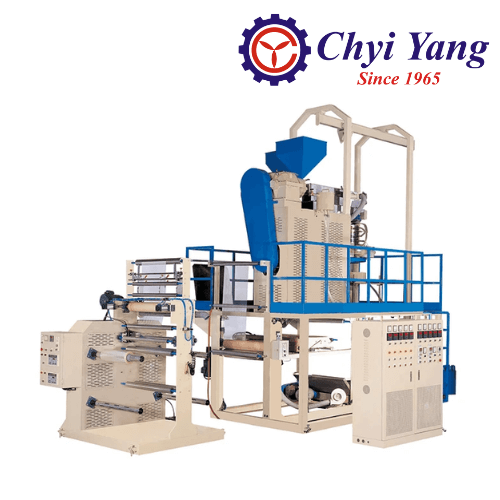

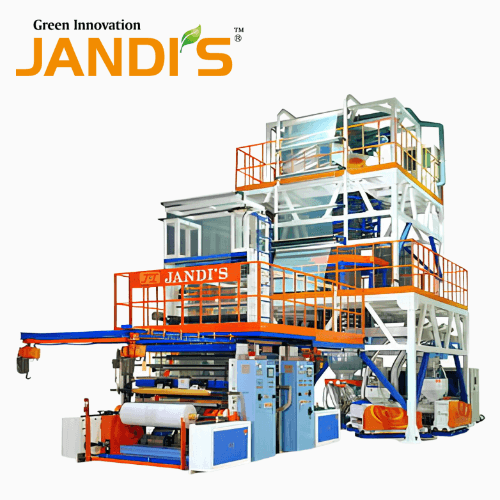

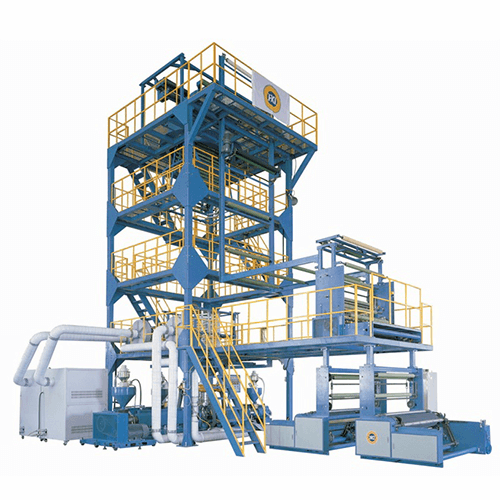

雙層共擠押高速吹膜機

產品分類 : 共擠吹膜機

搭配不同配備可生產農業用膜薄膜、溫室農膜、貼合用膜、雙層延伸膜、保潔膜、線性低密度薄膜、收縮膜、PE流延膜等 最大膜寬可到4.2米,剖單邊打開可到8.4米 使用原料: 高密度、低密度、線性低密度、EVA、中密度、PP等 配備兩台獨立式齒輪箱、兩組馬達、兩台主機及兩組獨立式的控制 以生產PE延伸膜及保潔膜而言,購買PIB黏劑注射系統可將黏劑直接注射入螺桿,可自行調整黏性並節省原料成本 PIB黏劑注射系統可生產外層無黏劑來防塵,內曾有黏劑用來包裝 選購耳料回收機可將分條下的廢料直接再入主機,以確保無廢料的產生 以下的規格並未展示所有型號,麻煩聯絡我們以詢問更大的吹膜機

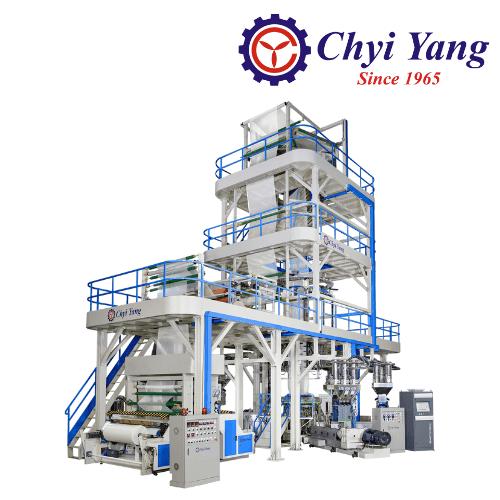

三層共擠押高速吹膜機

產品分類 : 共擠吹膜機

搭配不同的配備可生產農業用膜薄膜、溫室農膜、貼合用膜、建築用模、食品包裝薄膜、彩藝袋、重包裝袋、收縮膜、冷拉伸套膜等 最大膜寬可到4.2米,剖單邊打開可到8.4米 使用原料:高密度、低密度、線性低密度、EVA、中密度、PP等 配備三台獨立式齒輪箱、三組馬達、三台主機及三組獨立式的控制 可選配360度上旋轉可實現薄膜厚度均勻,用於淋膜及印刷,並避免旋轉器的缺點 可選購耳料回收機可將分條下的廢料直接再送入主機,以確保無廢料的產生並減少成本 我們未展示所有型號,若需更大的吹膜機,請隨時與我們聯繫

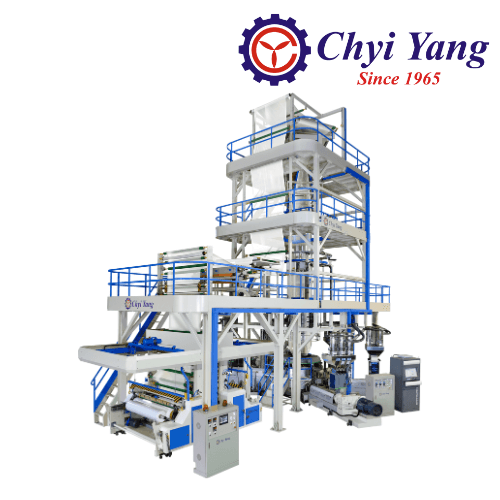

五層共擠押高速吹膜機

產品分類 : 共擠吹膜機

其陽工業製造五層共擠押高速吹膜機, 多層共擠押高速吹膜機,我們為食品和牛奶包裝..等等,生產均勻的薄膜。螺桿為雙金屬和精密模具,具有超過 50 年的生產多種吹膜機設備經驗

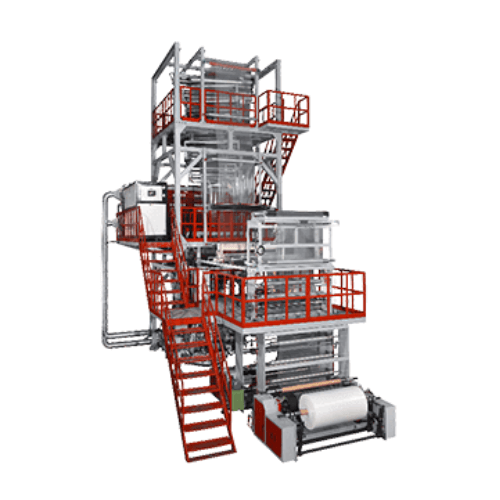

七層共擠押高速吹膜機

產品分類 : 共擠吹膜機

其陽工業製造七層共擠押高速吹膜機, 多層共擠押高速吹膜機,我們為食品和牛奶包裝..等等,生產均勻的薄膜。螺桿為雙金屬和精密模具,具有超過 50 年的生產多種吹膜機設備經驗

ABC三層共擠吹膜機

產品分類 : 共擠吹膜機

依托多年的擠出製造經驗,我們了解塑料吹膜擠出製程的各項原理,我們具有吹膜生產線的製造能力。此外,富隆的塑膠吹膜機,是依據原料特性及最終應用而量身訂做。在產品設計前,恆隆重視與客戶的溝通與討論,以建立與客戶的依賴。依據原料的用途,我們提供從 3 層到 5 層的共擠塑膠吹膜機。此外,最終產品在大幅降低成本的同時,也具備了所有所需的特性。

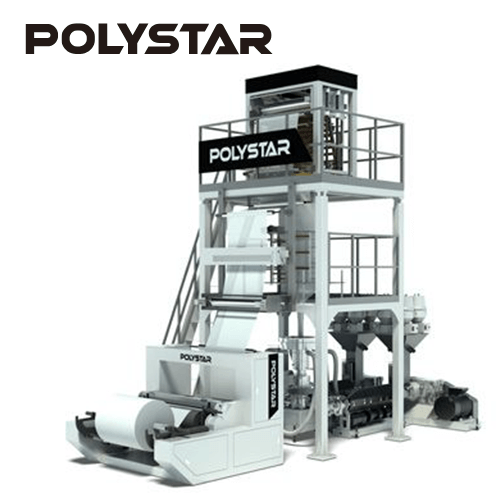

Blown Film Machine BFS-55-65-55-1400

產品分類 : 吹膜押出機

FKI提供最先進和適應性最強的吹塑薄膜生產線之一,如購物袋,背心袋,垃圾袋,農用薄膜,建築膜,包裝薄膜和復合薄膜等。可以使用的可用材料是如LDPE,LLDPE,MLLDPE和HDPE。薄膜生產範圍從200毫米到7米不等,生產產量從40公斤/小時到800公斤/小時。基於30年的經驗,FKI能夠提供具有可靠性和多功能性的吹膜生產線,以滿足單層,雙色,雙層,三層到四色設計的不同要求。

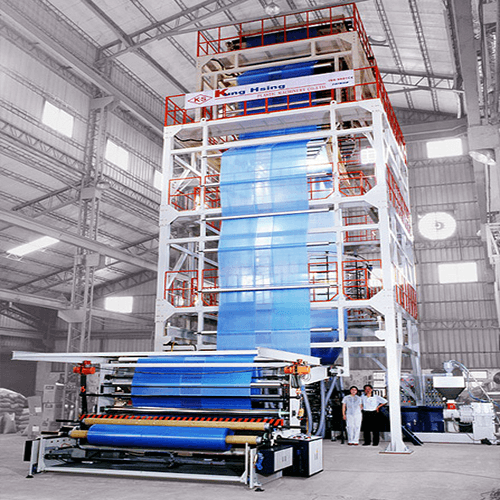

五層、七層複合吹袋機

產品分類 : 共擠吹膜機

光興已達到ISO 9002的要求, 機台符合CE的標準, 使光興成為一個世界級的公司, 不僅如此, 每台機台在運送至用戶端前都必須通過光興嚴格仔細的品管系統和測試。

A/B/A BFT Series Co-Extrusion Blown Film Line- Oscillating Tower Type

產品分類 : 共擠吹膜機

管狀平放寬度:40mm至7米。 -單層,兩層,三層和五層-單色,雙色,最多4色。

HDPE/LDPE/LLDPE三層共擠吹袋機

產品分類 : 共擠吹膜機

● ABA 3 Layer Co-extrusion ● Film Width from 500~1500mm ● Extruder Dia: 40mm,45mm, 55mm, 65mm ● Material: HDPE,LDPE, LLDPE,CaCO3, Additives ● Output: 45~150 kgs/hr

三層共擠吹膜機

產品分類 : 共擠吹膜機

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

ABA三層共擠吹膜機

產品分類 : 共擠吹膜機

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

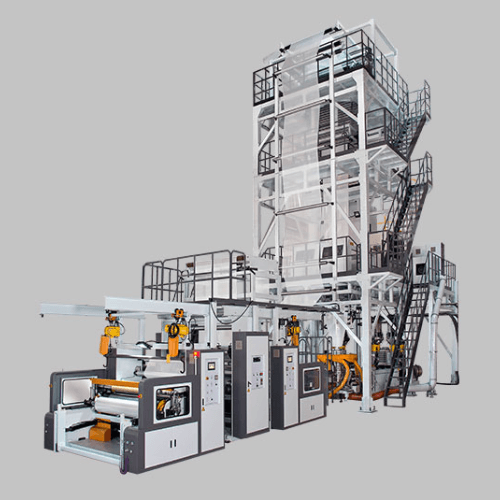

旋轉塔ABC三層膜吹袋機

產品分類 : 吹膜押出機

The ABC three-layer co-extrusion machine is your ideal choice for producing high-end plastic products, such as shrink films, agricultural mulches, electrical insulation films, packaging films, medical packaging films, stretch hood films. The raw material formula for each layer can be customized respectively according to your requirements. The oscillating haul-off unit provides excellent film gauge randomization, ensuring the production of high-quality and wrinkle-free films. The oscillating haul-off unit is also rather durable, and its equipment lifespan is much longer than the rotary die. Suitable for producing three-layer films for specific functions Recycled materials or CaCO3 is applicable to the middle layer in order to save material costs Die and air-ring specially designed for producing high-quality three-layer films 360° Oscillating Haul-off unit improves film thickness uniformity EPC (Edge Position Controller) Full customization according to your specific requirements

五層共擠吹膜機

產品分類 : 共擠吹膜機

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

CT-DC系列雙色吹袋機

產品分類 : 共擠吹膜機

Equipped with 2 extruders, A/B type blown film machine is able to produce two layer/two colours film. This machine can produce two-color-striped films. Final products have obvious streak of two separate colors. Upgrade die and air ring to produce HDPE and LDPE 2 layer film.

CT-ML系列吹袋機

產品分類 : 共擠吹膜機

Equipped with 2 extruders, A/B or A/B/A type blown film machine is able to produce two-layer film. Co-extrusion able to choose from AB to ABA, ideally for 2 layer film with different colour or apply CaCO3 in middle layer for cost saving, etc. Perfectly suitable to agriculture film, shipping bags, shrink film, consumer packaging and many others.