in position

0:55 Injection machine adjust the stroke for mold automatically

1:04 Mold move in

1:21 Hook back to original point, door close automatically

1:28 Mold close, clamps lock the mold automatically

1:39 Protection rods rise, cart start to move

1:49 Cart back to mold hanging area, finish mold change

#PlasticReuse #MachineManufacturer #PlasticRecyclingMachine

00:00 Opening

00:08 Blown Film

00:28 Machine current speed

00:37 Cutting, Sealing & Punching

00:54 Sending finished bag to Carton Packaging Section

01:07 Take-up Tower & Printing

02:27 Carton Packaging Proccess

05:04 Ending

---

Website : www.jandis.com.tw & www.inflationmachine.com

Facebook : www.facebook.com/JANDIS.JIT

Email : [email protected]

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

SING SIANG MACHINERY CO., LTD

The machine is applied for solvent-based ink and direct printing method for woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value. Newly developed printing machine offers max. line speed 250M/Min and “New Type” Auto. Roller Exchanging System for Un-winder & Re-winder.

The medical tubes produced by Everplast's medical tube extrusion machines have excellent quality and accuracy. They use advanced manufacturing technology and precision machining processes to ensure that each medical tube has accurate dimensions and uniform texture, complying with the strict standards and standards of the medical industry. specification. Whether used for infusion, drainage, or other medical applications, these tubings provide reliable performance and safety. Meets the strict quality and specification requirements of the medical industry.

*Contact Info:

Web: https://www.everplast.com.tw/

Facebook: https://reurl.cc/r1LZb

YouTube:https://www.youtube.com/channel/UC_ziI3cDyRGjV71s8YkV-pg

1.https://www.everplast.com.tw/product/machine-line/medical-tube-machine-line/

2.https://www.everplast.com.tw/product/machine-line/

3.https://reurl.cc/QeMrp0

Tel: +886-2-2289-7271 / +886-6-201-4846

Fax: +886-2-2289-7282 / +886-6-201-4290

Email: [email protected]