押出模具與周邊製造商

政鈺機械於 1989 年,由一群擁有操作押出模具週邊產品以及相關研發經驗的資深設計工程師、技師,共同組成研發設計團隊,以客戶需求為核心,量身訂做產品,深耕業界超過30年,成為全球知名押出模具製造商之一。廠內有完整的加工設備,從設計、加工、組裝以及品檢,所有製程皆在本廠完成,落實良好的品質控管,獲得客戶一致的肯定與讚賞。

2022台北包裝展論壇《包裝趨勢與未來》

台灣包裝協會 x 皮亞恩國際 - 2022台北食品包裝展論壇 線上直播 時間: 2022/06/23 10:00-12:00 地點: 台北南港展覽館1館4樓402C會議室 主題一:以技術新視角展望包裝新未來 講師:台灣莫迪維克 吳逢倉 總經理 大綱: 世界在變/永續發展新浪潮取得減碳永續力之鑰 轉型要備/自動化技術啟動至會製造的效率引擎 新創有譜/食品安全新智能時代創造貨架影響力 主題二:創意食品包裝設計與趨勢 講師:國立台灣科技大學 設計系 許呈湧副教授 大綱: 世界各國對包裝的關注焦點 新電商模式所帶來的新商機 綠色環保包裝的定義與案例 創意好包裝帶來的營收效益

SUNKIST CHEMICAL MACHINERY | Interview at K 2019

We are pleased to interview Willie Huang from SUNKIST, a company from Taiwan with a great reputation for producing the machinery required for flexible and rigid polyurethane foam. This time Mr. Huang gives us a brief introduction of the company and how they are developing new machines that fulfill the new trends in the market, also making emphasis on their social responsibility with the environment. He mentions how Sunkist is facing the current challenges, such as Global warming, giving examples of how the industry is working in plastic reduction. Also, we get their new machinery introduction during K 2019, for more details please click the info card on the video or visit our B2B Platform.

Feedblock | GMA

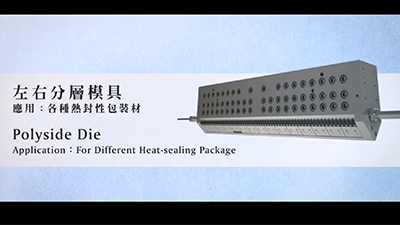

Feedblock - Polyside Die-GMA Two or triple manifold inlet design, plus feed block for multi structures, the width of stripe is adjustable, the adjusting range can be customized, flow adjusting design and adjustable lip can be applied on different thickness product. Application: 1. Heat-sealing food package box 2. Medicine package 3. Recycle material can be used on side to avoid waste Feature: 1. The stripe width is adjustable 2. Plus feed block, for more and different multi structures

Product Enhancement Through In-mold labels & Heat Transfer Films | XIANG IN

Have you ever wondered that your products do not look good and attractive? There is a simple way to enhance your product outlook and increase the quality and profitability. Throughout the interview with Ms. Penny, General Manager from XIANG IN ENTERPRISE, we have discussed advantages by using in-mold labels and heat transfer films to level up your products. Moreover, both of these two techniques not only be used in plastic, but also apply on wood, glass, metal and some particular materials. XIANG IN has been dedicated to developing its technique and improving their inspection. Therefore, the competitiveness of their products could not be replaced due to their strength of expiration and accurate quality inspection.

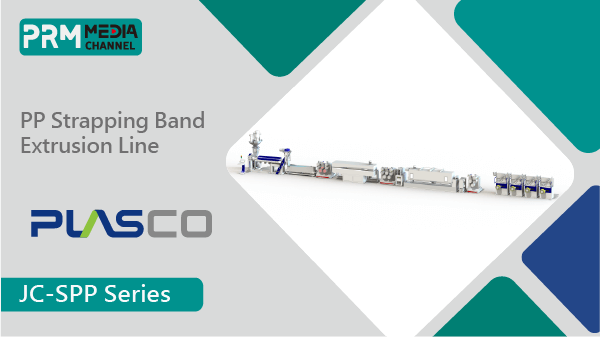

PP Strapping Band Extrusion Line (JC-SPP) | PLASCO

PLASCO's JC-SPP Series of extrusion lines are designed to produce PP strapping bands, which are commonly used for light- and medium-duty applications, such as for securing newspapers and magazines, carton boxes, and pallet freight shipments. 【Machine Spec】 Applicable Material: PP Screw Diameter (mm): 90 / 100 / 120 Strap Width (mm): 5-19 / 12-19 Extrusion Capacity (kg/hr): 180 / 250 / 380 Straps Produced: 4-2 / 8-4 / 8-6 【Application】 Newspaper strap Carton box strap 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

廢料回收設備 | GENOX

K Show開展第四天,PRM-TAIWAN觀察到位於11館的隽諾總是有絡繹不絕的詢問人潮。 百忙之中我們採訪到隽諾的Jamie Jiang,他告訴了我們疫情期間的市場狀況,以及對於未來幾年的預測看法。 最後Jamie提到,在K Show期間有不少合作夥伴、客戶及代理商齊聚一堂,共享這場盛大的國際聚會,還在等什麼?讓我們一起收看隽諾的攤位採訪吧!

Rubber Injection Molding Machine | LIN CHENG

Rubber Injection Molding Machine | LIN CHENG Specializes in rubber injection molding machine, Lin Cheng Technologies Co., Ltd. was established in 1978 and has a strong professional team to manufacture rubber injection molding machine. A series of services we can provide ranges from the purchase of machines to the design and development of molds. Our rubber injection molding machine products are used for electronic components, car parts, oil rings, and so on. In 1997, we were granted the ISO 9002 quality certification.

Surface Modeling 3D Printing | time lapse | Everplast

Surface Modeling 3D Printing | time lapse | Everplast ①The EM3-3505-CMT is an industrial pellet 3D printer manufactured by Everplast from Taiwan. ②This 3D printer is able to utilize compound cement raw material to build products or samples. ③The standard formulation database and material bank are provided along with the 3D printer.

Company Profile of Parker Plastic Machinery | PARKER

PARKER PLASTIC MACHINERY CO., LTD., established in 1989 in Taiwan, is a leading manufacturer specializing in turnkey solutions for blow molding machines. We offer a comprehensive range of high-performance extrusion equipment capable of handling capacities from 5cc to 220L drums. Our commitment to precision and reliability ensures that we consistently meet the diverse needs of our global clientele with excellence. At PARKER, we provide complete technical support, from initial consultations and customized training to ongoing service. Our expert team analyzes production requirements, conducts detailed project studies, and excels in comprehensive blow mold plant planning, optimizing operations for efficiency and profitability. Recognized for superior product quality and exceptional after-sales service, PARKER PLASTIC MACHINERY CO., LTD. has cultivated trusted partnerships spanning over 35 years. Our dedication to excellence is backed by stringent ISO certifications and rigorous internal controls, ensuring consistently high standards. We prioritize customer satisfaction through dedicated support, adding substantial value to our enduring relationships. PARKER continues to innovate in the blow molding industry, advancing technology to enhance machine performance globally. Our machines are trusted across 5 continents and over 113 countries. Our professional sales and service engineers provide prompt and reliable support to meet your needs. PARKER - your trusted partner for high-quality blow molding machines in Taiwan.

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN Introducing automatic injection molding mold change carts system from SANDSUN in Taiwan, which is a leading global customized die and mold change cart system manufacturer. Please refer to the link above to learn about SANDSUN's detailed designs on the mold cart system, including functional advantages such as Hook Type, Motor Roller Type, Real Case, and Electric Mold Trolly. SANDSUN has been providing high quality, secure and efficient injection molding machine mold change cart systems to India, South Korea, Thailand, the United States, Vietnam, Malaysia, Mexico, Brazil, Russia, and many other countries at a reasonable and affordable price for many years. Thus, SANDSUN earned a good reputation in mold change systems and die change systems around the world. Features of die/mold cart system : Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival, and positioning in the process of moving. Device for preventing mold sliding. Die / Mold Cart System co-ordinate with AGV : This video was shot at Chung Yuan Christian University in Taoyuan, Taiwan. The content is the collaboration between the automatic mold cart system and the automated guided vehicle (AGC). The combination of two high-tech devices effectively increases industrial production efficiency and achieves industry 4.0 goals. # SANDSUN Die Cart System Mold Cart System AGC Automated Guided Vehicle Fourth Industrial Revolution Industry 4.0 PRM Media Channel Hizli Kalip Degistirme Sistemleri Enjeksiyon Makinesi Kalip Degistirme

UNDERWATER.TWIN. IPF JAPAN. | RE-PLAST

RE-PLAST EXTRUDER CORP. IPF JAPAN 2023 FAIR DEMO MACHINE: RTU

2024 NPE Orlando Interview | GENOX USA

In this interview with Genox USA, we talk to Mr. O' Donnell about how Genox provides valuable machines and solutions for the plastic and metal recycling markets in America. He shares insights into the company's offerings and outlines their future plans for expansion in North America and Latin America.

Flexo Printing Machine Stack Type - Double Side 2+2 | ROTOFLEXO

ROTOFLEXO Stack Type Flexo Printing Machine - 250 M MIN - Double Side 2+2 - High precision cylinders, anilox rollers, and guiding rollers - Automatic temperature control system - High precision gear transmission system - Closed chamber doctor blade system - Automatic tension, edge, and web guide control - High speed forward and reverse printing desk motion - High precision ball screw designs for key components - Motorised horizontal and longitudinal registration system - Electric heat/drying system - CNC desk position control

Single-stage Injection Stretch Blow Molding Machine | GOLFANG-

Golfang treasures what have been entrusted... customizing special machine with molds for each customer. Golfang specializes in the development and manufacture of " single-stage injection stretch blow molding machine". Provide customers with a whole set of production equipment which includes customized machine and mold. Strictly control the quality and reliability of all assembly parts. Do the test runs repeatedly including mold testing and material testing before delivery. Obtain the most stable molding parameters based on the molding characteristics of the plastic specified by the customer and the adjustment during the bottle production. Meet the customer’s quality and production capacity requirements. Finally, after the machine acceptance, transfer the molding technique to the equipment user and do the personnel training. The equipment ca be run in full-time production with durability, high-efficiency, and high-stability, which creates the best return on investment for the customer. It is also the first choice for producing high-end plastic packaging containers when small quantities, varieties, and high quality are required at an early development stage. The Golfang team has accumulated many years of experience in the field of plastic product: PPSU baby bottles, PC/PMMA lampshades (LED light bulbs), HIPS yogurt bottles, PP/PE/PET medicine bottles, TRITAN water bottles, PET/PETG cosmetic bottles, household product bottles, etc... exquisite packaging containers. Also cooperated with the customers in developing products for well-known brands, include Pigeon, AVENT, Nuby, Yakult, Unilever, LOREAL, AVON, SHISEIDO, Pfizer, etc. Mold development is nothing more than a solution to product market demand. In the field of injection blow molding, Golfang insists on research, design, and manufacture of exclusive molds, and never relies on others, because we know that molds are designed and developed in response to the equipment. When customers evaluate and launch new product according to the market trend, what they need is stable quality and the chance to get ahead of the game. Therefore, with Golfang’s established and mature molding technique, whether it is the mold’s durability (2 million cycles guaranteed) or the delivery time, Golfang is always the most reliable choice for the customer. The common design of mold bases and mold parts is able to save mold costs and improve competitiveness for the customers. It provides them with the most economical solution. Golfang would communicate on product sizes beforehand and suggest for minor alteration. In such a way, Golfang gains good recognition from the customers.

LUYANG | PRM Media Channel Interviews at TAIPEI PACK 2020

Welcome to take a look at our recent interview with LUYANG TECHNOLOGY COOPERATION COMPANY at TAIPEI PACK 2020. Ress from PRM Media Channel interviewed Ms. Mavis Ou, and gathered info about LUYANG's latest technology motors, gearboxes, and drivers. As Ms. Ou stated,unlikely many companies focus only one product line, LUYANG manufacture motors, gearboxes, and drivers all together to provide a complete solution to its customers. This is crucial especially after Covid-19 brings some difficulties in terms of logistics and communication. LUYANG also attends TAIPEI PACK for many years, thus Ms. Ou has a broad insight into and comparison of the previous and current versions of the exhibition. During the interview, we had also a chance to hear her expressions about the market. Thank you for your opinions and questions in advance in the comment section. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

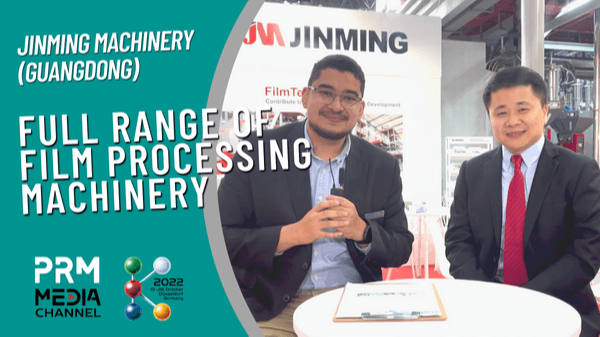

全系列薄膜裝配製造 | 廣東金明

廣東金明是享譽國際的吹膜機械廠,PRM-TAIWAN今天採訪到金明副總裁Simeon Wang。Simeon向我們提到,金明近幾年發展出MDOPE解決方案,它能使薄膜可直接印刷且更具延展性。PRM小編也觀察到金明的風環等關鍵零組件都是出自自家廠製造,因此能對吹出的薄膜達到非常穩定的控制,想一睹金明吹膜機的風采?請手刀點擊收看我們的採訪影片! 另外Simeon也向我們說明了金明的自動化技術在疫情期間解決了許多距離的問題,在K 2022也觀察到永續發展的重要性,期待在K之後市場狀態能夠更加活躍。

Campaign Video|EG-8002 Duplex Center Winding Slitter Rewinder|Nicely

Nicely is preparing to showcase our expertise globally. Our standout model is the EG-8002 Duplex Center Winding #slitterrewinder for #label #paper #processing. With advanced technology, superior tension control, and versatile #automation, it handles diverse #materials seamlessly. Nicely focuses on delivering tailored solutions, offering customized slitter rewinders, automation upgrades, and control system modernization. Each step of our process is carefully designed to address specific customer needs while aligning with the latest industry trends.

2024 TaipeiPlas International Plastics & Rubber Industry Show| TienKang

In this exclusive interview at TaipeiPlas, I meeting with Daniel from Tien Kang to discuss their groundbreaking new technology that utilizes 100% recyclable pellets. Daniel also shares insights into the various materials they use, including EVA, SEBS, TPU, TPEE, and PEBAX, to create the perfect in midsoles and outsoles . Watch to learn more about how Tien Kang is pushing the boundaries of innovation in sustainable footwear production! #TaipeiPlas #TienKang #SustainableTechnology #RecyclablePellets #Insoles #FootwearInnovation

TungYu Energy Efficiency Servo Press(CE) | Tung Yu

⚫Servo motor drive:Servo press use servo motor as the power source, with transmission mechanism and pressure sensing element to provide the required power for the press, and link the guide screw straight joint press head (or center base) to directly provide the required load for the workpiece. ⚫Planetary roller screw:Planetary screw uses a roller instead of a ball between the screw and the nut to greatly improve the rigidity and increase the contact area. The roller rotates around the screw in the same way as the earth orbits the sun, and the loading capacity is three times that of a ball screw, which improves stability and thus extends the life of the screw. ⚫Independent heating platen temperature control system:Provide preheating function before the mold waiting for hot press molding, shorten the hot press molding time and improve the production efficiency. ⚫Energy saving and environment cleaning:The power consumption rate of the servo motor is more economical than traditional motor with pump design.Without hydraulic system there is no oil leakage and low maintenance.It is suitable for working environments with low pollutions, such as electronics industry, biotechnology industry, etc. ⚫Precise movement:Control parameters can be input from HMI, and action commands can be issued to driver through PLC and implement servo motor actuation to achieve high-precision control on working force, speed or position performance. The servo motor is directly connected to the lead screw head (or moveable traverse) through the transmission to have direct required load.The features are to precisely provide key parameters of working force, speed and position in production. ⚫Complete process setting function:It is convenient for the user to set up process parameters and save portable files as backup. ⚫Convenient data tracking and statistical result output:The data and graphs of each cycle could be presented as batch statistical information for tracking by operator easily. ⚫Real-time monitoring of press status:Display of cycle graph and monitoring of press status, sensors and statistics. Real-time production information such as quantity and yield rate to improve the control efficiency and accuracy.

Blow Molding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. [Products List] + Small Blow Molding Machine + Medium Blow Molding Machine + Medium Co-extrusion Blow Molding Machine + Large Blow Molding Machine + Supersize Blow Molding Machine + Double L-Ring Drum Blow Molding Machine + Semi-auto Stretching Blow Molding Machine

Full Electric PK-95CD-E (PE) (Toggle) Single Station Double Heads Blow Molding Machine | PARKER

PARKER PK-95CD-E (PE) (Toggle) Single Station Double Heads Blow Molding Machine

Zipper Bag Making Machine | WORLD STEEL

World Steel-Zipper Bag Making Machine

2024 NPE Orlando Interview | PARKER

We had the pleasure of meeting the passionate Mr. CT Teoh at the NPE show. Mr. Teoh gave us an insightful overview of the innovative PET blow molding machine he brought to the event. This cutting-edge machine features single material concept. Join us as we dive into the details and discover the big news Mr. Teoh has to share!

PVC Medical Tube Extrusion Machine Line (High speed type+Dust proof) | Everplast

The medical tubes produced by Everplast's medical tube extrusion machines have excellent quality and accuracy. They use advanced manufacturing technology and precision machining processes to ensure that each medical tube has accurate dimensions and uniform texture, complying with the strict standards and standards of the medical industry. specification. Whether used for infusion, drainage, or other medical applications, these tubings provide reliable performance and safety. Meets the strict quality and specification requirements of the medical industry. *Contact Info: Web: https://www.everplast.com.tw/ Facebook: https://reurl.cc/r1LZb YouTube:https://www.youtube.com/channel/UC_ziI3cDyRGjV71s8YkV-pg 1.https://www.everplast.com.tw/product/machine-line/medical-tube-machine-line/ 2.https://www.everplast.com.tw/product/machine-line/ 3.https://reurl.cc/QeMrp0 Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

Continuous Thermoforming Machine SL-1220A + SL-520 for Lid Production | CHULIING

【MACHINERY IN THE VIDEO】

CI Flexo Printing Machine - RPM1208-CI | ROTOFLEXO

MACHINERY IN THE VIDEO: CI Flexo Printing Machine - RPM1208-CI | ROTOFLEXO - 8 colors central impression flexo printing machine - High precision stainless-steel impression drum imported from Italy - Automatic water temperature control system - High precision gear transmission system - Closed chamber doctor blade system - Automatic tension, edge, and web guide control - High speed forward and reverse printing desk motion - High precision ball screw designs for key components - Motorised horizontal and longitudinal registration system - Electric heat/drying system - CNC desk position control

Double Injection Mold Expert & Solution | YOMURA

Yomura Technologies Inc. was founded in 1989. With over 30 years of experience, we have been selected as OEM by multiple world-class brands. Moreover, Yomura has the tooling expertise to fabricate complex, high-end molds and the production capacity to manufacture large volumes of precision parts for just about any industry, such as 3C consumer goods, medical, automotive, aerospace products, military & industrial gear and more. 【Service Line】 Single Injection Mold Double Injection Mold Over Injection Mold Insert Injection Mold In Mold Decoration Liquid Injection Molding Metal Injection Micro Molding EMI Shielding Contract Assembly Optical Lens & LED Blow Molding Contract Mold Manufacture Silicone & Rubber Products 【Engineering】 Design and Development Partner Rapid Prototyping Tooling Soft Tooling Process Optimization

GMA 30th Anniversary - Extrusion Dies Empowered by Innovation | GMA

GMA Machinery Enterprise Co., Ltd. has manufactured extrusion-die and has focused on the technology of extrusion & coating dies for many years. In 2019, GMA welcomed its 30th year anniversary with abundant experience in this industry. GMA supports your business & creates wonderful life by the following values: - Excellent Product Performance - Quality Policy - Highly Precision Quality & Products 【Features】 - Complete Production Management - Precision Machine - In-house Chrome-plating Facility 【Industry Involved】 - Industrial Construction Material - Photoelectric Energy Saving - Aviation & Automotive - 3C Digital - Medicine Hygiene - Food Table Wares

薄膜押出設備 | 政鈺

台灣之光押出模具廠-政鈺機械與PRM-TAIWAN在K Show攜手帶來最新的展會消息。 PRM-TAIWAN訪問到政鈺機械總經理Howard Chao,他與我們分享到俄烏戰爭影響了歐洲能源政策,該情況也直接衝擊了整個歐洲市場。 對於今年的展覽狀況來說,Howard表示今年參觀人潮比預期多許多,希望能在展後收穫到更多新的合作夥伴。

Accumulator Blow Moulding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. Detail Specifications : The Abl Series Blow Moulding Machines Are Particularly For Producing The Jerry Can/Drum Tank/Large Article Produtions.It Can Be Combined With Some Accessory Equipments To Increase The Efficiency And Expand The Functions, Such As: After Cooling Unit/Auto Deflashing Unit. The Die Head Can Stock The Melting Resin And Purge The Material For Blowing Formed It Designed With Two Heart Flow Chnnels.Can Make Welding Line-Free To Increase The Strength Of Production. The Tie Bar-Less Clamping Unit Is Consist Of Stiffness Structure Frame And Guiding Devices.Make Sure Deflection-Free Advantage. Also Devise With Precision Rack GgearsO of Bboth Side.Make Synchronize Moving Of Plates. The Blowpin Unit Is Designed For Production Calibrating. That Will Be Suited For Different Demand Of Customer. Accumulator Die Head Blow Moulding Machine. GEFRAN CONTROL SYSTEM -PID Temperature Control System (With High/Low Alarm) -Motor PID Feedback Control Function -300 Points Parison Control -PLC Ladder Program Edlitor -Presscription Record Memory Accumulator Die Head Blow Moulding Machine AUTO-DEFLASHING UNIT This Unit Can Be Excuted Top/Bottom/Handle Deflashing Function By Hydraulic And Pneumatic. And Then Used With Suction Device To Take Out And Turn Over The Production.

Thermoforming Machine CM 100A with Forming Mould PET Clamshell | HONG ZU

Thermoforming Machine CM 100A with Forming Mould PET Clamshell forming area with 25 cavities per mold the products are formed so perfectly. High-efficiency, high-quality thermoforming mold for customer satisfaction.

5G PET Preform Turnkey | KING'S SOLUTION

5G PET Preform Turnkey - 5 Gallon PET Preform Injection Molding Machines & Whole Plant Turn-Key Solution-pet-King's Machinery. FEATURES Select from 2, 4 or 8 cavities mold specifications. Single mold, 4 cavities design. The 2 stage material feed system raises the repeatability rate, lowers the cycle time, and boosts performance. When combined with a secondary cooling system, performance can be doubled. Temperature control via TSR raises temperature accuracy and, working with the accumulator, increases injection speed. Unique economical design is twice as energy efficient as comparable commercial units. we offer a complete set of 5 gallon PET bottle manufacturing equipment: raw material dehumidification and drying system; fixed-volume color additive; quickly stabilizing PET bottle preform molding machine; 4 cavity, hot runner mold; rapid cooling robot; and bottle blowing machine. From raw material to finished product stages, this all-inclusive system promotes high productivity, low cost, and superior quality-the bottle blowing defect rate is kept to a minuscule 0.5%. When water is shortage and lack of quality sanitary sewer, therefore, water container or bottle is convenience to filling in clean water and to carry with to the public. Moreover, bottle is not only for water-use but also oil-use even other liquid-use. King's gallon-size pre-form is one of the best choices in worldwide. Not only does save 20% of shipping cost but also decrease defect of blowing rate down to less 0.5%. And the most critical point is that any color is so clear by King's latest technology and 20 years PET knowledge.

PK-90CSV MHB Single Head Single Station View Stripe Blow Molding Machines | PARKER

Fully electric model machines are available.

Bag Making Machines for Multiple Applications | WORLD STEEL

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, World Steel is dedicated to making technological innovations and manufacturing packaging machines. The company has one of the best engineering crews in the industry to provide total solutions which include design, customization, and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self-adhesive bags, handle bags, sandwich bags, or more, then World Steel is one of the best choices for you.

維達機械注吹再升級!全電注吹機亮相 模內360度; 環標全球首創 (中英文)

江蘇維達機械有限公司,是一家集研發、生產、銷售、服務於一體的科技創新型企業。主營產品注吹中空成型機與精密模具、塑料擠出片材生產線、聚四氟乙烯擠出生產線。作為一家專業的塑料包裝加工設備供應商,維達機械一直致力成為全球客戶值得信賴的合作夥伴,提供全面完善的生產解決方案。