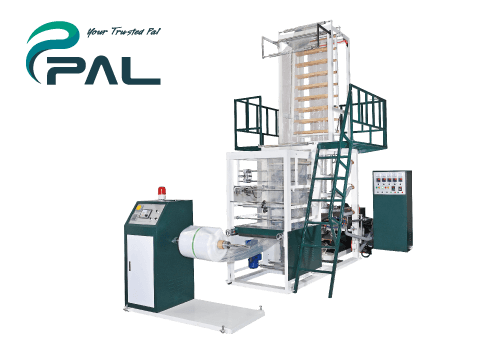

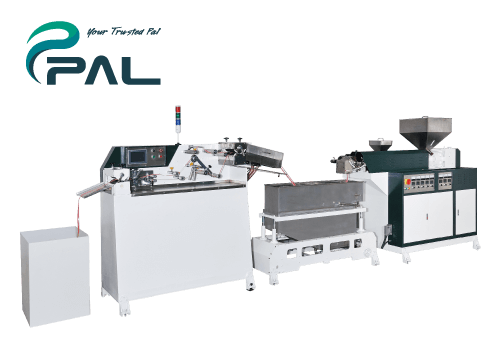

Machine Model: 45 / 55LD-Z

Machine Features:

- High speed zipper film extrusion - Stable LDPE extrusion at 8-12 M/min

- Zipper film die head - One die, one size. available sizes listed in specification chart

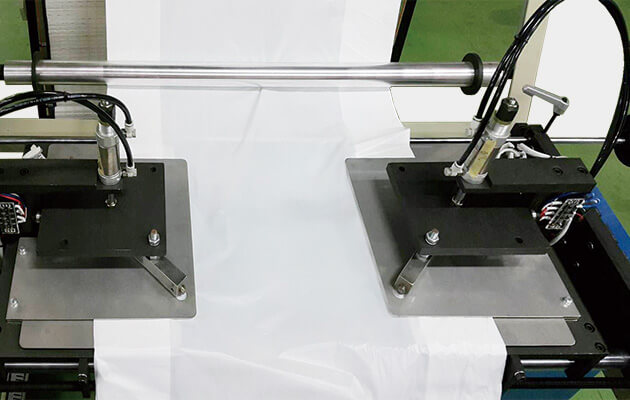

- Auto width adjustment - Self-correction for extrusion width upon detection out of range

- Closure examination - Alarm when zipper not closed properly

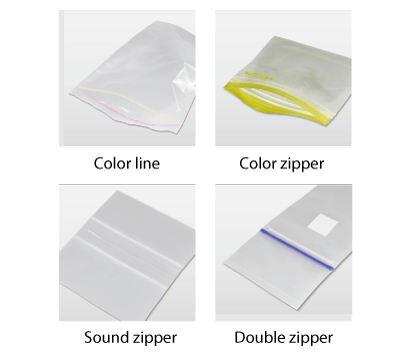

Optional Device

- Color-line sub-extruder - Extra 20 mm for secondary color

- Color zipper sub-extruder - Extra 25 mm for color zipper

- Sound zipper device - Popping sound and hand notify users of secure closure

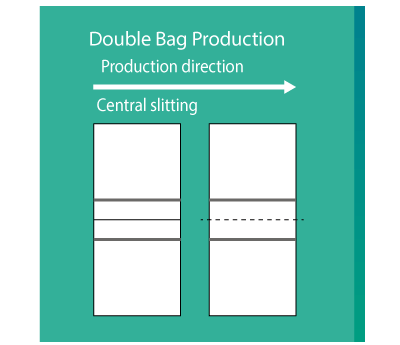

- Double bag die head - Output twin zipper lines with single die head and slitted during converting

機器型號:500/750/900SWZ-V

- 夾鏈膠膜系統 - 夾鏈與膠膜同時押出。可配置整線生產(押出機-印刷機-製袋機)。

- 夾鏈封口系統 - 邊封裝置和給料輪專為夾鏈膠膜生產而設計。冷壓裝置將封口完成袋在矽利光皮帶上冷卻,以避免夾鏈變形。

- 雙袋系統 - 小袋與2個夾鏈押出,並在製袋機上冷邊剖。

- 封切速度同步 : 入料速度採用變頻器控制速度,配合主機速度,無須調整,操作容易。

- 西德SICK電眼追蹤 : 印刷位置精確追蹤

- 觸控式螢幕操作面板 : 人性化操作界面可隨時調整參數,掌握生產狀況。

- IC電子迴路自動控制 : 自動控制系統採用插座式設計,易於更換。

- 警示停機 : 溫度異常/無料/電眼追蹤失誤達三次,警示&自動停機

可用的選用設備:

异形斜线封口-

• 斜封口装置密封有边折的胶膜,以形成平袋的矩形底部。主要用于重型包装。

輔助封口-

• 在袋子的特定位置進行熱壓和封口,例如在4層和2層位置之間的折角間隙,以達到穩定可靠的封口。

輔助間歇式超音波封口-

•將夾鏈碾壓及封口在夾鏈膠膜和夾鏈條上,以達到不漏水和良好的邊封表現。

各式沖孔-提把/圓形/切割/蝴蝶孔/其他-

•各式沖孔有標準尺寸及客訂尺寸可供選擇。固定於機台側邊。

中分條裝置-

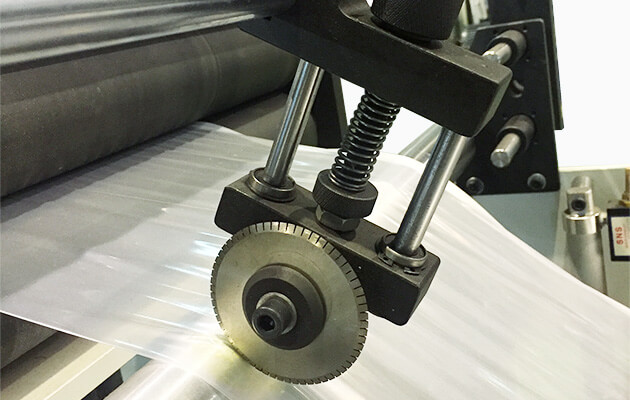

• 在送料中以固定分條刀剖開膠膜。

連續式點斷裝置-

•連續鋸齒刀是固定的,切出與進料方向平行的點斷線。

鋸齒式沖孔-

•針對厚膜沖孔的鋸齒沖孔。

Machine Model: 45INLL / 45INLL-AB

Machine Features:

- High-speed extrusion @30-80M depending on style

- Extrusion for both PP & PE based profiles

- Special formulated coating layer attachable to both PP & PE film minimizing stock requirement. Low seal temperature material can increase production efficiency.

- Closure malfunction alarm - Alarm when zipper profile closure not performed properly.

- (Zipper profile mould available by standard and customized)

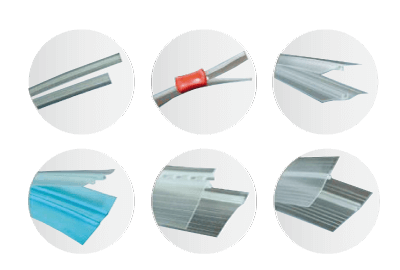

Available zipper styles:

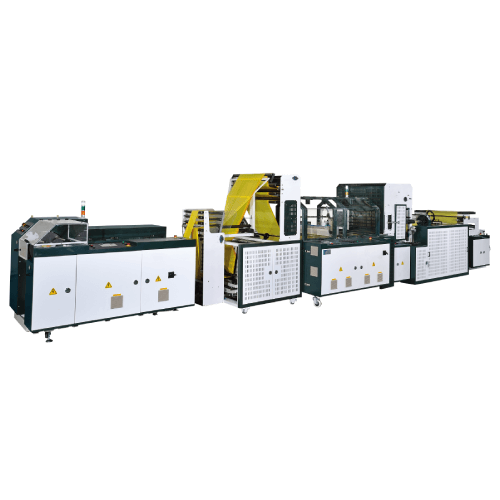

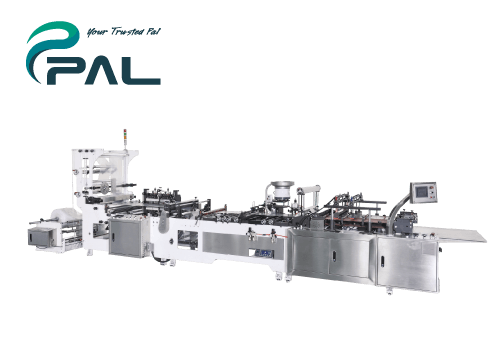

Machine Model: 500 / 750 / 900 ZPB-V

Machine Features:

- Servo driven - High speed and accuracy @140 pcs/min

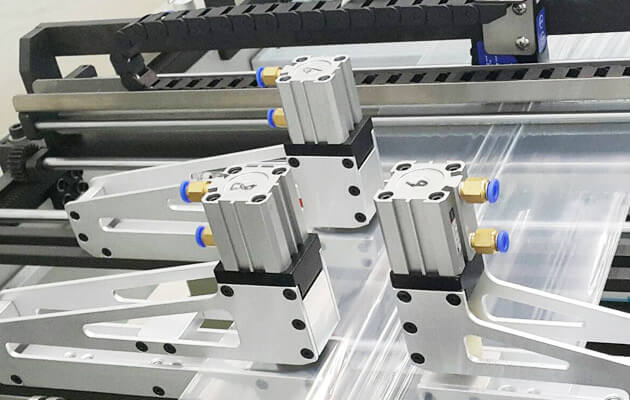

- Zipper attachment unit - Stable attachment feeding and sealing continuously with strong sealing performance

- Also available with twin line deli system

- Auto-stop for profile jamming - Lever mechanism and machine automatically stop when zipper profile is jammed

- Malfunction alarm / stop - Abnormal temperature / no material feed / photocell track miss

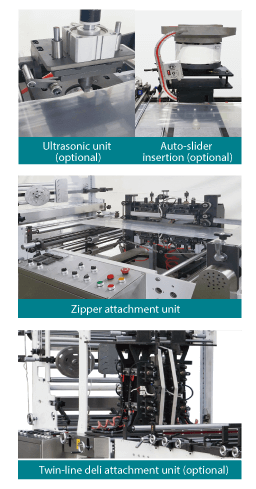

Available Optional Device:

- Auxiliary ultrasonic sealing - Crushing zipper for easy sealing

- (Various hole punches - Kidney, euro, round punches, etc.)

- Trangle folding device - Folding sheet film in half for bag making

- Irregular sealing bar - Cut & sealing specific shape such as a grape bag bottom

- Auto-slider insertion @60-100 pcs/min depending on slider style (model: ZPB-V+SD)

Zipper Profile Insertion & Attachment

Regular blown film

- Suitable for different sizes and different zipper styles

- Suitable for PP & PE film and zipper

- Line speed max @30M/min

| Model | Cutting length (inch) | Cutting width (mm) | Cutting speed (strokes/min) | Film thickness (mm) | Tolerance | Power |

Machine dimension L x W x H (cm) |

|

| SWZ-V | 500SWZ-V | 60-450 | 60-450 | 20-140 | 0.012-0.1 | ±1 | 3.5 | 300 x 145 x 215 |

| 750SWZ-V | 60-700 | 60-550 | 20-140 | 0.012-0.1 | ±1 | 4 | 300 x 160 x 215 | |

| 900SWZ-V | 60-850 | 60-650 | 20-140 | 0.012-0.1 | ±1 | 4.5 | 300 x 175 x 215 | |

| ZPB-V | 500ZPB-V | 60-450 | 60-450 | 20-140 | 0.012-0.1 | ±1 | 4 | 780 x 145 x 215 |

| 750ZPB-V | 60-700 | 60-550 | 20-140 | 0.012-0.1 | ±1 | 5 | 780 x 160 x 215 | |

| 900ZPB-V | 60-850 | 60-650 | 20-140 | 0.012-0.1 | ±1 | 5.5 | 780 x 175 x 215 | |

| ZPB-V+SD | 500ZPB-V+SD | 60-450 | 60-450 | 20-140 | 0.012-0.1 | ±1 | 4.5 | 950 x 145 x 215 |

| 750ZPB-V+SD | 60-700 | 60-550 | 20-140 | 0.012-0.1 | ±1 | 5.5 | 950 x 160 x 215 | |

| 900ZPB-V+SD | 60-850 | 60-650 | 20-140 | 0.012-0.1 | ±1 | 6 | 950 x 175 x 215 |

| Co-extrusion Zipper Profile Extruder | |||||||

| Model | Screw diameter |

Screw length L/D |

Heater cap. (kw) |

Main motor |

Max. extrusion output (kgs/hr) |

Auto temp. controller |

Machine dimension L x W x H (cm) |

| PL45INLL | Ø45 | 01:30 | 17 | AC 10HP | 20-80M | 5 points | 600 x 100 x 170 |

| PL45INLL-AB | Ø45+Ø25 | 01:30 | 22 | AC 10HP | 20-80M | 8 points | 600 x 100 x 170 |

| High-speed Zipper Film Extruder | |||||||||

| Model |

Screw diameter (mm) |

Screw length L/D |

Film blown width (mm) |

Film blown thickness (mm) |

Line speed (M/min) |

Auto temp. controller | Main motor | Takeout motor |

Machine dimension L x W x H (cm) |

| LD45-Z | 45mm | 01:30 | 100-350 | 0.04-0.125 | 4-12 | 5 points | 10HP | 1HP | 440 x 130 x 400 |

| LD55-Z | 55mm | 01:30 | 180-600 | 0.04-0.125 | 4-12 | 5 points | 16HP | 1HP | 440 x 160 x 400 |

| Available Standard Die Heads | |||||||

| Die diameter (mm) | Ø60 | Ø70 | Ø80 | Ø100 | Ø120 | Ø150 | Ø180 |

| Single bag film width (mm) | 60-85 | 60-85 | 85-120 | 120-160 | 160-200 | 200-240 | 240-280 |

| Die diameter (mm) | Ø200 | Ø220 | Ø250 | Ø270 | Ø300 | Ø320 | Ø330 |

| Single bag film width (mm) | 280-320 | 320-360 | 360-400 | 400-440 | 440-480 | 480-520 | 480-520 |

| Die diameter (mm) | Ø60 | Ø70 | Ø80 | Ø100 | Ø120 | Ø150 | Ø180 |

| Double bag film width (mm) | 10-25 x 2 | 10-25 x 2 | 25-45 x 2 | 45-65 x 2 | 65-85 x 2 | 85-105 x 2 | 105-125 x 2 |

| Die diameter (mm) | Ø200 | Ø220 | Ø250 | Ø270 | Ø300 | Ø320 | |

| Double bag film width (mm) | 125-145 x 2 | 145-165 x 2 | 165-185 x 2 | 185-205 x 2 | 205-225 x 2 | 225-260 x 2 | |