尼龍 6 工程塑膠 - NA7200GK35

產品分類 : PA樹脂/尼龍

35%玻璃纖維增強 (黑色-高剛性、高耐衝擊) 應用說明:手工具、電動工具、園藝工具用,汽車、機車、腳踏車零組件用,運動器材零組件用,電子、電器外殼及零組件用,O.A.辦公室零組件用,水資材用,醫療復健器材。

尼龍 6 工程塑膠 - NAT7200

產品分類 : PA樹脂/尼龍

(黑色-低溫耐衝擊) 應用說明:手工具、電動工具、園藝工具用,汽車、機車、腳踏車零組件用,運動器材零組件用,電子、電器外殼及零組件用,O.A.辦公室零組件用,水資材用,醫療復健器材。

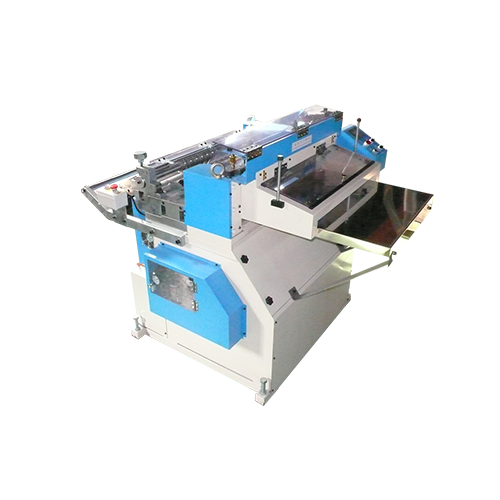

CONTRACT ASSEMBLY

Our Electronic Manufacturing Service (EMS) is used to Co- design, test, manufacture, distribute and provide repair services for electronic components and assemblies for Original Equipment Manufacturers. We have provided Co- design engineering and contract EMS for the consumer electronics, industrial, medical, military and telecommunications markets. We specialize in a variety of contract assembly levels from high volume, complex electro-mechanical assembly & testing to small volume, conceptual prototype runs. For small to medium device assembly, we utilize a cost savings system of mobile workstations and conveyors that can be quickly grouped into private and secure assembly cells. MANUFACTURING CAPABILITIES Electromechanical Assembly Subassembly and/or Final Product Assembly RoHS Compliant Assembly Lean Manufacturing PLM, MES, QMS, System Dedicated Program Management Functional and Post-Assembly Test Verification Material Procurement and Consigned Management FACILITIES 10,000 & 100,000 class clean rooms Flexible cell production system Mass management with Manufacturing Execution System (MES) 30,000 sq ft floor space with room for expansion Large, medium or small minimum order quantity (MOQ) HR expertise to maintain qualified production workers 24/7 operations SUPPLY CHAIN MANAGEMENT SERVICES YOMURA TECHNOLOGIES has many years of material & component sourcing experience and has direct relationships with factories around the world. Our office has been designed to coordinate quick quotes, provide constant updates and track all data needed to communicate with and expedite all client orders. This ensures a smooth transition from placement of orders to delivery. We understand our clients need to keep inventory levels low to control costs, yet still need to respond quickly for new orders to satisfy your customer demand. Clients can leverage our supply chain management expertise to receive volume quality products without high inventory risk. By customizing our stocking and logistics programs to meet your production needs we can reduce your material inventory during all stages of development from prototypes all the way through high volume production orders. TEST ENGINEERING Our Test Engineering department is staffed with experienced engineers and technicians who excel at working with customers to develop methodologies and design fixtures to reduce overall manufacturing costs, improve production yields, identify failures early, support root cause analysis, and assist design engineering with test analysis. Yomura has more than15 years waterproof IP68 test. REWORK SERVICES Sometimes rework of existing product assemblies is necessary to fix a design flaw, upgrade an assembly with a new components, or simply to find a cost down solution. Our rework specialists assure that resulting assemblies will meet the highest quality standards. CERTIFICATIONS QUALITY SYSTEM AS9100 / ISO 9001 / ISO 14001 / ISO 13485 / TS 16949 / UL Compliant / FDA / MFi

METAL INJECTION

產品分類 : 射出模具

Metal injection molding (MIM) is a metalworking process by which finely-powdered metal is mixed with a measured amount of binder material to comprise a ‘feedstock’ capable of being handled by plastic processing equipment. This is cost-effective for small, intricate, high-volume products which would otherwise be quite expensive to produce by alternate or classic methods. Mold Interconnect Device (MID) integrates a circuit into a plastic part reducing weight and dimensions. We use an innovative assembly process: from injected mold to laser etching then plating with copper or gold. APPLICATIONS Mobile phone’s aerial circuit Medical audiophones Automotive steering wheel Position sensor

尼龍 6 工程塑膠 - NA1100G45

產品分類 : PA樹脂/尼龍

Glass fiber 45% reinforced, high flow. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

MICRO MOLDING

產品分類 : 射出模具

Micro molding is a very specialized art form, which is a kind of tooling design , manufactures small and precision plastic components with polymer-based functional devices, by increasingly demanded in the fields of life science, electronics, medical, photonics, automotive, and aerospace. The tiny-scale molding form of injection molding that entails building a cavity to match the shape of the part you want to make, sort of like the plastic molding that makes Lego bricks. THERE ARE THREE DIFFERENT THINGS TO KEEP IN MIND WITH MICRO MOLDING : Micro means the size of the part. It is the most common definition when dealing with micro molding. Micro features relates to tiny parts on a larger part. As a whole, the part can be big, but its components can be smaller, or micro features. Micro tolerance is how the parts are measured and how close to the needed measurement the part has to be to be considered a good or usable part. When a part is molded, it has to measure within the needed measurement (the tolerance), which could be as small as a thousandth of an inch. Small parts that are simple to make have tolerances that are not as tight and would be considered regular molding. SOME ADVANTAGES OF DESIGN GUIDE IN YOMURA AS : Dimension Aspect ratios around 6:1 (material dependent) Wall thickness : 0.3 mm ( 0.012”) min. for plastic Hole dimension : 0.2mm ( 0.008”) – 0.5mm ( 0.02”) min. Pitch of hole : 0.3 mm ( 0.012”) – 0.50 mm ( 0.02”) min. Tolerance (min) : 0.01 mm ( 0.0004”) – 0.02 mm ( 0.0008”).