近期更新

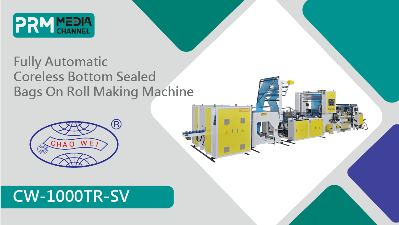

Fully Automatic Coreless Bottom Sealed Bags On Roll Making Machine | CHAO WEI

【Machine Spec & Features】 Bottom Sealed Bags On Roll Making Machine (Coreless) Film width: 600 mm / Thickness: 15 micron E.P.C Control & Rollers Device (E+L, German made) Length: 750 mm x Speed: 135 Pcs/Min Production Line Speed: 100M/Min Servo Driven Shuttle Type Sealing & Perforating Unit Two Sets Triangle Folders For Making Finished Roll With Small Width Machine Maintains High Speed Production By 4 Sets Rewinding Shafts While Producing Small Quantity Of Bags Per Roll 【Company Introduction】 Chao Wei Plastic Machinery is an advanced manufacturer of plastic bag making machine with more than 35 years of experience with ISO 9001 & CE certificates in Taiwan. One of the reasons for the excellence of Chao Wei’s machines is our dedication to research and development.

Plastic Bags on Roll Making Machine Series | CHAO WEI

Introducing a full range of Plastic Bags On Roll Making Machine Series from CHAO WEI, which is a pioneer plastic bag making machine manufacturer in Taiwan with more than 35 years of experience in this field. 【SPECIALTIES OF CHAO WEI】 Bag on Roll Machines T-Shirt Bag Making Machine Side Sealing Machines Bottom Sealing Machines Whole Plant Equipment 【ABOUT CHAO WEI】 CHAO WEI Plastic Machinery Co., Ltd. is an advanced manufacturer of plastic bag making machines with more than 35 years of experience with ISO 9001 & CE certificate in Taiwan. CHAO WEI’s main goal is to enhance the value of machines and to create new performance capabilities that will meet the customers’ production efficiency and profitability.

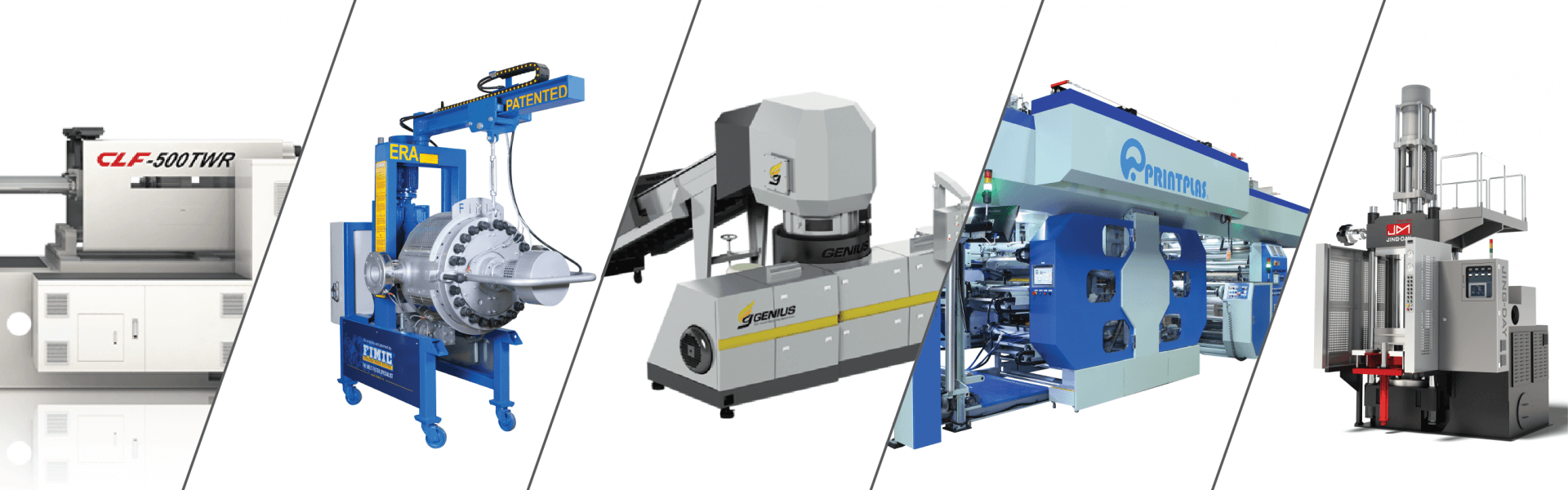

High Speed 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI

High Speed Fully Automatic 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI, TAIWAN [DESCRIPTION of the Machine] ⚡️Special for two lines perforating coreless bottom and star sealing bags on roll. ⚡️In-line triangle folding device for star sealing bags. ⚡️E.P.C. (Edge Position Control) for the film at correct position. ⚡️Japan made servo motors & servo drivers control bag length precisely and high speed production, reducing electric consumption. ⚡️Bag length & production speed can be changed easily from touch screen. ⚡️German made photocell-SICK for accurate printing mark. ⚡️Automatic lift up reel unwinder with air shaft, reducing the number of employees. ⚡️Automatic tension control with AC motor and inverter system for jumbo diameter film roll. ⚡️Two lines automatic roll changing system.