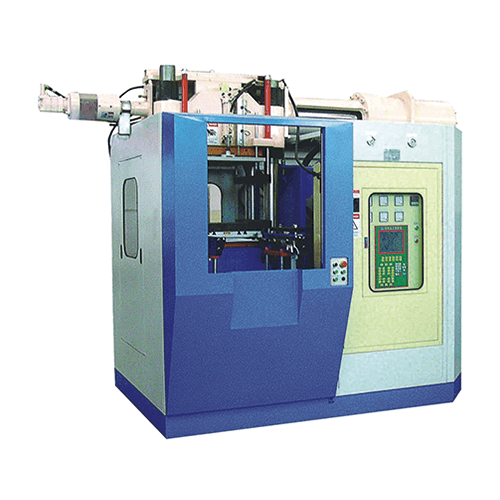

LIM、LSR立式矽膠機(轉盤/滑模)

產品分類 : 矽膠射出成型機

● Precision vertical clamping system (parallelism/ flatness : 0.02/100mm) , heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life. ● Increased productivity and efficiency with shuttle table or rotary table configuration. Pick and place products while another product finsihes molding.

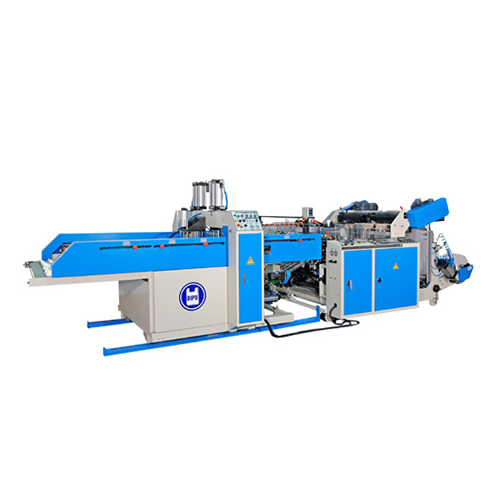

全自動高速四線T卹製袋機

產品分類 : 塑膠袋製袋機

編織繩包覆機&異型押出兩用機

產品分類 : 管材及異型材押出生產線

CE認證橡膠射出成型機 IRH(CE type)

產品分類 : 雨靴注塑機

Material supply system A special design of two-stage material supply is adopted. It expels bubbles out of the raw material in the most effective way and there is no dead material.

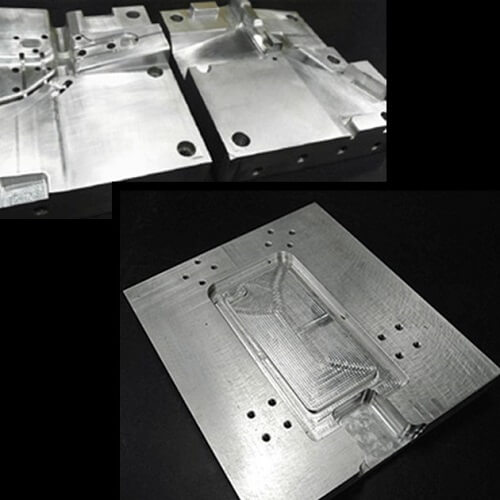

SOFT TOOLING

產品分類 : 熱澆道系統

For small production runs or for prototyping, soft tooling is a fast and low cost way to build multiple copies of your product. To provide quick mold soft tooling services our engineers were sent to Japan to learn from soft tooling experts. MATERIALS: Cavity & Core Insert Made from Aluminum or Steel, Mold base free ADVANTAGES: Low Cost & Short Lead Time (5-10 days) Useful for R/D testing and trail runs, reduces final tooling risks Can product approximately 500 Shots DISADVANTAGES: Soft tooling will cycle slower due to poor thermal conductivity of mold material. Material life of soft tooling is limited and will depend upon part complexity. Our mold fabrication shop is equipment with high-end Charmilles EDM and OKK CNC machines. Please visit our Mold Fabrication page for more details.

高速精密立式射出成型機-YQ系列

產品分類 : 立式射出成型機

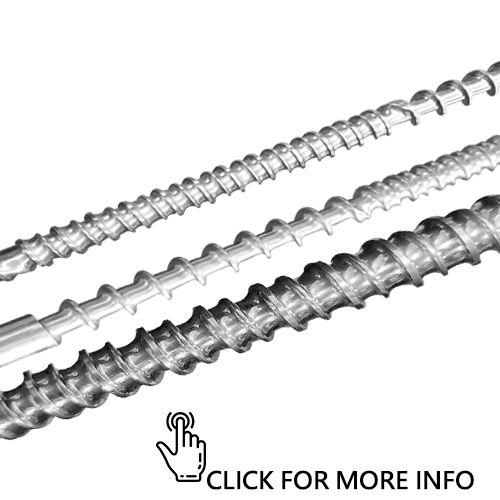

• Vertical four-pillar vertical clamping, with vertical injection. • The square pillar design comes with large mold size. The space within the column allows customers to install devices of automatic embedding and removing products. This allows automation for the whole machinery. • Big L / D ratio of screw, plasticizing evenly, suitable for injection molding of engineering plastics. • High standard computer control system with high precision injection pressure and high response injection speed. The quality is more stable for high-precision embedded injection molding products. • 1S single sliding: After mold opening, the lower mold will automatically slip in front of the operator for facilitating embedded molding operation. • 2S double sliding (Alternating double sliding): One mold for injection molding, another mold for taking out and putting on embedded parts operation. • 2SL double sliding (90°Alternating double sliding): One operator can operate independently. One mold for injection molding, another mold for material taking and putting on embedded parts. The two slidings are intersecting at 90 degrees, which can lower the production cost, and enhance the performance. • Able to combine automation and the high-speed injection can effectively enhance the production capacity. • A variety of circuit design (half closed servo hydraulic or high speed injection) to meet the customer’s requirements.

OVER INJECTION MOLD

產品分類 : 射出模具

Over Molding is the process where one material is precision molded over another material, usually rubber (TPE) over plastic, for visual or ergonomic appeal. Very often when the design requires ” soft touch” or waterproofing (IP68), over molding is the manufacturing process that we will use. For over molding success, knowledge of material compatibility is crucial. Our extensive expertise in this field helps assure your end part will have the strong end-application bond and performance that your product success demands. Insert molding can also be combined with over molding using parts made of aluminum, brass, stainless steel, copper, plastic and more.

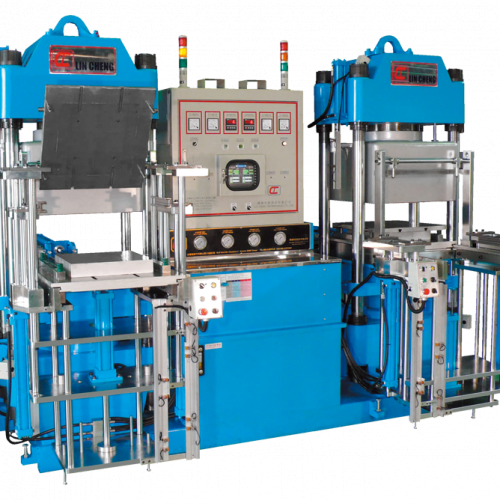

3RT 開模橡矽膠真空熱壓成型機 VCC-D3

產品分類 : 雨靴注塑機

●3RT架構特點在於超越一般傳統的頂式掀模,可用於三層或四層模具之特殊功能,具有掀模及中層模具個別頂出之設計 ●此掀模功能具有分段掀模、分段中模頂出、連續掀模及中模頂出之軟體設計,可依操作需要做調整。

後段外包裝設備 - 貼標機 - ABL-M

產品分類 : 標籤機

此貼標設備採用上糊式貼標方式, 設備動作採用全機械式,確保設備動作穩定性, 當產品尺寸變更時,只需更換部分零件與簡易調整即可完成不同產品應用。

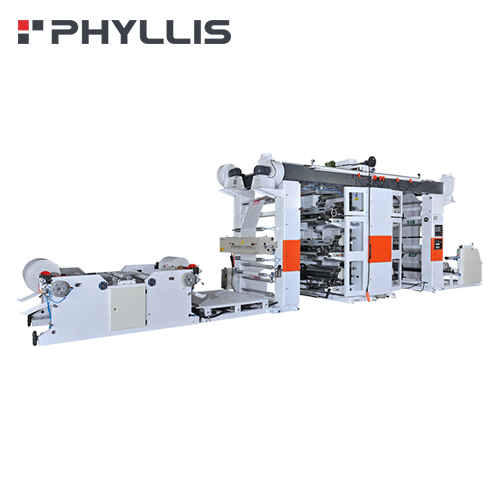

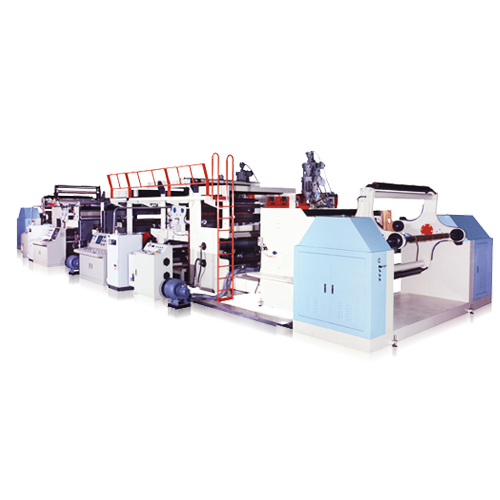

雙面雙層共擠壓複合淋膜機

產品分類 : 淋膜機

主機壓出量:350 Kgs x 2 Sets = 700 Kgs/Hour 副機壓出量:150 Kgs x 2 Sets = 300 Kgs/Hour 線速:40-220 Meters/Minute 淋膜寬度:600MM~1600MM

五層共擠吹膜機

產品分類 : 共擠吹膜機

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.