What are the Latest Innovations and Developments in Blow Molding Industry in Taiwan?

After K 2019, it is well known that the whole industry changes its way to deal with business, especially those that have a presence at an international level. After 3 years we have another perspective when it comes to service. We have interviewed and discussed with several Blow Molding suppliers who are the pioneers in this industry in Taiwan, the challenges they have faced during these 3 years of the pandemic and how they solved them to continuously provide high quality service to their customers worldwide. The common challenge for all suppliers faced is the after-sales service since travel restrictions were more difficult for machine manufacturers to send engineers to international customers' factories.

How Taiwan’s Resilience and Innovation Impact The World?

Notoriously, the post-pandemic era has made the Rubber Machinery Manufacturers in Taiwan invest more in their R&D capabilities to improve the features and efficiency of their machinery. This initiative has given an extra boost of recognition around the world for the continuous solutions provided by Taiwanese manufacturers. Some of these innovations include the improvement of energy-saving, reduce labor costs, reduced material wastes, increased material quality, and automate machinery processes.One of the indispensable advantages that have allowed Taiwanese Rubber Suppliers to stand out over their competitors is their automated functions to reduce labor requirements, and water and energy savings.

CHUMPOWER: Providing A Sustainable Injection Stretch Blow Molding Solution in rPET

PET is widely used packaging material for water, beverage, and food industry. It is also highly recycled. Major brands in beverage industry such as Pepsi and Coca-Cola are also planning to increase the rPET percentage within their product packaging. Many countries around the globe have launched environmental strategies such ESG...

Start Your CPP Film Recycling Right Away with POLYSTAR

Cast polypropylene, also known as CPP, is well known for its versatility. CPP is gaining popularity as a more appealing packaging material than polyethylene in many areas because it has higher clarity and better heat resistance. The qualities of the CPP film can be customized to fit specific packaging, performance, and processing needs...

(NEW VIDEO) JANDI'S: JIT's Latest Machinery Development to be Showcase During K-SHOW 2022 , All-in-one Plastic Bag Production Line!

JANDI'S JIT, the best way to produce T-shirt shopping bag. Blown Film→Printing→Bag Making→Die-Cut Recovery, from resin to finished bags, all in one process. Oh! By the way, a brand new option – “Auto-Packing” is available now! Call us for more information and see the machine running at K-2022 booth 17A06!

GENIUS: The Best Waste Film Recycling Solution to Reduce Carbon Footprint

The whole world has been paying attention to environmental protection issues and working on every detail in order to achieve it and contribute to our mother earth, especially after the outbreak of COVID-19. The plastics and rubber industry, which is closely related to our daily activities also pays more attention to this issue and implement practical measures for a better green future...

Challenges in the Post-Covid Era (PART 2): HCI Automation Technology Solves the Labor Shortage Issue

The global market is in turmoil in the post-Covid era, and manufacturers must reduce their cost burden to deal with the unexpected increase in cost control risks. HCI Converting Equipment Co., Ltd. is a leading manufacturer of converting equipment for the flexible packaging industry that is actively developing green technologies...

PRINTPLAS: Precision, No Blur. Your Best Partner in Printing Business!

Printplas Machinery Co., Ltd have been established since 2001 and specialized on the manufacturing of CI & STACK flexographic printing machine in Taiwan. With skill workers and machine R&D department, we are keeping our effort for providing precise, stable, high speed printing machine for our users...

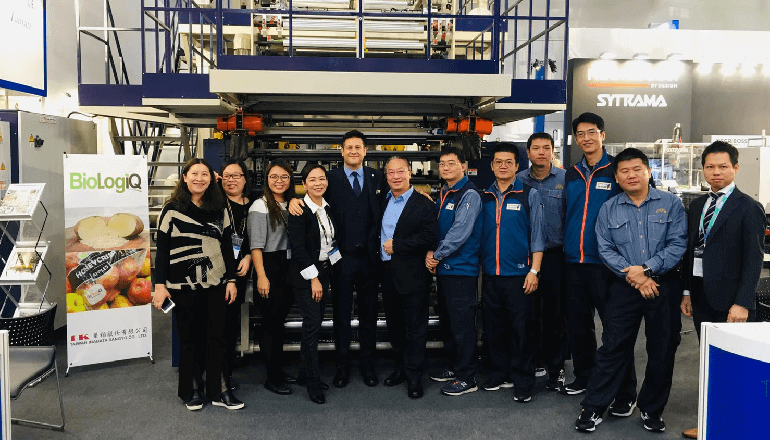

KUNG HSING at K 2022: Blown Film Trends for Food Packaging Films to be More Productive and Energy Efficient

Food packaging film is the largest application in blown film products. When the market gradually accepts three-layer co-extrusion to manufacture food packaging films, Kung Hsing (KUNG HSING PLASTIC MACHINERY) believes that five-layer co-extrusion will be a better and more favorable option in the future.

PP Tray Washing Line for High-Value Application by BoReTech Achieves Efficient Performance

Nextek said that the UK consumes 210,000 tons of food-grade PP per year. In comparison, China generates an average of about 1.5 million tons of plastic tray waste annually. There are 250,000 tons of waste disposable lunch boxes to be recycled, accounting for only 1% of all plastic waste that is recycled.

Challenges in the Post-Covid Era (PART 1): Focusing on the Green Material Innovation Trend, HCI Equipment Significantly Increases Recycling Rates

As a leading company in bag-making machines, HCI Converting Equipment Co., Ltd. has been selected to represent TaipeiPLAS 2022 as "THE GREENER FUTURE MACHINES" equipment manufacturer of the year, demonstrating the strengths of Taiwan's machine manufacturers: adaptability, design and integration capabilities.

KUNG HSING: How to Make Wider Agricultural Films by Blown Film Extrusion Machines?

Do you know the wider the rolls of agricultural film that can be produced in a day, the more cost you will be able to save in the long run? Have you ever thought about this matter and how can we achieve this result? As an experienced agricultural blown film machine manufacturer...