Can’t find what you are looking for?

Fill in the inquiry form below, let us know about your requirements.

Our specialists will forward your inquiry to the related suppliers accurately.

Stay tuned, check your email box for notifications about your inquiry status.

Sign up for free, track your inquiries, contact your favourite suppliers directly.

注意事項

• 想要尋找機械或零件的供應商,請填寫以下資訊,選擇分類,向相關的供應商發送詢問函。

• 合作、媒體交換或任何非機械方面的諮詢,請通過電子郵件與我們聯繫。

• 合作、媒體交換或任何非機械方面的諮詢,請通過電子郵件與我們聯繫。

大分類

中分類

小分類

請勾選你想詢問的產品分類,確認完畢請按右上關閉

輔助設備 & 整合自動化設備

控制設備,

切割機,

表面處理機...

中空成型機

全自動中空成型機,

押出中空成型機,

射出中空成型機...

押出機與押出整廠設備

吹膜押出機,

管材及異型材押出生產線,

薄膜和片材生產線...

成品及半成品/OEM/ODM

聚酯短纖維,

薄膜,

夾鏈條...

射出成型機

全自動射出機,

臥式射出成型機,

立式射出成型機...

模具及模頭

押出模頭,

射出模具,

真空成型模具...

包裝機械

旋蓋機,

封口機,

套標機...

零組件

齒輪箱,

幫浦,

螺桿與料管...

塑膠後段加工機械

製袋機的應用,

工業針織機,

分切機和複捲機...

回收機械及造粒設備

造粒機,

製粒機,

廢塑料再生機...

印刷機

膠板印刷機,

水轉印機,

凹版印刷機...

原料及添加物

HDPE樹脂,

PA樹脂/尼龍,

TPE...

橡膠加工機械

壓縮成型機,

捏合機,

矽膠射出成型機...

製鞋機

旋轉式塑膠鞋類射出成型機,

製鞋機,

運動鞋製造機...

熱成型機

發泡成型機,

壓力成型機,

真空成型機...

全球電子報

Driving a Sustainable Printing Future through Customization: Printplas Meets Evolving Global Industry Needs

Taiwan-based Printplas Machinery Co., Ltd. delivers tailor-made flexographic printing solutions for packaging applications worldwide. With over 20 years of experience, Printplas provides CI and STACK-type presses optimized for diverse substrates and regional demands. From a 2700mm ultra-wide press in Russia to high-speed solutions across Latin America and Europe, Printplas exemplifies Taiwan’s strength in precision customization.

From Mold to Marvel: How Jia Thai Delivers Beauty and Precision, One Injection at a Time

When it comes to injection mold manufacturing, there are plenty of options. But few combine technical precision, aesthetic finesse, and decades of experience quite like Jia Thai Industrial Co., Ltd. Founded in 1990 in Taiwan, Jia Thai has quietly built a reputation over the past 30+ years as a reliable partner for high-end mold solutions—especially in the cosmetic and automotive sectors.

Bagging the Global Market: How COSMO Machinery Earns International Trust Through Technology and Service

COSMO Machinery has carved out a significant position in the global bag-making equipment industry, leveraging its advanced customization capabilities and exceptional customer service. With decades of international collaboration and a consistent presence at the prestigious K Show, COSMO continues to showcase its technological prowess and global market leadership.

部落格

From Mold to Marvel: How Jia Thai Delivers Beauty and Precision, One Injection at a Time

When it comes to injection mold manufacturing, there are plenty of options. But few combine technical precision, aesthetic finesse, and decades of experience quite like Jia Thai Industrial Co., Ltd. Founded in 1990 in Taiwan, Jia Thai has quietly built a reputation over the past 30+ years as a reliable partner for high-end mold solutions—especially in the cosmetic and automotive sectors.

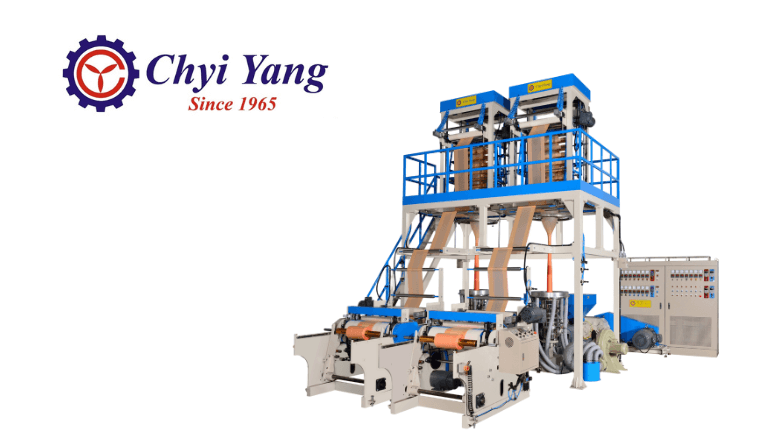

Exploring the Cutting Edge of Plastic Film Technology — Don't Miss Chyi Yang's ABA 3-Layer Co-Extrusion

As a leader in plastic film machinery, Chyi Yang has maintained a solid market position and demonstrated excellence for 60 years. At this year’s TaipeiPLAS, Chyi Yang will showcase its latest ABA 3-Layer Co-Extrusion, renowned for its outstanding cost control capabilities and production efficiency. This machine has become a highlight that industry professionals cannot afford to overlook. This article will delve into the machine's features and invites you to visit Chyi Yang's booth: M0416 to explore the forefront of industry technology.

CHINAPLAS 2025: Shaping the future of film extrusion with high-efficiency co-extrusion system

At CHINAPLAS 2025, Chyi Yang Industrial Co., Ltd. exhibits its innovative multi-layer co-extruded blown film systems. An interview with Sales Director, Antonio Jo.

媒體

預覽

公司

網站

聯絡人

職稱

國家

地址

電話

電子信箱

產品類型

問題與建議

附件上傳

*附加功能

是否需要推薦其他廠商給您呢?

*請填寫此欄位

請在提交前仔細檢查以上資訊,尤其是您的電話號碼和電子郵件。

Experience More Functions For Free

✓Directly contact Taiwanese Supplier

✓Track the progress of your inquiries

✓Manage your previous inquiries

Start to enjoy our premium messaging system and chat with your selected suppliers!

✓Track the progress of your inquiries

✓Manage your previous inquiries

Start to enjoy our premium messaging system and chat with your selected suppliers!