高速單層膜吹袋機

產品分類 : 吹膜押出機

先進的螺桿設計和槽式給料機,材料混合比例良好,產量高,生產質量可靠。 獨特的模頭和風環吹出穩定氣泡,並產出更均勻的膜厚和更均勻的袋子。為T恤包,購物袋,農業等許多方面提供了一個很好的解決方案。 機器高度可調整。 特性 原料應用:HDPE / LDPE / LLDPE / EVA 高效率機器,能耗低但產量高。 高級齒輪箱帶強制潤滑系統和油冷卻器。 螺桿和料桶的混合性能好。 選配裝置 自動進料機 單層膜模頭與風環 A/A雙層膜模頭與風環 旋轉模頭 手動換網裝置 IBC (氣泡內部冷卻裝置) OBC 膜厚控制系統 Corona 表面處理機 壓花輪 雙收台 荷重元 連線柔版印刷機

PP薄膜吹袋機

產品分類 : 吹膜押出機

High Speed PP Blown Film Machine is suitable for producing PP bags and films. Special design of screw results in better mixing to ensure high output and good film quality. AC inverter control motor for energy saving. The water-quenched system effectively makes films glossier and more transparent, very suitable for food, flower and garment packaging. Also capable of producing multilayer films (Model: CTPP)

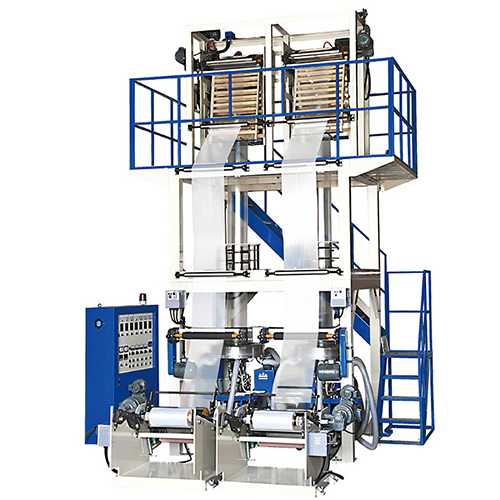

ABA吹膜生產線(JC-ABA系列)

產品分類 : 共擠吹膜機

JC-ABA系列為3層共擠的吹袋設備, 主要是以較低的生產成本生產高質量膜的最終解決方案。 ABA 3層共擠生產線由兩台高性能擠出機和3層ABA共擠模頭組成, 外層主要使用原始材料,而核心層則使用大量的CaCo3或內部回收的顆粒材料。此外,ABA 3層膜結構還具有比常規單層膜更高的強度特性,總體上給競爭市場帶來了優勢。

CT-ML系列吹袋機

產品分類 : 共擠吹膜機

Equipped with 2 extruders, A/B or A/B/A type blown film machine is able to produce two-layer film. Co-extrusion able to choose from AB to ABA, ideally for 2 layer film with different colour or apply CaCO3 in middle layer for cost saving, etc. Perfectly suitable to agriculture film, shipping bags, shrink film, consumer packaging and many others.

HDPE 單層系列吹膜生產線

產品分類 : 吹膜押出機

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

LDPE單層超高速吹膜機

產品分類 : 吹膜押出機

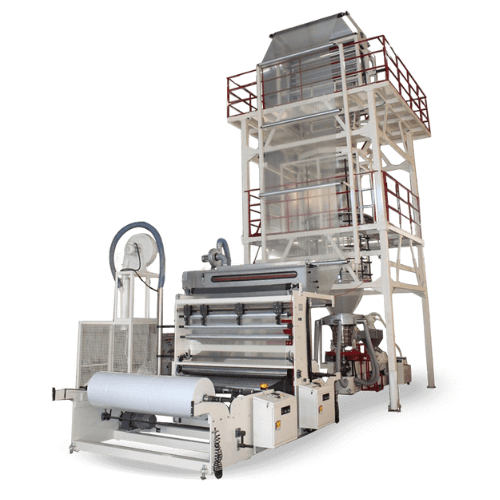

三層共擠FFS重包裝吹膜機

產品分類 : 吹膜押出機

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.

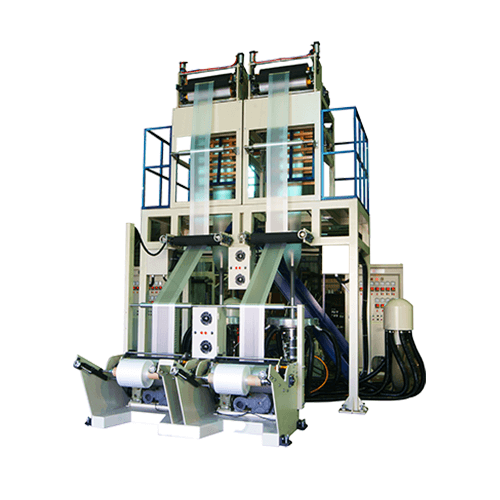

高速單層膜雙膜頭吹袋機

產品分類 : 吹膜押出機

This two-head blown film machine line can produce 2 film rolls of the same width at the same time, and the production capacity is thus comparatively higher than models with only one die head. Thanks to the twin-head design, it not only occupies less space but also consumes less energy, which offers an economical solution for producing plastic bags of smaller width.

HR系列吹袋機

產品分類 : 吹膜押出機

Film width available from 2000 ~ 4000mm, excellent for heavy-duty bags. Unique die head and air ring design to achieve stable bubble and better even thickness film and bag. Gear box uses high torque and enforced lubrication system. Automatic surface winder with uploading device. Oscillating haul-off. Blown film machine with oscillating haul-off system, built under the supervision of professional European engineers. AC inverter motor is designed for high production, quality and reliability to produce tubular film. High torque gear box with enforced lubrication system to minimize machine shutdown time. Good mixing performance of screw and barrel results in homogeneity and high output. Oscillating haul-off unit allows minimum web tension that eliminates wrinkle or bulge problem. High volume air ring is designed for ideal cooling efficiency.

HDPE High Speed Mono Layer Blown Film Machine

產品分類 : 吹膜押出機

Application: T-shirt bags, shopping bags, garbage bags, mattress cover, laundry bags etc. Suitable material: HDPE / MDPE / HDPE+LLDPE Film layer: 1 layer Screw L/D ratio: 30:1 Direct-connection design gearbox. PID+SCR temperature controller. ABB or HITACHI inverter. Gusset device.