模具與模頭

模具與模頭是塑膠成型製程中不可或缺的關鍵組件,透過精密設計與加工,可協助成型設備如射出機、吹塑機、擠出機等製造出具有高重複性與高精度的塑膠製品。其運作方式為:原料加熱至熔融狀態後注入或擠出至模具內部,經冷卻定型後形成各式所需結構,廣泛應用於包裝、電子、家電、汽車與醫療等產品成型。

PRM-Taiwan 彙整各式模具與模頭解決方案,涵蓋吹塑模具、擠出模頭/模具、熱澆道系統、射出模具、多穴流道系統、模具保護裝置、真空成型模具等機型,適用於單一或多穴腔製品、薄壁結構與高產能製程需求,幫助企業提升模具壽命與製品良率。

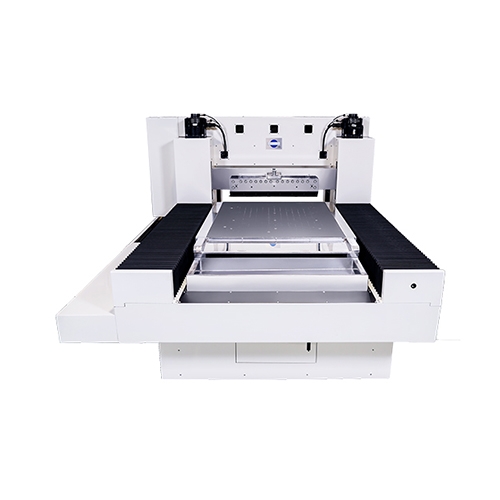

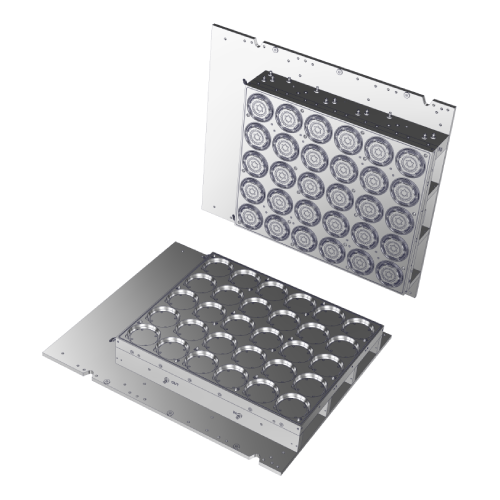

OVER INJECTION MOLD

產品分類 : 射出模具

Over Molding is the process where one material is precision molded over another material, usually rubber (TPE) over plastic, for visual or ergonomic appeal. Very often when the design requires...

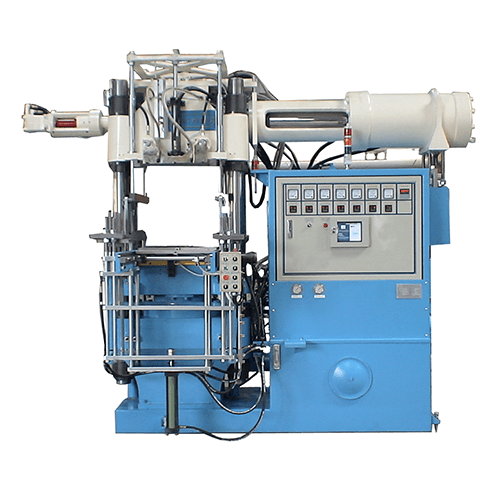

冷澆道橡膠射出成型機

產品分類 : 模具及模頭

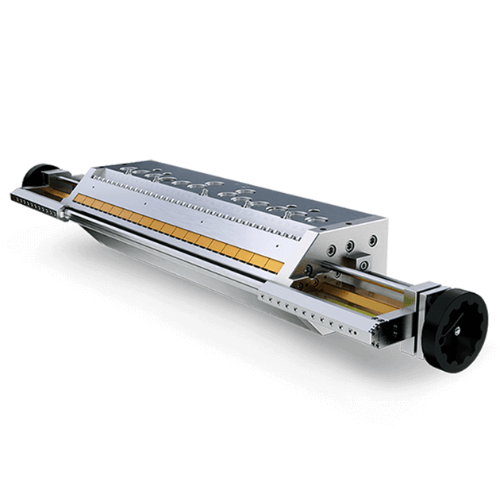

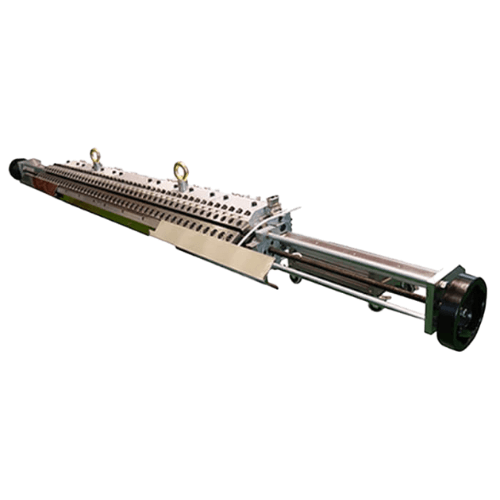

SINGLE INJECTION MOLD

產品分類 : 射出模具

Single Injection Molding is a standard process that YOMURA TECHNOLOGIES excels at. Our YangMei plant is equipped with a resin feeder system to increase yield rates for mass volume production. Ma...

METAL INJECTION

產品分類 : 射出模具

Metal injection molding (MIM) is a metalworking process by which finely-powdered metal is mixed with a measured amount of binder material to comprise a ‘feedstock’ capable of ...