分類: PP / HDPE編織袋製造設備

最大限度。機器速度:250M/Min。

標準包括:附加2個烘箱、CPC、進料伺服控制、電暈處理、不停機開捲機、自動。收卷及伺服控制出料

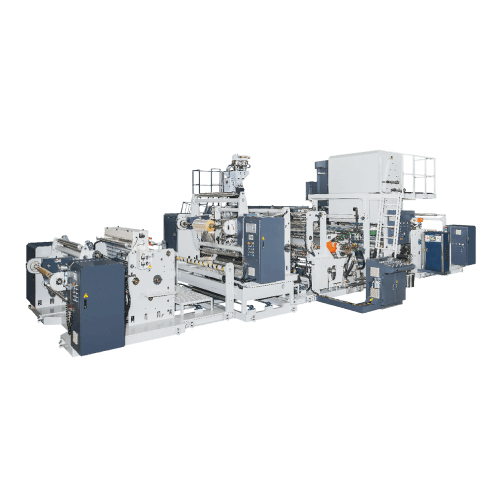

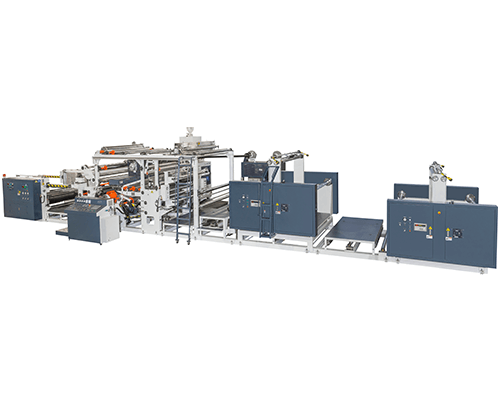

我們的柔性版卷對卷8~12色印刷機採用溶劑型油墨和直接印刷方式,用於有/無層壓的PP編織袋。可進行CMYK色彩組合,獲得逼真的印刷品質,提升包裝價值。

新開發的印刷機提供最大。線速度250M/Min。

- 每個印刷工位的鋼製印版滾筒決定了袋子的長度。當袋子長度不同時要求更換印版滾筒。

- 簡單的套色機制,確保準確的印刷品質。

- 配備自動。張力控制器和磁粉煞車器,在列印前調整張力均勻。

- 配有捲材導引裝置,可控制不同捲材寬度的邊緣位置。

- 採用正時皮帶傳動,運作安靜,傳動精確。

- 與汽車。油墨循環裝置,保持油墨黏度均勻,印刷品質好。

- 可用的 4 層烤箱設施可提供出色的高速乾燥品質。

- 操作員友善的人機介面(HMI)上的全數位化控制設定。

- 根據客戶要求,配備陶瓷輥的高科技刮刀,去除多餘的墨水,以實現最高的印刷作業。

- 可以有自動。用於複捲機連續運轉切片織物捲的換輥裝置,調節恆定的織物張力,並自動。位置糾偏,繞線均勻整齊。

| 模型 | |||

|---|---|---|---|

| 顏色數量 | 8 (4+4) | 10 (5+5) | 12 (6+6) |

| 網路o寬度 | 950 mm | 950 mm | 950 mm |

| 列印寬度 | 900 mm | 900 mm | 900 mm |

| 重複列印 | 350~1200 mm | 350~1200 mm | 350~1200 mm |

| 最大限度o機器速度 | 250M/Min | 250M/Min | 250M/Min |

| 最大限度o列印速度 | Single Side: 180~230M/Min, Double Side: 70~230M/Min | Single Side: 180~230M/Min, Double Side: 70~230M/Min | Single Side: 180~230M/Min, Double Side: 70~230M/Min |

附帶設備

- 雙面電暈處理裝置

- 彩色觸控螢幕式工業電腦作業系統(HMI)

- 汽車。墨泵循環(手動式)

- 汽車。糾偏系統 x 2 套

- 汽車。張力控制(透過磁粉煞車和稱重感測器控制)

- 汽車。墨輥與網紋輥分離液壓系統

- 不停機手動印刷套準系統

- 表面鍍鉻網紋輥 200~300 LPI (依客戶要求)

- 手排式換印滾筒及上布捲提昇機×2台

- 板式氣缸固定在機器上(依客戶要求)

- 靜電消除刷 x 2 件

- 3、4乾燥箱(獨立控制)

- 伺服控制出料裝置

- 伺服控制送料裝置

- 完整的走秀

- 中央位置控制器 (CPC)

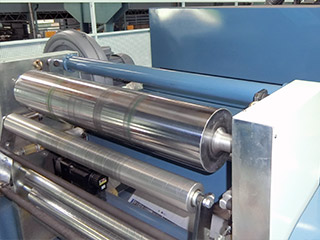

- 帶旋轉接頭的冷卻輥

- 放捲機和複捲機的 3” / 4” 氣脹軸

- 放捲機不停機換輥系統

- “新類型”汽車。複捲機換輥系統

- 數位攝影機監控(8個攝影機)