PET吹瓶機 LM系列

產品分類 : 全自動中空成型機

全自動PET吹瓶機LM系列配合高速精密吹瓶閥,將空氣回收轉換為壓力操作將減少空氣消耗。從料斗轉移到解擾器的瓶胚,按順序自動輸送到單個通道。縮短加熱間距以減少能量浪費並提高加熱效率。全自動PET吹瓶機LM系列採用連續集中加熱方式,冷卻坡道和吹氣裝置,有效地隔離了瓶胚頸部,避免了瓶胚頸部因過熱而變形。

PET吹瓶機系列-TEM0S82

產品分類 : 全自動中空成型機

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET吹瓶機系列-TEM08S2-88

產品分類 : 全自動中空成型機

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

熔噴模具

產品分類 : 押出模頭

SUITABLE AVAILABLE FOR POLYMERS INCLUDING PET And PP High processing precision. Internal heating with heating rod, external heating with heating board, temperature control by heating oil cycle to ensure products of good uniformity. Meltblown filter in continuous and automated production to cut production losses more than 35%, cu costs, reliable product quality. Cut production materials consumption sharply. Featuring high yield, low power consumption, low loss, easy operation. Integrated meltblown Extrusion Die. Integrated meltblown Extrusion Die featuring precision aperture, good consistency and without maintenance wear out. Improved meltblown fiber quality and uniformity, improved product quality. Improved Extrusion Die life cycle and life span. Reduced Extrusion Die change operating time, cut maintenance cost and power consumption. Installation capacity down 30 ~ 40 KW. Cut production costs sharply.

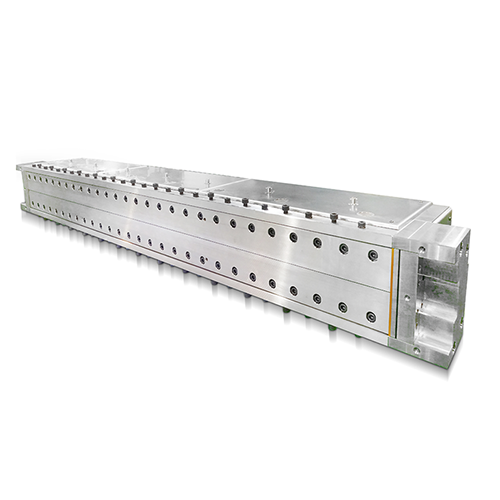

大型曲肘式伺服節能射出成型機

產品分類 : 臥式射出成型機

• 超大的柱內距與容模量,固定板和活動板採有限元素法(Finite Element Analysis) 分析設計,以確保機械的強度及剛性。 • 採用雙射移油缸可達到正確的模具對心效果,並可確保於高速高壓射出時射嘴不會漏料。 • 線性滑軌射膠系統,減低機械耗損及背壓產生,使產品射出更為精確。 • 採用BOSCH快速比例壓力速度閥,此閥本身帶有位置反饋,以及加裝壓力傳感器,使得控制器所下達指令能夠迅速反應回饋,達到敏捷精準的控制需求。

高精度油壓截斷沖床機 CSS-607

產品分類 : 發泡成型機

機身結構使用特殊鋼料造型、耐衝壓、永保平面度、衝頭與滑塊一體成型、高耐磨、強度特性、沖壓穩定、延長刀模壽命、刀具可使用雷射刀、沖床沖模均可、產品無鬚邊、各角度鮮明。 吹料裝置更可配合機械動作,一衝一吹,把斬後成品自動吹上,取料更方便、安全,加上萬能溝底盤;鎖模方便、迅速。並配置定點式腳踏開關等等,皆是展現高度成熟、專業工業設計取向。 半自動刀模設定,操作易上手,又安全。

高精度四柱式油壓裁斷機 CSS-603 (可裁半斷 & 0.01mm 精密度)

產品分類 : 切割機

本機由壓系統採用先進而耐用的特殊回路以及穩定性高的電控系統,可達超水準的效能。 上下沖壓行程由四大鋼柱代替滑軌,前後送料採用精密線性軌道。 機械啟動後,低噪音、動作敏捷、輕巧,利於樓層廠房設計。 有高度精度的裁斬深淺(微調)刻畫調整器,精度容許值0.008mm。 特殊平面鋼板,代替傳統式鉆板,永久不磨損,刀具使用壽命長,永保銳利,提高工作效率。 加工物件可全斷及半斷,背膠式物件亦可使用,產品無鬚邊。 可選購加裝自動冷卻系統及全自動裁斷深淺裝置。 本機有安全防護裝置,可確保人機安全。 高精度的機體結構,可作全斷及半斷加工。 上下沖壓行程採用四柱高剛性導柱,送料機構採用線性軌道。 兩斷式壓力控制,動作輕巧,低噪音,適合樓層廠房使用。 自動調刀機構,依設定自動調整,精度0.01mm(選配0.001mm)。 高精度德國鋼版,耐用度高,永不磨損。 本機採用先進且耐用的油壓系統及電控迴路。 安全防護裝置,確保人員安全(可選配CE架構)。

高速曲肘式伺服節能射出成型機 (TSV 系列)

產品分類 : 油壓夾模式射出成型機

• 特快鎖模系統,採用油壓差動迴路,提高速度達60﹪以上,縮短週期,節省能源。 • 特殊無給油自潤模板滑片,耐磨耐壓,耐用性久。 • 自潤銅司曲肘機構,確保機器之精度,可防止曲肘磨損。 • 採用BOSCH快速比例壓力速度閥,此閥帶有位置反饋,能夠迅速反應回饋,達到敏捷精準的控制需求。 • 適用成型精密度高、薄殼成品之塑膠製品。(成品厚度1 ㎜ L/t大於200) • 蓄壓器為選配裝置。