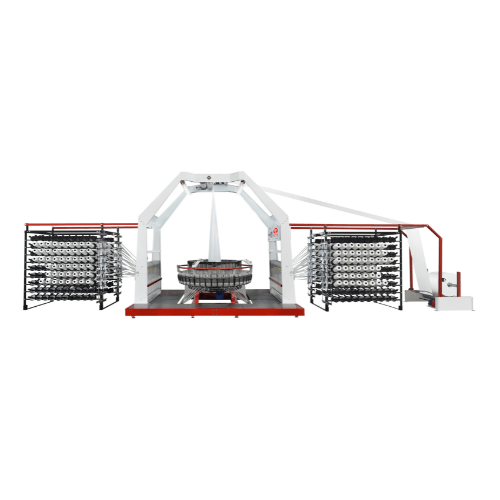

The simplicity and energy saving design of circular looms have led to high efficiency performance with stable quality of weaving.

- Application for woven sack, HDPE woven fabric, and various applications

- Production speed up to 1020 ppm*

- Patented design with enhanced life time of spare parts

- New circular rail design ensures stable shuttle movements

- Slitting device as optional equipment

- Low noise operation

- Lowest possible energy consumption

| Model Number | PH-6/100 | PH-6/100-B | PH-6/125 |

|---|---|---|---|

| Application | Woven sack | Woven sack | Cement sack |

| Shuttle/machine | 6 pcs | 6 pcs | 6 pcs |

| Max. Shuttle Speed | 150 rpm | 170 rpm | 140 rpm |

| Weft insertion up to | 900 ppm | 1020 ppm | 840 ppm |

| Working width, tubular | 48 cm – 95 cm | 40 cm – 80 cm | 48 cm – 120 cm |

| Weft bobbin diameter (max.) | 90 mm | 90 mm | 105 mm |

| No. of warp creel (bobbins) | 720 pcs | 640 pcs | 864 pcs |

| Warp/weft core inside diameter | Φ23 mm–Φ38 mm | Φ23 mm–Φ38 mm | Φ23 mm–Φ38 mm |

| Warp/weft length of core | 215 mm – 230 mm(L) | 215 mm – 230 mm(L) | 215 mm – 230 mm(L) |

| Winding roll diameter (max.) | Φ1200mm | Φ1200mm | Φ1200mm |

| Main motor with inverter | 5 HP | 3 HP | 5 HP |

* depending on weaving construction, fabric, and quality of tapes