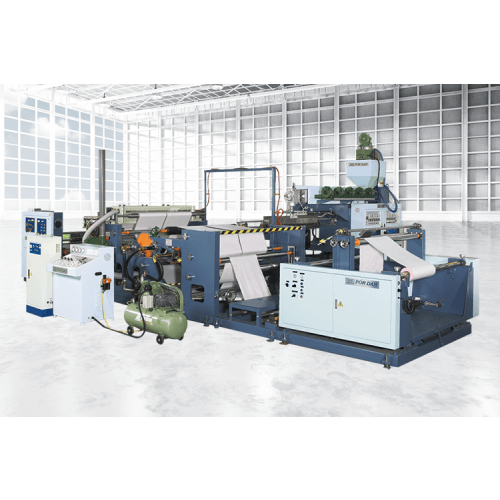

分類: PP / HDPE編織袋製造設備

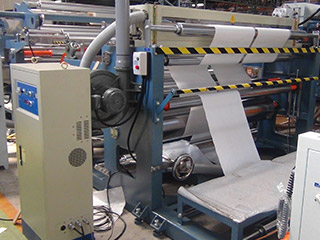

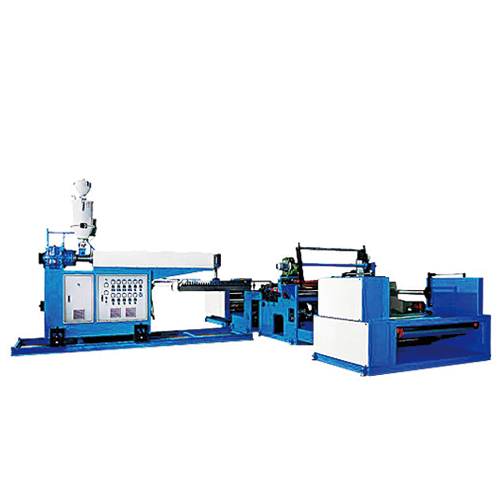

單面轉棒外層壓機用於在機織物、BOPP薄膜、紙張、貨櫃(FIBC)等基材上塗覆薄層聚烯烴(主要是LDPE/PP),用於防潮、防塵,結構夠堅固。

- 採用“Turn Bar”,一台擠出機一次完成雙面貼合。

- 採用SCR控制省電,精確的PID溫度控制器。

- 機器採用PLC程式同步控制,透過人機介面操作簡單,可實現收據設定、溫度控制、計長、警報記錄等功能。

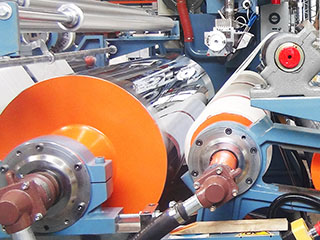

- 放捲機煞車系統為夾式氣動煞車,確保機器持久運作。

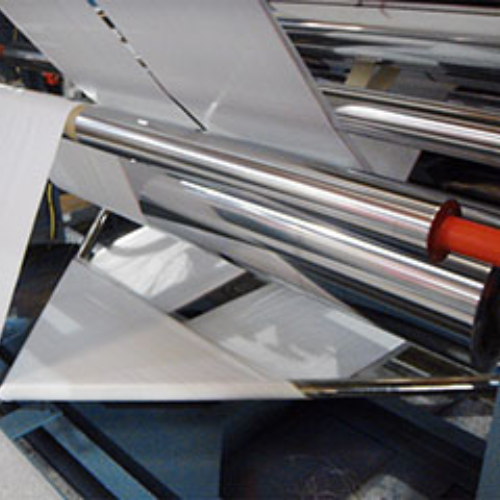

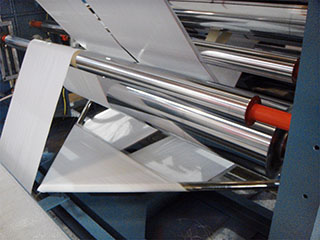

- 採用預熱輥和加熱管對材料進行處理,達到良好的黏貼效果。

- 鏡面冷卻輥(可選)使袋子具有閃亮的外觀,為印刷前提供光滑的基礎。

- 印刷BOPP雙面印刷標記追蹤系統(可選),透過精確的張力控制器、色標感測器和軟體進行追蹤。

| 模型 | |||

|---|---|---|---|

| T 型模具長度 | 1650 mm | 1850 mm | 2000 mm |

| 螺桿直徑 | 90 mm | 100 mm | 100 mm |

| 產品寬度 | 500~1400MM (Single Side), 400~650 MM (Double Side by Turn Bar) | 700~1600MM (Single Side), 400~750 MM (Double Side by Turn Bar) | 900~1800MM (Single Side), 400~850MM (Double Side by Turn Bar) |

| 擠出能力 | Max. 150 kgs/hr | Max. 200 kgs/hr | Max. 200 kgs/hr |

| 機器速度 | 40-90M/MIN (Single Side), 30~70M/MIN (Double Side by Turn Bar) | 40~80M/MIN (Single Side), 30~60M/MIN (Double Side by Turn Bar) | 40~90 M/MIN (Single Side), 30~60 M/MIN (Double Side by Turn Bar) |

附帶設備

- 自動裝載機:1套

- 空氣壓縮機 (1 HP): 1 套 (適用於 FD-LA90/1650(ST-B) & FD-LA100/1850(ST-B)

- 空氣壓縮機(3馬力):1組(適用於FD-LA100/2000(ST-B)

- 邊紗破碎機+旋風分離器

- 邊紗收集絡筒機:1套

- 攪拌機:1套

- 冷卻水塔:1套