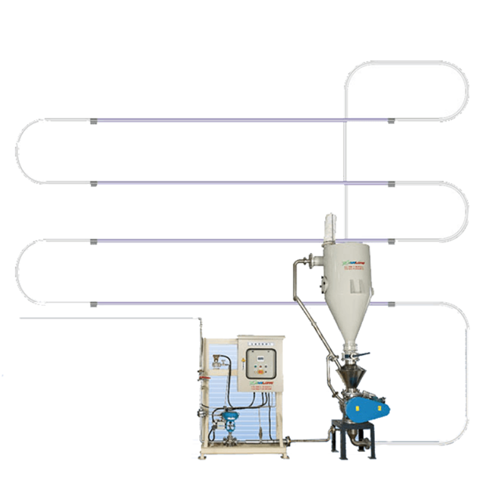

高壓低速輸送系統 (粒子)

產品分類 : 裝載機與運輸機

Suitable for a variety op plastics, rubber, crops, and mineral power, automatic conveying and storage. This system, has no distance limitations, no powder/resin loss in the conveying process, and it can also prevent dusting and save labor while adapting eco-friendly concepts.

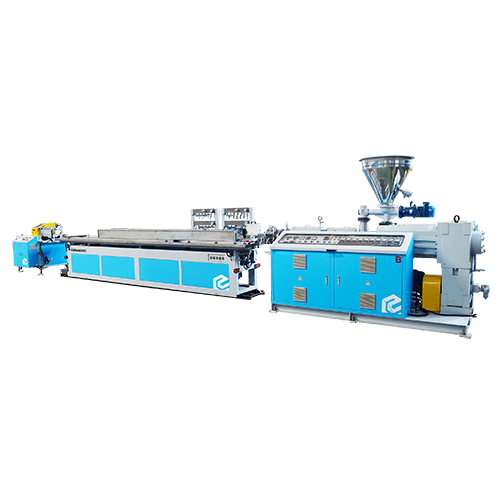

WPC押出生產線

產品分類 : 管材及異型材押出生產線

循環經濟是全球關注的議題,Everplast 也一直致力於此,其中WPC更是能有效的使用回收PE/PP塑料配合天然纖維,透過WPC押出生產線製造仿木產品,此WPC產品現今也活用在室外建材當中。 Everplast發塑木複合材料(WPC)的新性能,例如PP/PE樹脂混合40-80%天然纖維或PVC混合40-70%天然纖維,生產不同種類的WPC型材。 根據塑膠基材,WPC主要分為PVC、PE、PP、PS、ABS塑膠基底。 其中PVC/PE/PP塑木較受市場歡迎,具有木質感,可耐高溫。外觀和紋理與真木十分相似。

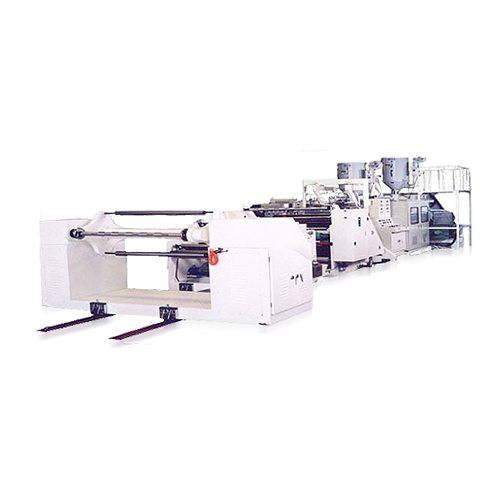

大型農業、地膜及工業用吹膜機

產品分類 : 吹膜押出機

The films is greatly helpful in agriculture and geomembrane. - Greenhouses that could increase the temperature to improve the growing environment and increase the available areas for planting, especially in high latitude and cold regions. - Mulch films could prevent the soil moist loss and preserve the temperature to keep soil warm that provide a suitable environment for seeds and sprout. - Silage films and stretch films is also more popular to store silage, hay and maize. - Geomembrane film could used to the construction for preventing leakage, water diversion for irrigation and reservoir and non-slip at side slope. Specification Layers: 3 / 5 layer Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. Opened film width range in 6 - 20 meters Designed output range 600 - 2000 kg/hr

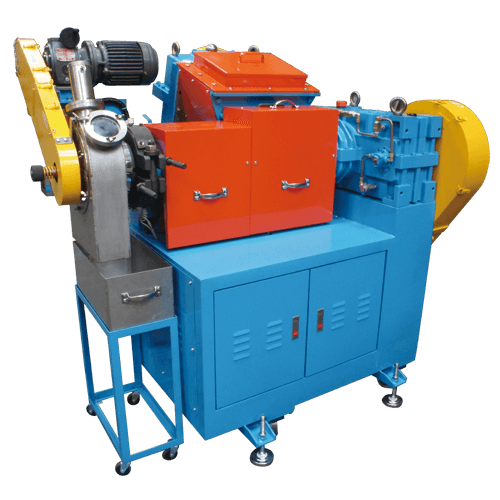

實驗型押出機 (PR50)

產品分類 : 製粒機

PR系列為雙錐供料與壓岀機結合的設計,適合用於密鍊機以及萬馬力機混練而成的團狀原料。雙錐供料設計,以前進推力擠壓原料,讓原料穩定入料,減少斷料以及少料的風險,提升產品良率,創造產品品質。強力而穩定的料體設計,為您創造一個穩定運行的生產線,運用獨特設計讓您放心生產,免除擔憂!

SP-420 / 60205

Especially for bulky plastic products. Eliminate the disadvantages of traditional high horse power crusher.Also for cracking unusual objects,waste tyres,logs,sleepers,etc. ● 2-shaft,claw-cutter breaker has the best ability to shred anything with low noise,vibration free. ● Auto reversible equipment to prolong the life of machine.

立式關模立式射出機-YH系列

產品分類 : 立式射出成型機

-四柱/垂直夾緊,垂直注射。 拉桿之間的矩形形狀,易於插入。 -雙注射氣缸平衡,實現平穩,強勁的注射。 -結構簡單,佔用很少。 -雙作用夾緊缸,用於快速夾緊,低速高壓夾緊。 -單次滑動將下模推出,便於裝卸。 -雙重滑動使用兩個下部模具,在操作員裝載另一個模具的同時對零件進行機加工,以提高生產率。