Bio Resin Bag Making Line - JIT Series | JANDI’S

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

Water Transfer Printing Dipping Machine | YHT

Since 1990, YHT has been a manufacturer for Printing High Definition Water Transfer Films, leading the way with short new pattern development time, quick lead time to turn around on film printing orders, and providing many solutions to qualify customers demands. We have been supplying films to many famous brand companies all around the world, and these work experiences have made us irreplaceable on Water Transfer Printing (WTP) business. We not only do printing films, but we also make relevant dipping and wash machines to supply a completed chain of product. 【Advantages of our Water Transfer Printing】 Color and design of the pattern through water pressure Decoration is possible for many sizes, shapes, and flexible products 【Applied Products】 Ski goggles, EVA shoes, electric switches, rifle scope, firearm, crossbows, dog leashes, home appliances, car panels, and steering wheels are all in the scope of WTP process.

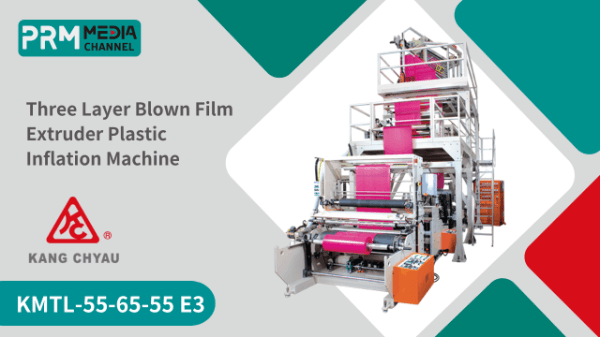

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU

Introducing three-layer blown film extruder machine, in another name called three-layer plastic film inflation machine. From one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the contact button. For any assistance, PRM will be more than happy to assist, please use CONTACT PRM button to leave a comment below. Then we will reply and contact you asap. Machinery in the video: THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE | Model No: KMTL-55-65-55 E3 Film Width: 500-1800 mm Screw Diameter: Ø 40-45-40/45-55-45/55-56-55 mm Suitable Materials: HDPE/LDPE/LLDPE/mLDPE

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine. The main businesses include: 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine and planning of entire plant’s equipment. While the demand for output and quality in 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine worldwide is increasing day by day, our determination for upholding the motto, "Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine products and services to higher standards.

The Cliff's Notes of Chinese Market | PRM What to Say EP2

We are very excited to announce that our general manager, Hero, went to China for CHINAPLAS 2021. It was our pleasure to invite him to PRM Media Channel to share Cliff's Notes on the Chinese Market. Hero mentioned the quarantine process, CHINAPLAS 2021 on-site observation, the escalating demand in China, and the recent Alibaba case in the Video. Moreover, Hero is surprised how the Chinese market digitized, which we should work on. Therefore we are working on creating a borderless environment for our viewers. VIDEO OUTLINE 0:00 Video Starts & Introduce our general manager, Hero 0:50 Experience of Quarantine Process 1:20 Insight into CHINAPLAS 2021 2:23 Domestic Demand in China 4:06 Changes in Chinese Lifestyle 5:44 Brief Talk about Alibaba Case Know us more on PRM YouTube:https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

熱成型設備專家 | ILLIG

PRM-TAIWAN很榮幸邀請到熱成型專家 — ILLIG,大中華地區銷售總監梁振標先生接受採訪???????? 在2022年的K展, ILLIG展出了最新的熱成型設備,也結合這次K展的主題,包括永續性和數位化。 訪談中,梁總監也分享ILLIG針對可回收、生物可分解的PP片材的應用,還有針對未來趨勢的看法。

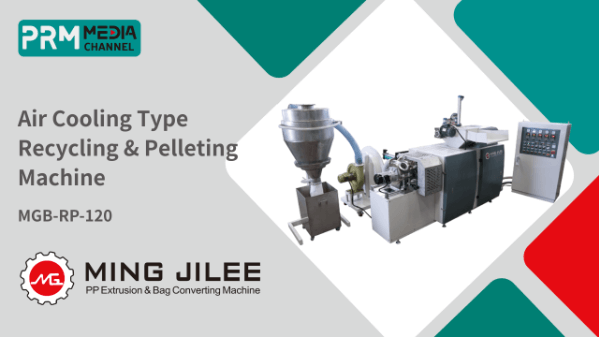

Air Cooling LD/HDPE Recycling Machine, MGB-RP-120 - MING JILEE

Air Cooling LD/HDPE Recycling machine is designs for re-pelletizing PE plastic waste material / t shirt bag die cut wasteThe material can be PE blown film waste, T shirt bag handle die cut waste, etc... Air Cooling Type Plastic Recycling Machine is equipped the power save, the SCR power regulator control. The real power consumption is around 15~20 kg. 1. Machine Specification: (1) Machine dimension a. Main machine : 2,770 (L) × 2,530 (W) × 2,060 (H) mm b. control box : 920 (L) × 420 (W) × 1,660 (H) mm (2) Machine weight : 2,430 kg (3) Power preparation : 45 kg (4) Power consumption : 20 kw 2. Machine Performance: (1) Applicable resin : LDPE / LLDPE / HDPE Waste Film (2) Output a. LD/LLD PE : 50 - 60 kg/hr b. HD/ PE : 40 - 50 kg/hr Air Cooling LD/HDPE Recycling Machine Features: (1) SCR power regular for saving power (2) Rotating die cutting head to get good quality of cutting shape (3) Less space required (4) Extra Cooling fan to cool down the PE material. Air Cooling Type Plastic Recycling Machine Further information: https://www.mingjilee.com/en/product/...

Quick Mold Change - Clamping System | FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

Plastic Recycling and Blown Film Industry in LATAM | RRC Limitada (Polystar's Agent)

Recently, we had an interview with the General Manager and Auditor Accountant of RRC Limitada (Polystar's Chile Agent), a company based in Chile, which supplies South American countries with several kinds of plastics machinery including recycling machines, blown film extruders, bag making machines. They have vast experience knowing the machines and attending international exhibitions, which allow them to have a better understanding of how to assist a customer. RRC Limitada also represents Polystar Machinery, which is a successful Taiwanese manufacturer famous for recycling machinery and blown film extruders lines in many regional markets. Mr. Ricardo Rubilar and his son Rodrigo mentioned how their company's growth opportunities have increased in spite of the devastating impact pandemic has brought to the global economy. In the video, we will see how they explained the importance of having an agent in local markets can give a company greater selling results and enhanced services to local buyers.

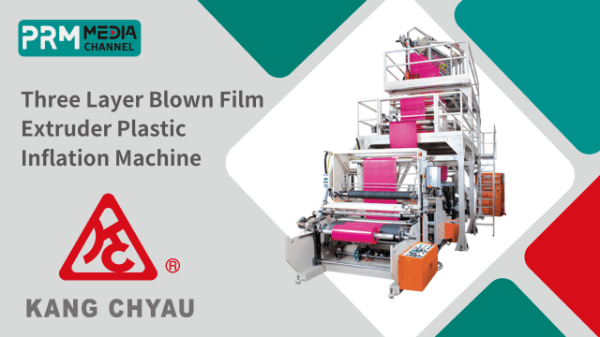

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU-

THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE MODEL: KMTL-55-65-55 E3 Screw/Barrel: 55-65-55 mm Roller width: 1600mm Film width: 1400mm Film thickness: 30mic

2024 CHINAPLAS Interview | JANDI’S

We are here with Tony from JANDI’S at the CHINAPLAS. JANDI’S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag-making, printing, and recycling machines. They obtained more than 30 patents for plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI’S proposes an idea about green innovation. The company develops JIT series integrated plastic bag-making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI’S added the automatic packaging part to JIT series.