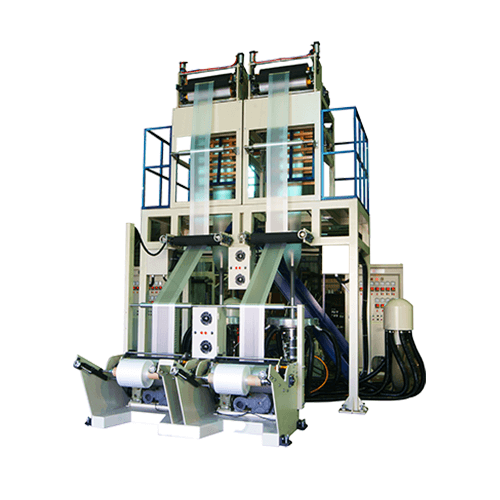

多層拉伸套膜吹膜機

產品分類 : 吹膜押出機

People replace stretch wrap film with stretch hood film. The stretch hood film has excellent holding force and extraordinary elasticity, so that it could cover the cargo tightly and prevent the stacked sacks from collapsing. It improves the security in logistic transportation greatly. Furthermore, it has high puncture resistance to protect the goods and provides good transparency that assist people to distinguish the content of cargo and to scan the labels. Specification Layers: 3 / 5 layer Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. Film width: 1500 ~ 1850 mm Output: 280 ~ 450 kg/hr

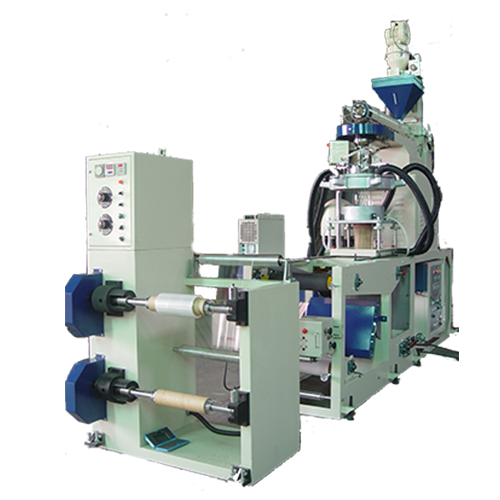

HDPE單層超高速吹膜機

產品分類 : 吹膜押出機

HDPE 單層系列吹膜生產線

產品分類 : 吹膜押出機

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

農業用膜及土工膜吹膜設備

產品分類 : 吹膜押出機

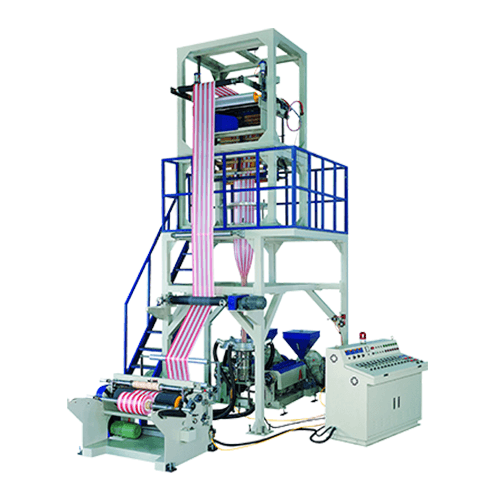

三層共擠FFS重包裝吹膜機

產品分類 : 吹膜押出機

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.