來源:GENIUSPLAS

影片介紹

Machinery in the Video: GENIUS KRIEGER Series - KR-125 Cutter Compactor Recycling Machine

[VIDEO HIGHLIGHTS]

0:00 Plastic Recycling Machine - KR-125

0:28 Belt Conveyor

0:41 Cutter Compactor

1:00 Main Extruder

1:11 User-Friendly Control Panel

1:26 Dual-Piston Filter

1:36 Die-Face Cutting Pelletizing

[KEY FEATURES ]

Applicable Materials: PET, PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS, etc.

Especially for plastic films, foam, woven and non-woven fabric, raffia, washed & squeezed films, flakes, edge-trimmed, and cutting-edge materials.

High torque precision gearbox. Low noise and steady operation.

Die-face pelletizing is expected to reduce manpower costs.

The screw is specially designed for recycled materials based on their characteristics. The unique design ensures full degassing in operation.

SAVE cost, energy, and time.

The single extruder is suitable for clean materials such as injection leftovers and production waste.

[COST SAVING]

Saves energy cost up to 20%

Reduces labor cost as only 1~2 operators are needed to operate the whole plant.

[SUPERIOR FEATURES]

/Compacting & feeding/

The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processing. Increase the highest throughputs for more productivity.

/Multiple Cooling/

Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature.

/Flexible Customization/

GENIUS recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs, presenting a smart and reliable plant.

[VIDEO HIGHLIGHTS]

0:00 Plastic Recycling Machine - KR-125

0:28 Belt Conveyor

0:41 Cutter Compactor

1:00 Main Extruder

1:11 User-Friendly Control Panel

1:26 Dual-Piston Filter

1:36 Die-Face Cutting Pelletizing

[KEY FEATURES ]

Applicable Materials: PET, PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS, etc.

Especially for plastic films, foam, woven and non-woven fabric, raffia, washed & squeezed films, flakes, edge-trimmed, and cutting-edge materials.

High torque precision gearbox. Low noise and steady operation.

Die-face pelletizing is expected to reduce manpower costs.

The screw is specially designed for recycled materials based on their characteristics. The unique design ensures full degassing in operation.

SAVE cost, energy, and time.

The single extruder is suitable for clean materials such as injection leftovers and production waste.

[COST SAVING]

Saves energy cost up to 20%

Reduces labor cost as only 1~2 operators are needed to operate the whole plant.

[SUPERIOR FEATURES]

/Compacting & feeding/

The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processing. Increase the highest throughputs for more productivity.

/Multiple Cooling/

Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature.

/Flexible Customization/

GENIUS recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs, presenting a smart and reliable plant.

精選影片

-

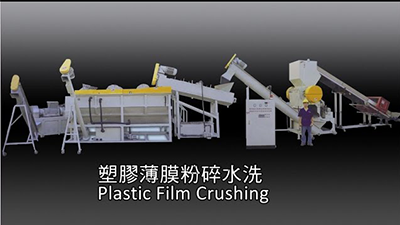

Plastic Recycling Machine - Plastic Film Squeezing Machine | GENIUS

Plastic Recycling Machine - Plastic Film Squeezing Machine | GENIUS

-

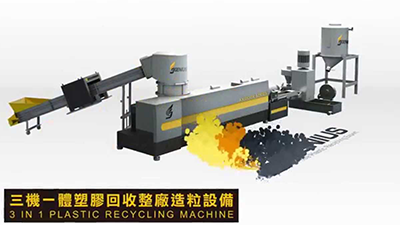

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

-

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

-

Plastic Washing Machine | GEORDING

Plastic Washing Machine | GEORDING

-

Twin Screw PVC Pelletizing Line | TWIN SCREW

Twin Screw PVC Pelletizing Line | TWIN SCREW