EPS 蒸氣熱注發泡杯系統

產品分類 : 發泡成型機

管型靜電油煙廢氣處理設備

工業型機種:適用於PVC壓延機、PVC發泡機、紡織業定型機、化工製程ABS、PS押出設備、金屬冶煉、螺絲生產線、玻璃窯爐、紙漿製程、焚化爐等排氣污染之工業所排出的油煙廢氣處理。

全電中空成型機 PK-e 系列

產品分類 : 押出中空成型機

單站/雙站 單頭/雙頭/三頭/四頭…8頭 生產範圍:2ml~35L 多層:1-6 層 多穴:1~8穴 專門用於PE/PP/PETG/PVC/尼龍/多層 材質 選購設備:刻度線 Clamping system:Ultra Locking System/Toggle/Tie Bar 驅動型式: 高效能全電伺服系統/油電伺服驅動系統/高效能循環系統/必迴路比例閥系統 支援: 全電/全油厚薄控制器/自動除溢料/自動回收/自動供料系統/遠端監控故障排除/模內貼

Hopper-Dryer

產品分類 : 乾燥機除濕機

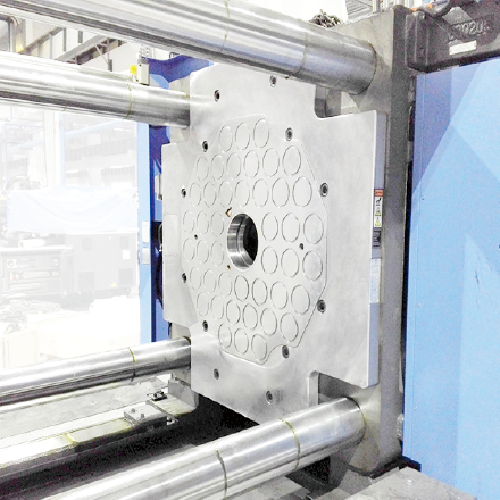

Tooling Shop

產品分類 : 熱澆道系統

TOOLINGS FOR OPTIMAL PERFORMANCE AND RELIABILITY The core of the injection molding process is the tooling. In regard to their design and manufacture, the high-end machinery used is absolutely essential. This is why Yomura introduced a state-of-the-art and fully-automated system works 24/7 to fabricate the toolings and makes no compromises with respect to quality – and conceives and produces high-precision, custom made fast cycling injection toolings in house. MANUFACTURING CAPABILITY Tooling Automatic Fabrication Key points: All Process and measurement data are connected to minimize men key in error. All work piece are implanted with RFID chip to minimize men error. Pre-set 2D and 3D are used before and after process to ensure the work piece are manufactured to the 100% accuracy. Productivity will be expected to increased at least 30 % monthly.

高精度捲對捲自動送料裁斷機 TRC-350SP

產品分類 : 發泡成型機

裝軸同步送料機構: 雙軸同步送料提高了產出速度及良率。 優越且安定的下死點精度: 採用了矗霖特有之專利下死點機構,重複定位精度+\-0.005mm。 高精度深度調整機構: 採用高精度機構,微調精度可達0.01mm(0.001mm為選配)。 高效率增壓迴路: 較傳統迴路減少了30%以上之電力消耗。 光學材料對應: 可依照材料之特性做專用之搬送系統。 獨特的材料搬送機構: 高穩定性之伺服控制系統,不會汙染及刮傷材料。 自動潤滑機能: 全機採用自動潤滑機構,減少日常保養的工作。 廢料收捲機構: 裁斷加工後之廢料自動收捲,節省空間,提高作業性。

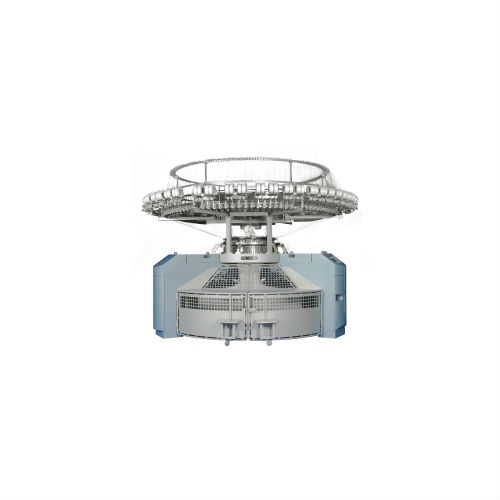

多層共擠吹膜機(JC-CX系列)

產品分類 : 共擠吹膜機

The JC-CX series Multi-layer Blown Film Line is available in two layer, three layer, and up to five layer configuration based on a modular concept producing variety of quality film over various industries. Combines high output with excellent film quality, the line is designed to produce films for a wide range of application. From general purpose packing film or lamination film, of complex technical film or food packaging with high grade barrier properties, JC-CX series blown film line has convincing solution to every customer’s need.

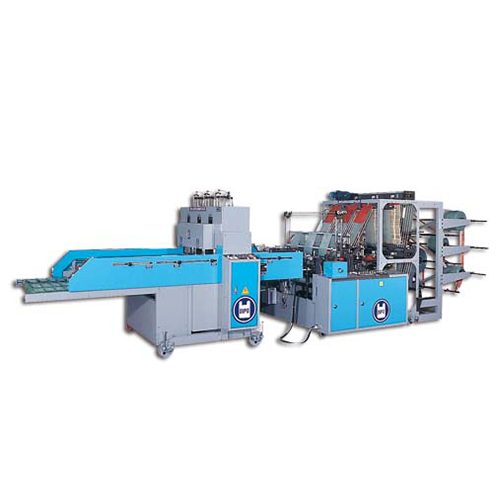

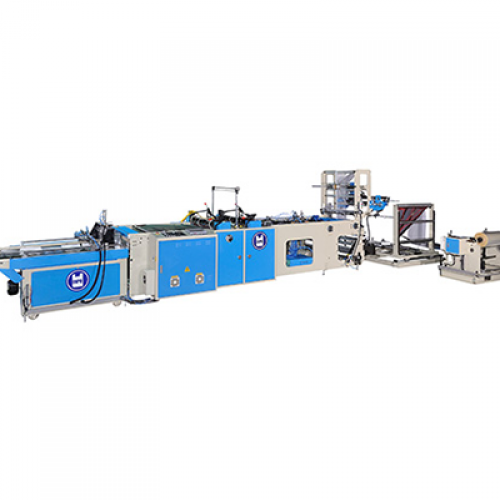

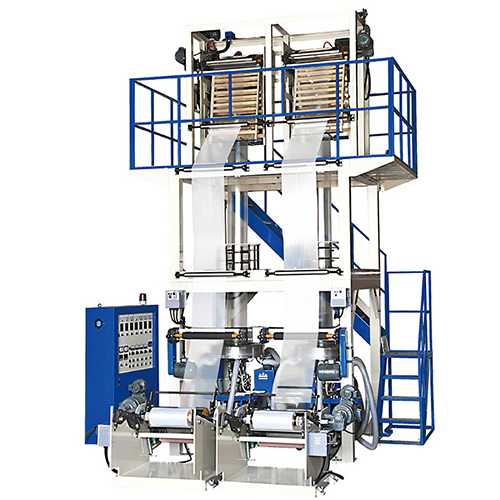

高速單層膜雙膜頭吹袋機

產品分類 : 吹膜押出機

This two-head blown film machine line can produce 2 film rolls of the same width at the same time, and the production capacity is thus comparatively higher than models with only one die head. Thanks to the twin-head design, it not only occupies less space but also consumes less energy, which offers an economical solution for producing plastic bags of smaller width.

HDPE A級 / 本色

產品分類 : HDPE樹脂

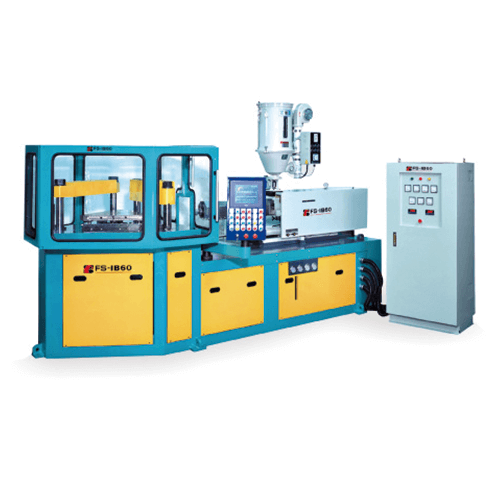

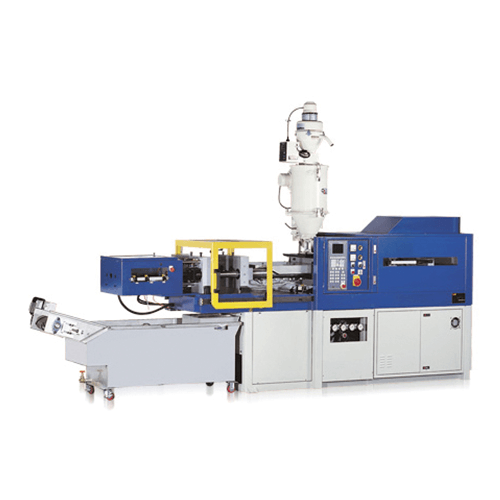

一步法射出吹氣成型機-FS-IB60

產品分類 : 射出中空成型機

鍑鑫一步法射吹機是高速精密的先進機械,結合射出成型機和延伸吹氣成型機的概念而研發製造。 將兩種不同機型的特色及優點結合在一起,是一機多功能之先端科技產品,提供客戶更多樣化選擇。

自動進針鞋跟機

產品分類 : 油壓夾模式射出成型機

● Rapid, high-precision direct hydraulic clamping system. Automatic needle loading, multistage ejection setting. ● Two adjustable nozzles with hot runners, molding 2 heels without runner in one shot.

多層拉伸套膜吹膜機

產品分類 : 吹膜押出機

People replace stretch wrap film with stretch hood film. The stretch hood film has excellent holding force and extraordinary elasticity, so that it could cover the cargo tightly and prevent the stacked sacks from collapsing. It improves the security in logistic transportation greatly. Furthermore, it has high puncture resistance to protect the goods and provides good transparency that assist people to distinguish the content of cargo and to scan the labels. Specification Layers: 3 / 5 layer Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. Film width: 1500 ~ 1850 mm Output: 280 ~ 450 kg/hr

尼龍 6 工程塑膠 - NA1200GK35

產品分類 : PA樹脂/尼龍

玻璃纖維增強35%,高模量,高衝擊。 應用說明:手工具、電動工具、園藝工具用,汽車、機車、腳踏車零組件用,運動器材零組件用,電子、電器外殼及零組件用,O.A.辦公室零組件用,水資材用,醫療復健器材。

GT (伺服驅動機型)

產品分類 : 凹版印刷機

GT (伺服驅動機型) 高度自動化的機台在每座色座上都配有伺服馬達。機台在設計上結合了凹版印刷的品質與快速換工作的功能,操作起來簡單,將資源浪費減到最低。若您正在尋求一台伺服驅動的凹版機台,您可參考此印刷機來客製。

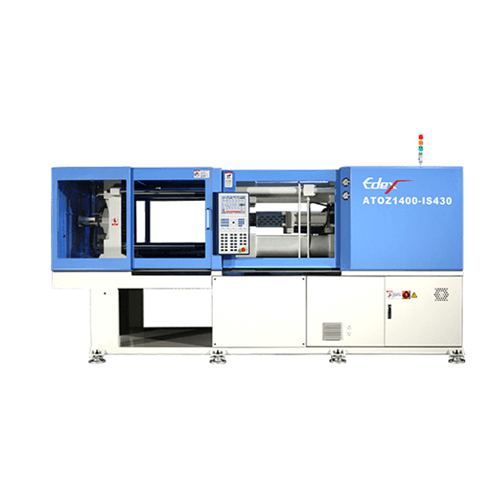

ATOZ系列 精密螺桿式射出機

產品分類 : 臥式射出成型機

Stack Type Flexographic Printing Press

產品分類 : 膠板印刷機

他的RPM系列柔性印刷機將性能和經濟價值結合在一起,為我們的客戶提供服務。感謝我們的人機工程學,用戶友好的沖壓設計,使機器操作變得簡單而簡單。工作變動不再是一項繁重的任務,減少了停機時間,並增加了利潤。

INSERT INJECTION MOLD

產品分類 : 射出模具

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

連續式(真空充氮)封盒包裝機

產品分類 : 中空包裝機

兆酆連續式真空充氮封盒包裝機為不銹鋼材質製造,真空室外安全蓋設計,開啟電器箱即斷電,安全性高,可一機多組不同規格模具使用,模具更換容易,多國語言且擺臂活動式的PLC人機觸控,方便360度操作,螢幕所有功能為文字敘述,方便操作者了解使用。真空 / 充氮、真空 / Skin Pack、封口包裝。且提供各式機器尺寸,以應不同大小尺寸的包裝盒需求。