哈囉!普迷們!

睽違已久的 CHINAPLAS ,各家廠商都拿出了哪些壓箱寶呢?這次就由長期駐點在中國的普拉夥伴——Joey 來帶大家深入展館看看今年的展覽現場的盛況!

歡迎想瞭解塑橡膠產業第一手行銷、貿易的消息的廠商,來找PRM喝咖啡、聊行銷!

什麼!你不知道有哪些廠商參展?

還不快點看看PRM為您帶來的CHINAPLAS帶看展

讓美美的~Alice帶大家一睹中國展的風采

歡迎想瞭解塑橡膠產業第一手行銷、貿易的消息的廠商來找PRM喝咖啡、聊行銷☕

????PRM攤位號:7G01

CHINAPLAS 2023 國際橡塑展

聚集海內外各大廠商的塑橡膠產業國際盛會!跟著PRM,帶你行銷全世界!

日期:2023年4月17-20日

開放時間:09:30-17:00

地點:中國.深圳國際會展中心 (廣東省深圳市寶安區福海街道展城路1號)

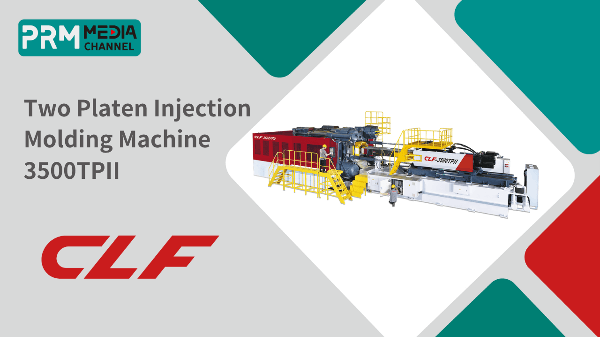

➡️ Maximum injection weight 34 KG.

➡️ High stability, High efficiency, High energy saving..

➡️ Electric Plasticizing Motor substantially increases production capacity and saves energy.

➡️ Direct pressure clamping to make the mold evenly stressed.

➡️ Smooth, stable and powerful.

➡️ Uniform tension force on tie bars for dramatic increase of service life.

➡️ Simplified construction with no wearing problem on toggle clamp.

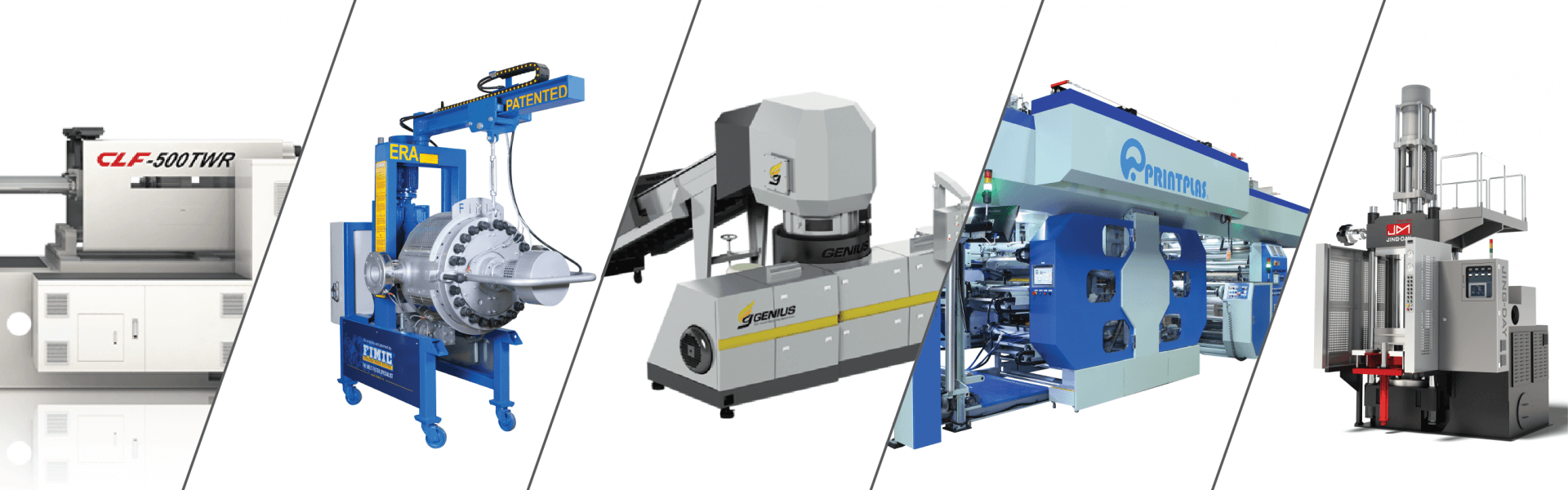

Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc.

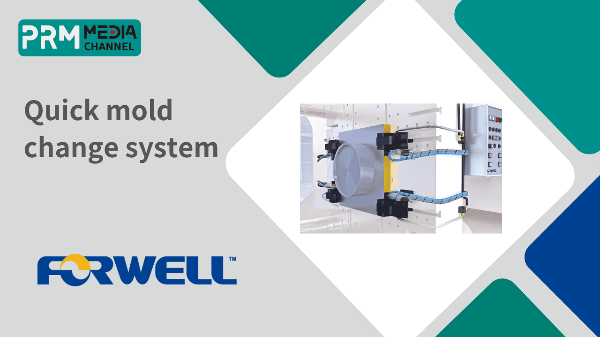

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety.

Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations.

When installing a Quick Mold Change System for your injection molding and mold casting operations there are a number of direct and indirect benefits. Review the following table to see an overview of all of these benefits.

Indirect Benefits

Die Standardization

Press Standardization

Increased Safety

Improved Working Environment

Increased Competitiveness

Direct Benefits

Reduction in Die Change Time

Efficient Small Batch Runs

Reduced Stock Handling

Higher Productivity and Quality

Reduction in Labor Costs