尼龍 6 工程塑膠 - NA1200GK45

產品分類 : PA樹脂/尼龍

45%玻璃纖維增強 (本色-高剛性、高耐衝擊) 應用說明:手工具、電動工具、園藝工具用,汽車、機車、腳踏車零組件用,運動器材零組件用,電子、電器外殼及零組件用,O.A.辦公室零組件用,水資材用,醫療復健器材。

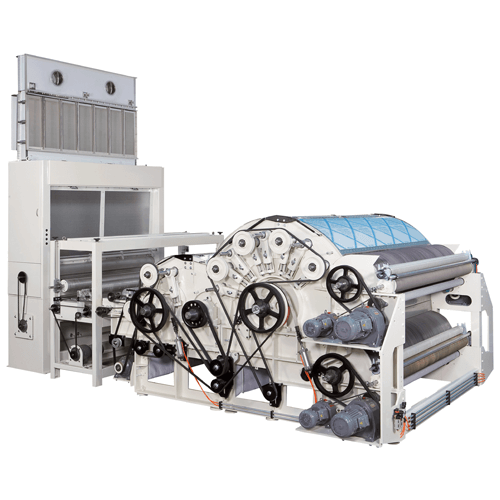

Utraflex / Utraflex-H (UV-LED機型)

產品分類 : 膠板印刷機

Utraflex / Utraflex-H (UV-LED機型) Ultraflex衛星式UV-LED機型提供高品質及高色濃度之產出,同時不排放VOCs使它成為環保製程的好選擇。Ultraflex-H衛星式多功能機台將三項技術合而為一,包含UV-LED應用、溶劑/水墨應用及大輪設計。透過Ultraflex-H印刷業者在擁有UV-LED優勢之外也可以在印刷工作有需要時隨時切換至溶劑/水墨應用。若您正在尋求一高彈性、高效率及高CP值的機台,您可參考此系列來客製。

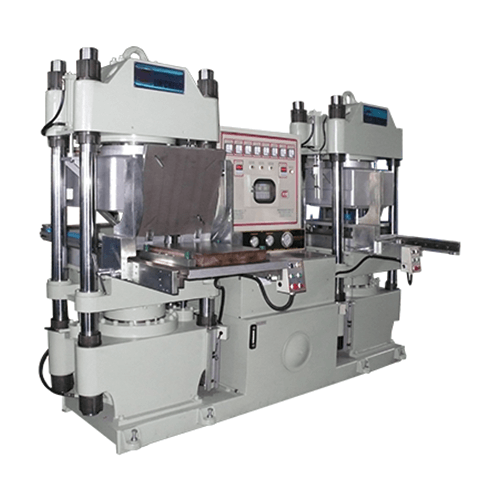

DG-EP 系列 伺服馬達驅動射出成型機

產品分類 : 全自動射出機

•於低速範圍有極優秀之安定控制 •長時間高壓的射出保壓性能 •30ms高應答射出 •幾乎與電動式射出機一樣的電力消耗 •射出速度及壓力閉回路控制,高度之成型安定性 •關模機構使用免潤滑軸套+黃油潤滑系統

旋轉塔ABC三層膜吹袋機

產品分類 : 吹膜押出機

The ABC three-layer co-extrusion machine is your ideal choice for producing high-end plastic products, such as shrink films, agricultural mulches, electrical insulation films, packaging films, medical packaging films, stretch hood films. The raw material formula for each layer can be customized respectively according to your requirements. The oscillating haul-off unit provides excellent film gauge randomization, ensuring the production of high-quality and wrinkle-free films. The oscillating haul-off unit is also rather durable, and its equipment lifespan is much longer than the rotary die. Suitable for producing three-layer films for specific functions Recycled materials or CaCO3 is applicable to the middle layer in order to save material costs Die and air-ring specially designed for producing high-quality three-layer films 360° Oscillating Haul-off unit improves film thickness uniformity EPC (Edge Position Controller) Full customization according to your specific requirements

ST-800 / 900

產品分類 : 工業機器人

.整體結構設計改良 造就輕盈機身 .相較THS系列 重量減少20KG .與HX系列比較 減輕將近10KG .輕量化機身 大幅減輕馬達負荷 & 增加壽命性能

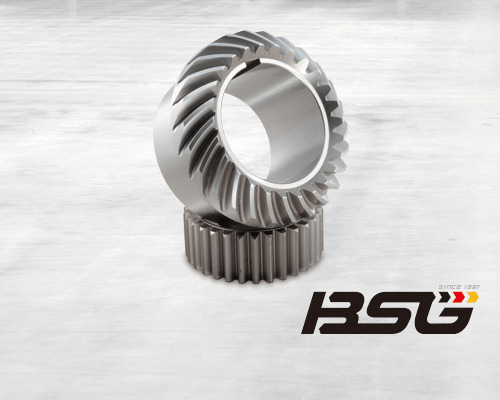

Spiral Bevel Gear

產品分類 : 齒輪

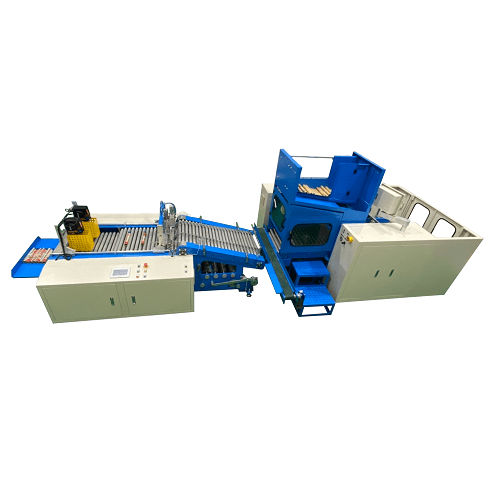

SIX-SHAFT AUTOMATIC ALUMINUM FOIL / CLING FILM REWINDER AUTOMATIC REWINDING & SHRINK FILM PACKAGING MACHINE (AH-6S + TPG50)

產品分類 : 分切機和複捲機

AH-6S connected to TPG 50, the fully automatic production line, fully automatic operation system. Use a conveyor to combine two models for manufacture. Machine will automatically rewind material after input paper core. When the roll is finished and unloaded, it is carried to the packing area for automatic packing process. If the packing function is not used temporarily, TPG50 can be switched to delivery mode. Or use the conveyor which connects 2 machines to unload products from the side. This production line achieves automated manufacture. It saves time and manpower of moving materials and rolls from machine to machine. TRU-BRUTE Machinery always provides the beneficial collocation of machine for you. Welcome to consult machine with us. We will at your service.

壓空成型+外型裁切+自動計數堆疊 SL-1220A + SL-520

產品分類 : 真空成型機

Flexible package solutions for various budgets and production needs. Fine processing competence fit for all standard and few specific plastics. Cold forming under high pressure load for high capacity and low cost. A cut of labor and waste via direct retrieval of plastic waste Low power consumption due to 30% saving energy and 40% compressed air cutting. A central control unit for easy operation and handy maintenance. • Rich experiences in package equipment with a tailor-made solution for you