Vacuum Packaging Machine (GD900)

產品分類 : 中空包裝機

Power:AC220V3Φ Machine Size:1020x740x1080/mm Chamber Size:960x620x180/mm Sealing length:900mmx2

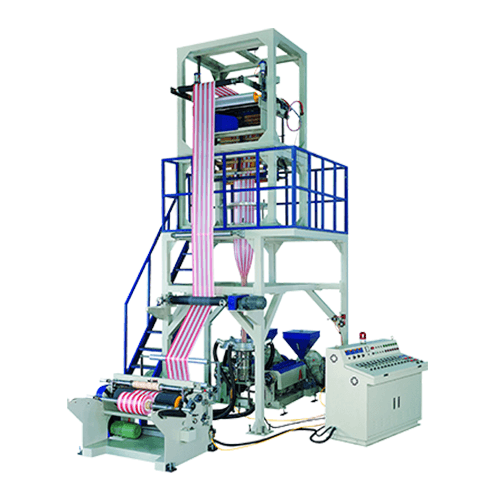

大型農業、地膜及工業用吹膜機

產品分類 : 吹膜押出機

The films is greatly helpful in agriculture and geomembrane. - Greenhouses that could increase the temperature to improve the growing environment and increase the available areas for planting, especially in high latitude and cold regions. - Mulch films could prevent the soil moist loss and preserve the temperature to keep soil warm that provide a suitable environment for seeds and sprout. - Silage films and stretch films is also more popular to store silage, hay and maize. - Geomembrane film could used to the construction for preventing leakage, water diversion for irrigation and reservoir and non-slip at side slope. Specification Layers: 3 / 5 layer Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. Opened film width range in 6 - 20 meters Designed output range 600 - 2000 kg/hr

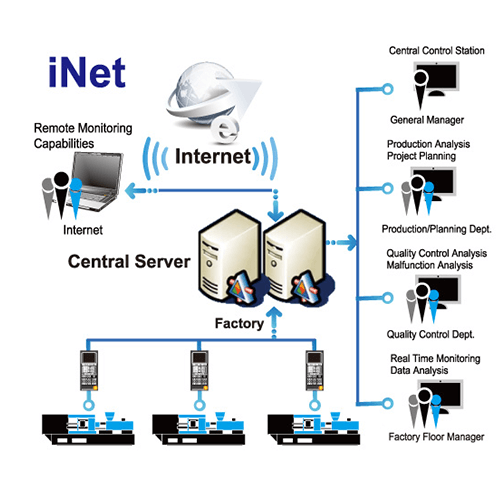

軟件產品及服務系統-iNET

產品分類 : 控制設備

iNet是一套完整的射出機工廠網絡化管理解決方案,協助塑膠廠生產與車間管理,藉由網路連結,作為管理層與生産現場溝通的橋樑;亦使管理者(administrator)進行全球營運,提供客戶管理新趨勢、掌控世界潮流,是成功邁向企業資訊化的必備武器。

2RT開模輪胎膠囊專用橡膠後射式成型機

產品分類 : 橡膠射出成型機

2RT超越了傳統的頂部開模,可用於雙模或三模,並具有開模的設計並在兩者之間推出模具。可以通過軟件調整開模,並分別打開,分開推開模具,連續打開和連續推開模具。

INSERT INJECTION MOLD

產品分類 : 射出模具

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

全自動伺服四線蔬菜製袋機

產品分類 : 塑膠袋製袋機

壓切式氣動刀架 S-100/120 系列

產品分類 : 工業用刀具

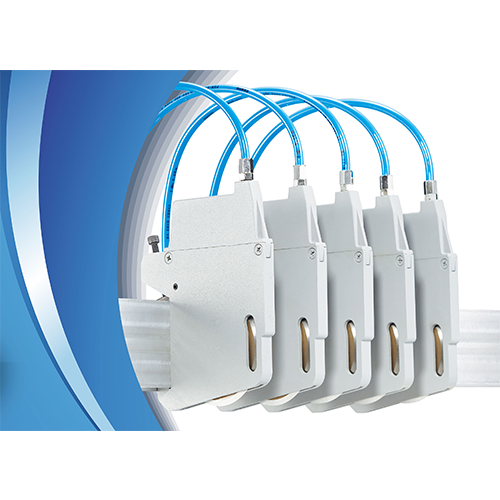

MPT 微電腦溫控制器系列(高階型)

產品分類 : 控制設備

同時具有MPR型及MPE型各項特點。 具有單片面板同時多段溫度控制,幫助客戶節省體積與成本。 通過通訊阜,可人機介面設定流程,檔案儲存。 具有檢測Module漏電、FUSE開路故障警報。 具多種保護功能設計,能避免各種人為疏失所造成感溫線、加熱器及溫控面板損壞

全自動補丁手柄/循環處理/聚抽獎處理 /模切處理製袋機 SPH系列

產品分類 : 塑膠袋製袋機

●型號:SPH-321S●速度(循環/分鐘):30-80●寬度(mm):250-600●長度(mm):250-600生產各種手柄袋,模切手柄袋,拉帶袋和貼片手柄袋。

三層共擠FFS重包裝吹膜機

產品分類 : 吹膜押出機

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.

PP Woven Bag Related Machinery - JLRGSM-SERIES

Simple Operation Good accuracy Vertical type design

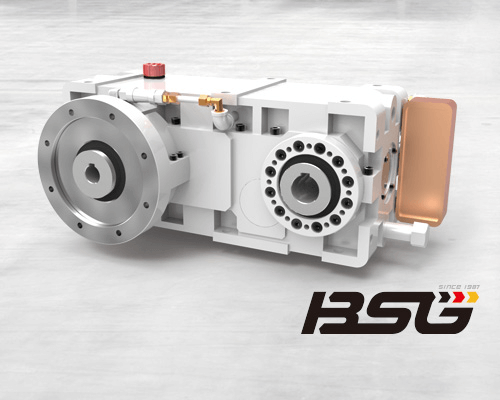

Direct Drive Gearbox

產品分類 : 齒輪

自動高速包裝機 - SFA-SD30

產品分類 : 中空包裝機

人機螢幕操作。 自動顯示訊息錯誤,以利故障排除、維修。 包裝產品適應各種馬口鐵罐、鋁罐、PVC瓶、PET瓶、玻璃瓶不同類型。 螢幕上可設定及修改機器內部參數。 機械調整上皆有卡尺標示以便紀錄,方便調整。 更換模具時間短,適用各種尺寸。 本機台活動部分均有油嘴可以潤滑,底部不方便進入之軸承均裝置油管在外集中潤滑。

同向雙螺桿押出機齒輪箱

產品分類 : 齒輪箱

高精度小尺寸自動裁斷生產線-APL-300

產品分類 : 發泡成型機

●伺服裁斷機構: 裁斷主軸採用伺服馬達控制,高效率,高精度。 ●自動送料機構: 採用高階伺服控制,送料速度快,定位精準。 ●與多軸自動貼合機連線: 與RAL-400高精度多軸自動貼合機連線作同步加工。 ●與自動切片機連線: 與AC-300小尺寸切片機連線作切片加工。 ●二次加工對應: 可對應雙站對位裁斷加工。