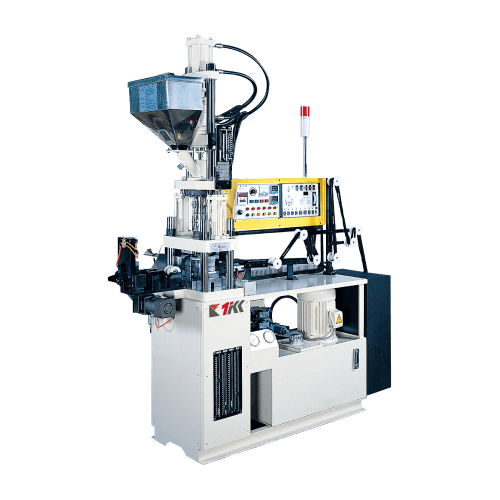

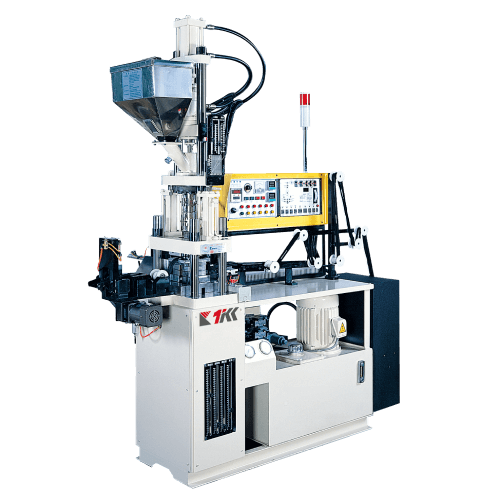

KC Series Vertical Injection Molding Machine (標準型)

產品分類 : 立式射出成型機

立式鎖模,臥式射出,無機柱設計,三面開放空間,適用於中型埋入件射出成型.....

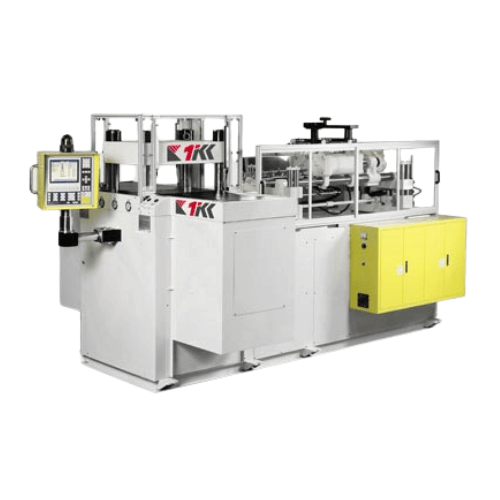

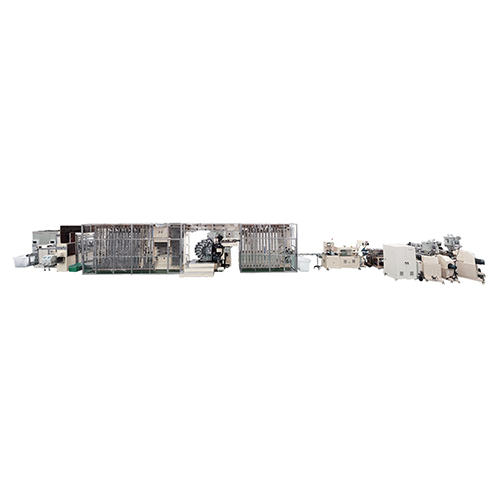

半自動轉印機器 YHT-222A2XF

產品分類 : 水轉印機

浸漬槽+自動覆膜+自動噴塗系統 浸漬槽 2 米長。 WTP 處理所需的所有重要流程的強大組合。 從最開始的鋪設,隨後的活化劑噴塗到最後的浸漬階段,只需一個按鈕即可完成主要的 WTP 過程。 本機包括浸漬槽、自動覆膜和自動噴塗系統。 這三個組成部分的結合不僅使 WTP 變得更加簡單,而且更重要的是——最終產品的質量穩定。 系統可以記憶多組不同的過程。 這台浸膠機非常適合大產品和中等產量/天。

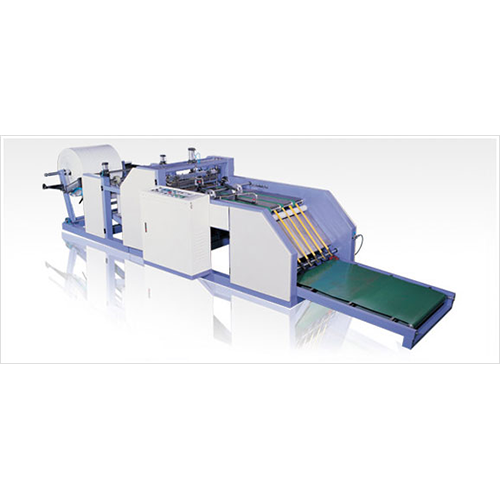

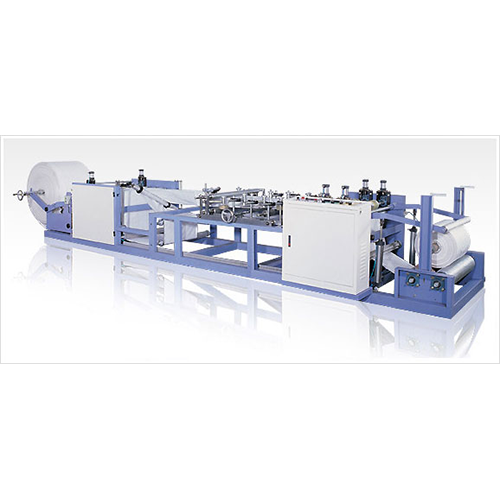

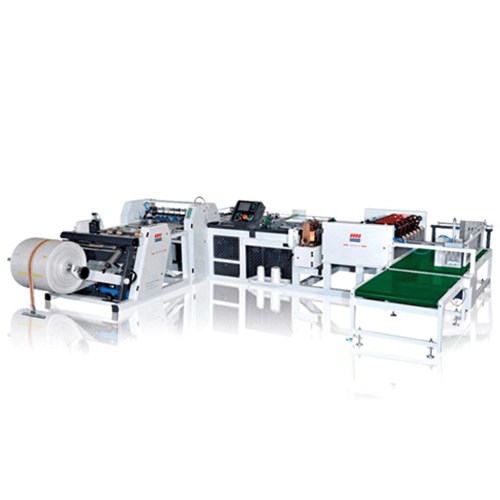

Gusset-Cutting And Sewing Machine For Gusset Bag

產品分類 : 切割機

● Un-winding unit equipped with EPC ● Micro-Perforation unit ● Gusset Forming unit (equipped Infrared Rays for forming quality) ● Mark sensor for printed fabric roll ● Cutting unit equipped both cold cutter and hear cutter ● Bottom fold & sewing unit ● Finished bag automatic count stacker delivery unit ● Print Output : 32-48 bags / minute

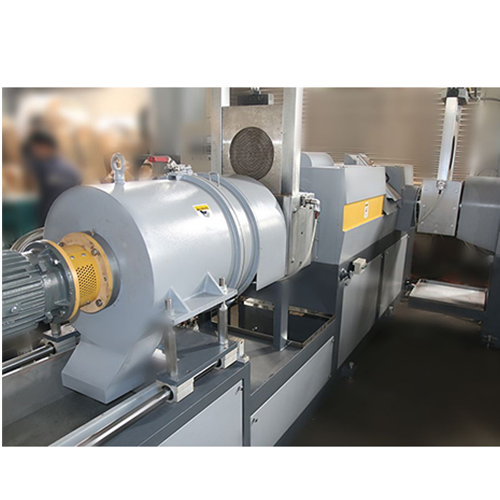

成功案例 - 強押側邊入料塑膠回收造粒機

產品分類 : 廢塑料再生機

RECO-Z-125i / 強押側邊入料塑膠回收造粒機 / 水洗PE薄膜 / 台灣 RECO-Y-150i / 強押側入料塑膠回收造粒機 / HDPE 瓶片 / 台灣

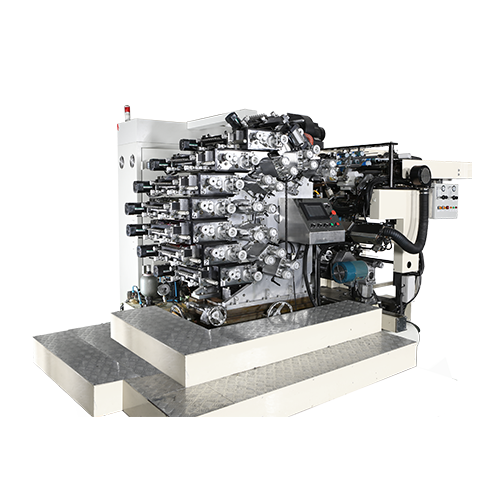

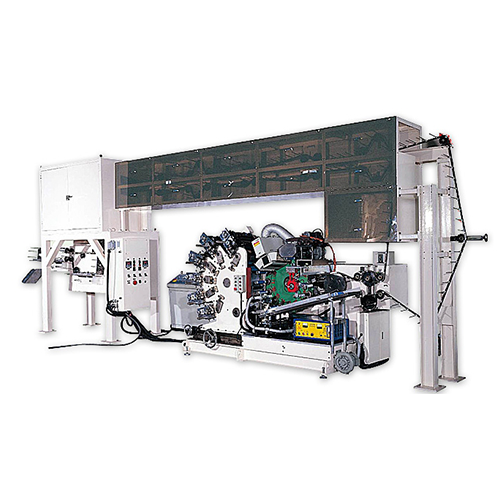

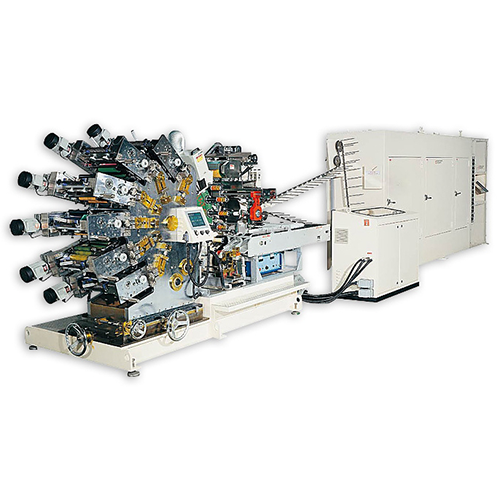

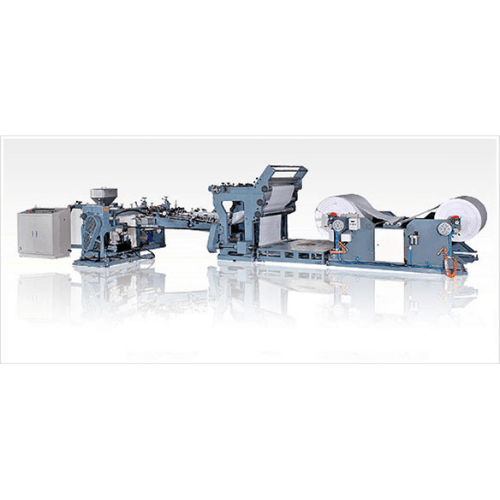

膠版印刷機PKF-8 系列

產品分類 : 膠板印刷機

● Machine framed with 50MM cast metal plate, provide a very steady, vibration free foundation for the printing work. ● All gears are helical design. ● AC main motor from Siemens and controlled by Japan made inverter to provide a steady speed performance. ● Inking rubber rollers are driven by European made hydraulic motor independently, speed can be adjusted for controlling ink transfer volume. ● Simple but accuracy and steady vertical and horizontal image adjustment device. ● Long arch type drying tunnel with high capacity blower, to allow ink quick drying during high speed operation. ● Bearing house design for holding rubber roller, plate cylinder and anilox roller. ● Machine can be equipped with Japan auto tension controlling system, close chamber doctor blade, EPC at unwind, rewind as optional choice. Flexo Stack printing Machine Flexographic printing machine CI Flexoprinting Machine Flexographic Printing Machine FLEXOGRAPHIC PRINTING MACHINE FLEXO PRINTING MACHINE FLEXO STACK PRESS FLEXO PRINTING PRESS CI PRINTING PRESS CI PRINTING MACHINE PAPER PRINTING MACHINE PAPER PREPRINT PRINTING MACHINE OFF LINE PRINTING MACHINE

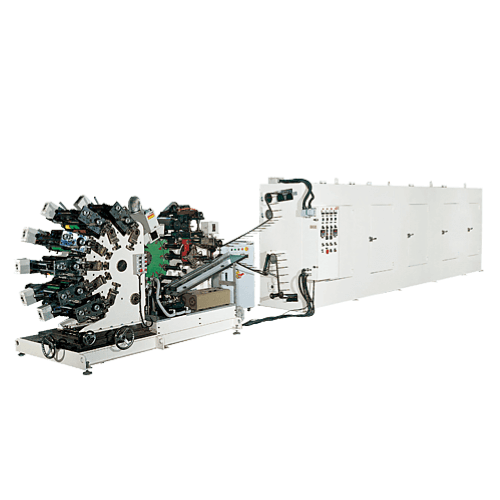

膠版印刷機 PKF-4 系列 / PKF-6 系列

產品分類 : 膠板印刷機

.50MM厚度車壁提供各印刷座穩定及無振動的基礎 .所有齒輪均為斜齒設計 .以日系變頻器控制歐系交流馬達, 使機械速度穩定順暢

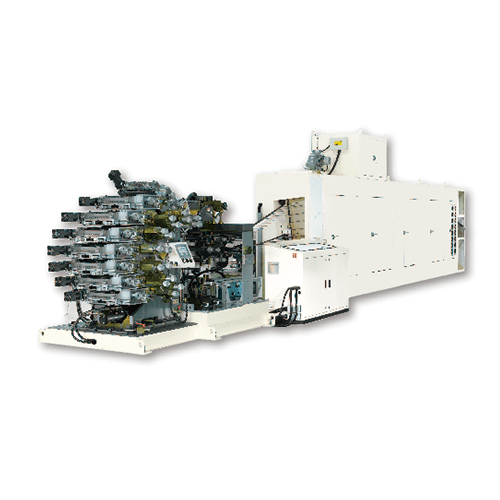

高速膠版印刷機(含網路遠端診斷功能) PKF-6HS 系列

產品分類 : 膠板印刷機

本機提供大輪式印刷機外另一個優勢選擇,可提供高精準印刷表現同時亦提供方便的正/ 反面印刷功能。採用大型齒輪直接傳動各印刷座,穩定的齒輪傳動使本機可高精準印刷表現。

全電腦6色印刷機、上光與烘箱PCD-80-06-RE

產品分類 : 燙金機

Precise index ensures accuracy of every movement. It is easy to disassemble the printing mandrel. Tube feeding system works with detector. Coating mechanism will not move. Without tubes on mandrels. Equipped with precipitator. Corona system can keep tube clean before printing. With optional sleeve printing mechanism. Tubes are headed directly after printing. No double-heading or double cutting procedures and save material. Vastly used on printing different shape of tubes.

自動連線轉接控制系統

產品分類 : 押出塗佈機

Automatically storage functions. Available to connect with outer diameter control unit, to separate / remove defect tube via conveyor, not into accumulator. Automatically separate / remove tubes when accumulator fully loading. Automatically transfer tubes to printing machine and heading machine.

全電腦8色印刷機、上光與烘箱PCD-80-08H-RE(UV)

產品分類 : 押出塗佈機

Double transferring rollers design. Stopless roller adjustment design. Plate wheel outer finetune mechanism Quick release ink rollers. Printing wheel clean system (200 mm dischargeable) Sleeve Printing Plate wheel pre-register mechanisim.

全電腦6色印刷機、上光與左側烘箱 PCD-80-06-UV-L

產品分類 : 押出塗佈機

-烘箱放置左側,排管人員不受空間的限制,方便排管,以利日後連缐作業或者可將生産缐一字排列。 -軟管退管方式,採用自動提出方式,可減少使用氣壓退管時的噪音。 -本機增加無肩印刷的功能,可與一般正常印刷功能互換,一機二用,減少成本。

全電腦6色印刷機、上光與烘箱PCD-80-06-UV

產品分類 : 押出塗佈機

For UV lacquer, special UV oven is required, which is equipped with rapid drying mechanism to produce tubes with glossier surface. We also offer UV & heater oven, which can save electricity and without space-limit. Customers can choose either of them accordingly. Precise index ensures accuracy of every movement. Tube feeding system works with detector. Coating mechanism will not move without tubes on mandrels.

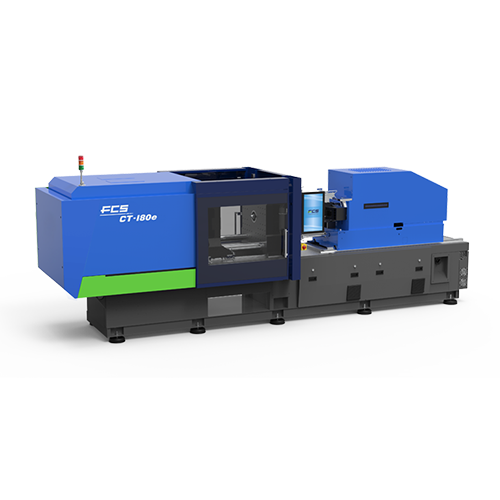

車門相關零件

本產品採用PP+GF(玻璃纖維增強聚丙烯)材質,具備高強度、耐衝擊、耐熱性與低變形率,確保大板與主板在高負載環境下依然穩定耐用。適用於結構支撐、工業設備、汽車內外部零件等應用,提供卓越的機械性能與長期穩定性。 本產品由1600 噸大型射出機成型製造,可生產大尺寸、高精度的塑膠零件,確保結構剛性與一致性,滿足各類大型零件需求。此外,相較於金屬零件,PP+GF 兼具高強度與輕量化特性,有效減輕產品負擔。

成功案例 - 三機一體塑膠回收造粒機

產品分類 : 廢塑料再生機

KRIEGER-85 / 三機一體塑膠回收造粒機 / LDPE薄膜 / 美國 KRIEGER-125 / 三機一體塑膠回收造粒機 / LDPE及HDPE薄膜 / 印尼 KRIEGER-100 / 三機一體塑膠回收造粒機 / PE薄膜 / 越南 KRIEGER-Z-125i / 三機一體塑膠回收造粒機 / PE發泡 / 韓國 台灣PE回收大廠合作 長毅營運倍增,追加投資3條新產線 KRIEGER-150 / 三機一體塑膠回收造粒機 / BOPP薄膜 / 韓國

PP編織袋自動切縫機CS-2002 / 1-4顏色

產品分類 : 切割機

● Zigzag Type High Quality Alloy Steel Cutter ● Double-Fold sewing Guide Device ● Cold Cutting System (for laminated bag) ● Mark reading sensor (for pre-printed fabric roll) ● In-Line Gusset Device ● Perforation Needle Roller

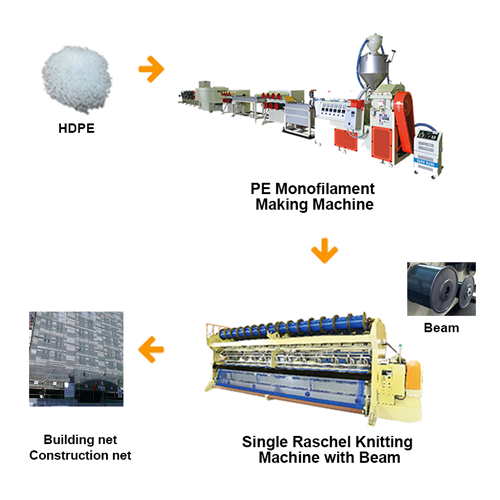

建築防塵網

產品分類 : 工業針織機

This extrusion line is designed for making monofilament and suites for PE raw material. It can offer the round yarn (monofilament) to model SR-R & DR-R knitting machine. Model SR-R series is Single needle bed Raschel knitting machine which design for making the Round yarn (mono yarn) in all different kind of raw material, for example Nylon, PE, PP etc.

Semi-Automatic Bag Sewing Machine

產品分類 : 切割機

● Multi-purpose For Laminated PP Woven Bag, Un-laminated PP Woven Bag, Kraft Paper Bag ● Equipped Sewing Thread Broken Sensor ● Equipped Auto-scissor For Thread Cutting ● Finished Bad Auto-counting & Stack

Reel to Reel Gusset Line TRG-700

產品分類 : 塑膠袋製袋機

● Reel to Reel line designed, easy for operation ● Equipped twist device for turn printing position to the central of gusset area

Jumbo Bag Cutting Machine

產品分類 : 切割機

● Equipped Servo Motor for precise cutting length (±1%). ● Equipped high quality alloy steel cutter. ● Equipped bag mouth open device. ● Punching Unit for "X" Hole and "O" hole Punch available. ● Custom-made designs are available.

PP編織袋自動切縫機CS-2012

產品分類 : 切割機

• Equipped Two Servo Motors • Equipped 90゚Bag Transfer Gripper • Display Screen Operation Interface • High Product Output (32-45 Bag / min) • Custom-made designs are available

Automatic PP Woven Fabric Tubing Machine

產品分類 : 編織袋製袋機

General Performance: a. Diameter of Unwinding Cloth: 1000 mm Maximum b. Processing Flat Fabric Width: 640 - 1350 mm c. Production Output: Max. 100 Meter / Minute