槳輪曝氣機浮子後冷卻裝置

產品分類 : 冷卻裝置

Our Customized Post Cooling unit helps to complete the formation of the Paddle Wheel Floats because: - It reduces the total cycle time of the floats. - Increases the production output for our customers. - Strengthens the float structure. - Helps to avoid the float to deform easily.

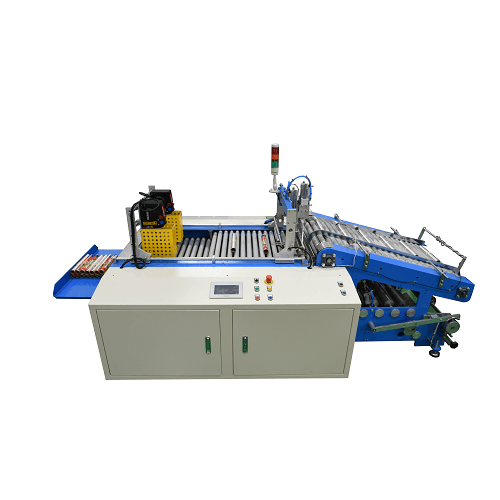

高精度自動裁切機(捲對捲) TRC-350GP

產品分類 : 發泡成型機

自動對邊張力控制系統: 針對捲材設計,可使收料控制更加穩定流暢。 優越且安定的下死點精度: 本機經特殊設計,及精密加工,裁切精度穩定度極高,成品良率可達百分之百。 裁切深度調整機構: 設定採參數輸入的方式,並有記憶模組,操作簡便易上手,可調全斷或半斷裁切,架模速度快。

PVC/TPO軟質製品押出機

淩鉞國際設計、規劃並提供各種PVC/TPO軟質製品押出生產線,適合各種PVC/TPO軟質製品的生產;例如PVC桌巾、浴廉、地磚底層、透明膠布、汽車裝飾墊、TPO桌巾、浴廉、印刷膠布等。押出機及壓延成型機是該生產線中的主要設備。2輥輪組成的壓延成型機是生產線的核心設備。基於目標產能及製品的要求,在選擇各押出機長徑比、壓延輥筒直徑、寬度、材質和技術配備方面。我們將竭儘全力為客戶提供最大效能的設備。我們的壓延成型機設備配置厚度調整系統。通過採用輥彎、中高等方式可以獲得最佳的製品厚度分佈,此外,這些裝置還可以配備電子裝置,以收集并自動調整所有的生產參數,確保加工工藝的控制。

AUTOMATIC SHRINK FILM PACKAGING MACHINE (TPG 50)

產品分類 : 分切機和複捲機

Model TPG50, the automatic shrink film packaging machine. A special design for wrap roll products. It can be connected to the back side of rewinding machine as an automatic production line. You can not only make your product refined and protected, but also arrange manpower more effectively. TPG50 is carried 3 conveyors as 3 work areas. It uses conveyors to deliver products to the processing area. You can choose automatic feeding of the material,or feed by detected sensor. As shrinkable films, BOPP, PVC and PE can be used on TPG50. The length of over wrapping film can be set manually or detected by the mark sensor. For packing decoration, you can use printed film; or, equip with a label paper device. The device will insert a piece of label before shrinking. The label will be wrapped inside the film, makes your product eye-catching. The last step, electrostatic device and thermal-wind will perfectly pack your products! Welcome to consult machine with us, we will at your service.

RAPID PROTOTYPING

產品分類 : 熱澆道系統

With the advent of 3D printing, rapid prototyping can now be done quickly and affordably. YOMURA TECHNOLOGIES is equipped with a high end, Digital Light Processor 3D printer built by Carima, a South Korean company with over 30 years of optical manufacturing experience. Unlike Fused Deposition Modeling (FDM) 3D printing which heats a plastic filament then squeezes it through a nozzle to print one layer at a time, DLP uses a special light wave to activate a chemical reaction in a photopolymer resin which then cures into solid 3D object. DLP objects are smoother, more detailed and almost seamless, ideal for professional quality prototypes. 3D PRINTER SPECS Max Build speed: 30mm/hr Resolution: 1920 x 1080 Size: 200 x 112 x 200mm 245 DPI High-end DLP (Digital Light Processing) 12 micron engine enables a very fine prototype Very minimal material waste MATERIALS Acryl: Easy post processing and coloring ABS-like: Semi ABS durability Epoxy: Great durability Rubber-like: Elastic material Lost-Wax: Metal Casting

齒輪聯軸器

產品分類 : 齒輪

(1) Crowned tooth allowed larger tolerance in shafts and higher loads. (2) Special hardening treatment W/high strength and anti-abrasiveness. (3) Closed type coupling--easy lubricate & anti dust as well as no leakage. (4) The type of TIEN YI GEAR SHAFTS COUPLINGS had been successful the first processing, it must be done the second procedure heat treating again according to material. And it were given them more rigidly precise, increasing stronger tenacity. At last removing gravitation by striking-ball bearing when those steps all finished.

高精度捲對捲自動送料裁斷機 TRC-350SP

產品分類 : 發泡成型機

裝軸同步送料機構: 雙軸同步送料提高了產出速度及良率。 優越且安定的下死點精度: 採用了矗霖特有之專利下死點機構,重複定位精度+\-0.005mm。 高精度深度調整機構: 採用高精度機構,微調精度可達0.01mm(0.001mm為選配)。 高效率增壓迴路: 較傳統迴路減少了30%以上之電力消耗。 光學材料對應: 可依照材料之特性做專用之搬送系統。 獨特的材料搬送機構: 高穩定性之伺服控制系統,不會汙染及刮傷材料。 自動潤滑機能: 全機採用自動潤滑機構,減少日常保養的工作。 廢料收捲機構: 裁斷加工後之廢料自動收捲,節省空間,提高作業性。