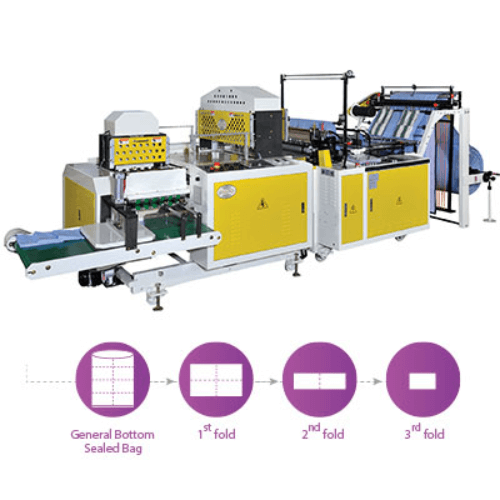

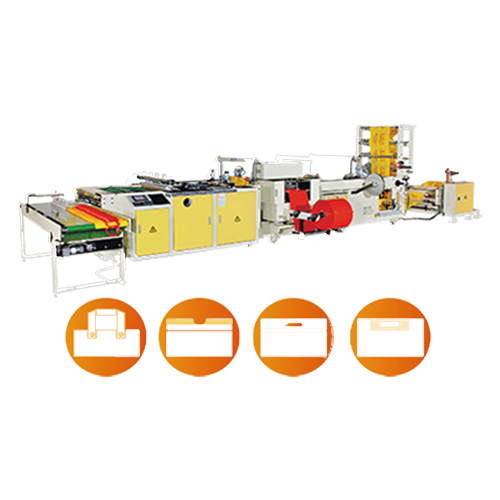

| Model | 32 | 32 | 32 | 42 | 42 | 42 |

| 2 wire | 3 wire | 4 wire | 2 wire | 3 wire | 4 wire | |

|

Machine dimension (cm) |

L : 230 W : 153 H : 195~230(-35) |

L : 230 W : 178 H : 195~230(-35) |

||||

|

Machine center (m/m) |

410 | 270 | 200 | 500 | 330 | 250 |

| 430 | 530 | |||||

|

Packing width (m/m) |

130~350 | 130~220 | 130~150 | 130~450 | 130~280 | 130~200 |

|

Packing length (m/m) |

230~580 | 230~580 | 230~580 | 230~580 | 230~580 | 230~580 |

|

Feed sensor (SET) |

2 | 3 | 4 | 2 | 3 | 4 |

|

Printer sensor (SET) |

2 | 3 | 4 | 2 | 3 | 4 |

|

Fastest speed (Cycles / Min) |

10 | |||||

|

Outer bag MAX Diameter (m/m) |

500 | |||||

|

Total power (kw) |

6.5 | |||||

|

Voltage (v) |

220 | |||||

|

Outer bag thickness (m/m) |

0.025 | |||||

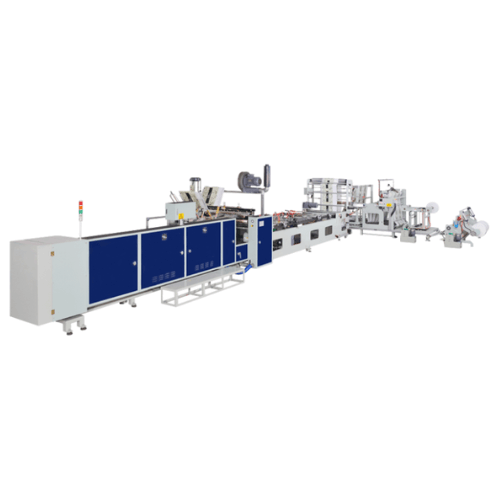

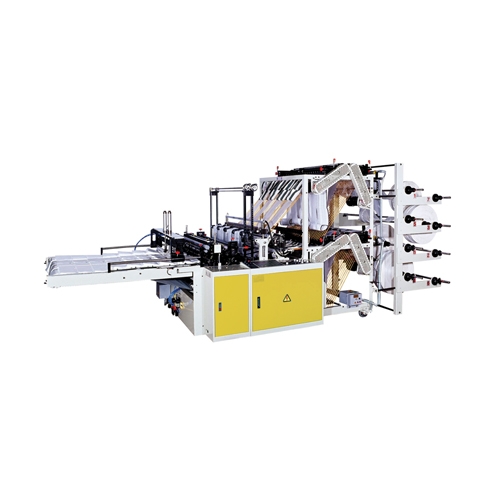

Improve the overall productivity of shopping bags for reducing labor intensity.

Automated production from film roll-in-sealing-cut-bag-punching-fold-folding.

# Improve quality yield rate

.full servo system connection

# Raise resources for recycling

.1 person responsible for 2-3 sets of bag making machines

# Raise the concept of environmental protection resources

.Packing line production

.Reduce 1-3 bottom sealers

.Reduce sealing heat source

# Space Reuse

.Reduce bagged finished products and transport them to packaging area

.Products which directly shipping after the automatic packaging machine

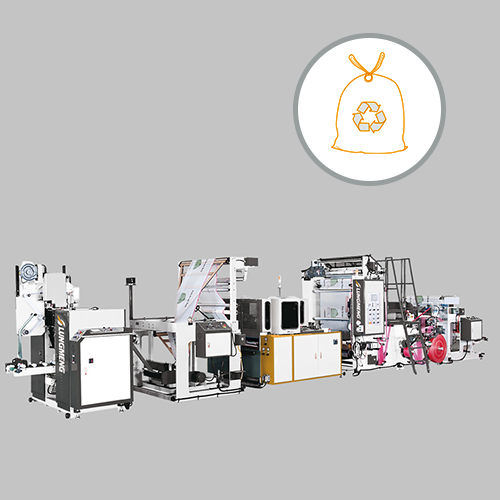

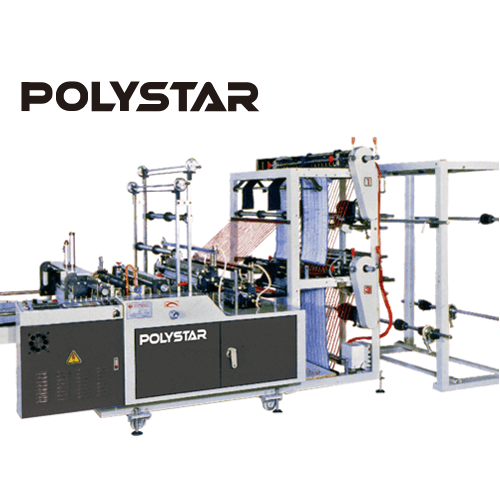

Automated production from film roll-in-sealing-cut-bag-punching-fold-folding.

# Improve quality yield rate

.full servo system connection

# Raise resources for recycling

.1 person responsible for 2-3 sets of bag making machines

# Raise the concept of environmental protection resources

.Packing line production

.Reduce 1-3 bottom sealers

.Reduce sealing heat source

# Space Reuse

.Reduce bagged finished products and transport them to packaging area

.Products which directly shipping after the automatic packaging machine