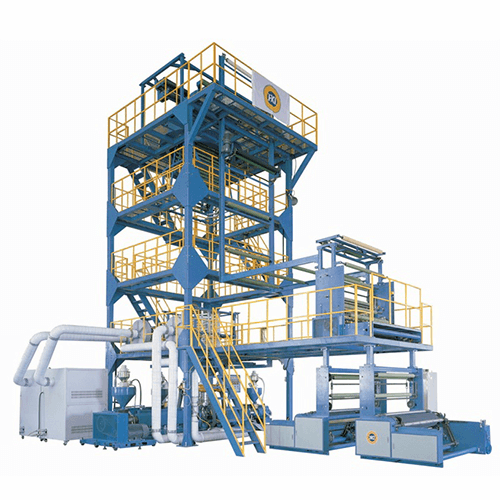

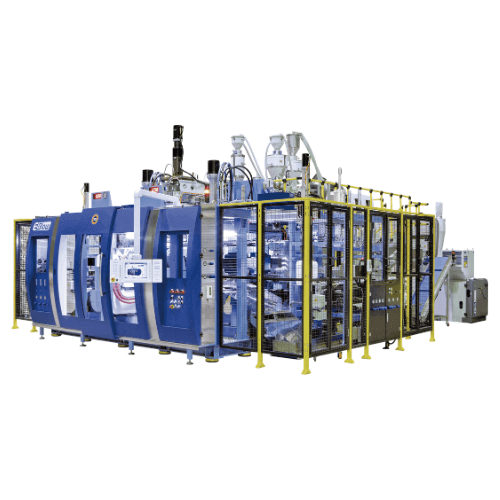

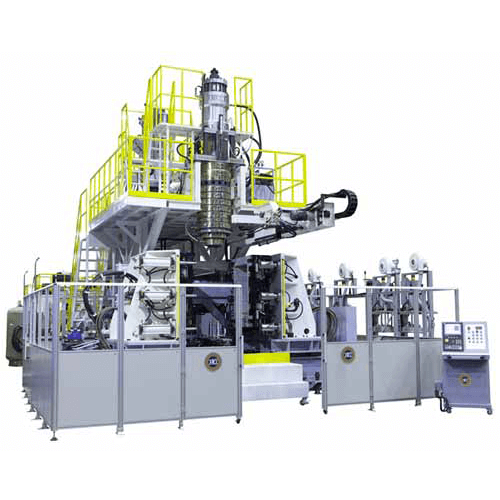

押出模頭有單/雙/三/四/五/六頭,分別可生產從100毫升至30公升之附視窗線及手把塑膠中空製品。

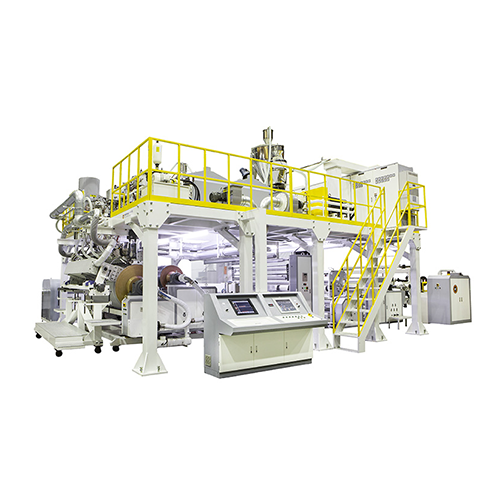

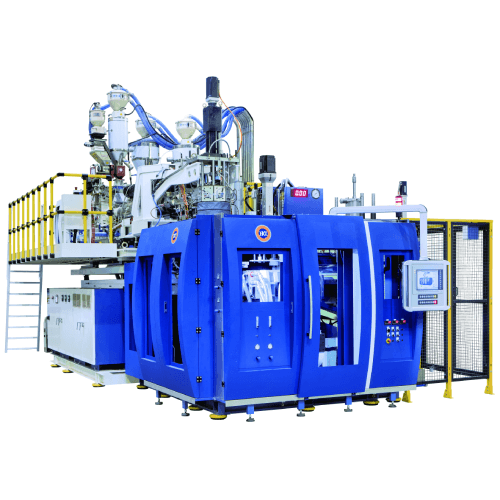

- Precision Control: Equipped with a state-of-the-art servo motor system, this HDPE bottle making machine delivers precise control over the blow moulding process, ensuring uniform quality for every bottle.

- Energy Efficiency: The all-electric design results in up to 30% energy savings compared to conventional hydraulic machines, making it an ideal choice for eco-conscious manufacturers.

- Compact Design: Its space-saving structure makes it perfect for factories with limited room, all while maintaining excellent production capacity.

- Smart Manufacturing Ready: Fully integrated with Industry 4.0 capabilities, enabling real-time data monitoring and process optimization, maximizing efficiency and minimizing downtime.

Ideal for producing HDPE bottles for shampoo, this machine is also versatile enough for other personal care products such as conditioner and body wash bottles. It is particularly suited for manufacturers looking for efficient, high-quality HDPE bottle production.

| 塑料 |

HDPE 5502 grade |

| 產品 |

500~700ml |

| 產能 |

2400pcs/hr |

| 押出機馬力 |

CMG 37kW gear reducer motor +AB vector inverter control (75HP) |

| 押出機螺桿 |

φ65mm,L/D=30,barrier flight design with MADDOCK mixing zone |

| 押出量 |

150kg/hr(max.) |

| 模頭設計 |

HDPE Four Head,Torpedo design with double spider support leg |

| 膜嘴尺寸 |

φ62mm (max.) |

| 油液壓馬達 |

multi-connecting rod with self-lock |

| 夾模板 ( H x W ) | 300x600mm(HxW) |

| 夾模力 | Design 140kN(14tons),Operate 100kN(10tons |

| 夾模距離 | 280~425mm,fixed |

| 模具厚度 | 280mm,fixed |

| 移模行程 | 630mm(max.650mm) |

| 壓力值 | |

| 冷卻系統 | NA |

| 除胚裝置 |