PLASCO Demonstrates its Innovative Strength and Unveils its Latest Monofilament Extrusion Technology at K2022 Düsseldorf Germany

PLASCO is an industrial leader in design, manufactures, and distributes extrusion machinery worldwide for the production of Monofilament, Strapping Tape, Fibrillated tape, Blown Film and Melt Blown extrusion lines. At K2022, PLASCO will unveils progressive extrusion technology to international specialists under the motto “Engineered for Perfection”, demonstrate its technological innovation the field of monofilament extrusion. Visit us at K2022 in Hall 15 Stand C61...

Your Innovative Extrusioneers from PLASCO

PLASCO is an Industry leader in design, manufacture, and supply of innovative plastic extrusion line to the market worldwide. Our performance spectrum range from individual extruder machine, to the engineering, planning, and delivery of complete turn-key factories. We offer our customer our speciality knowhow in the field of plastic extrusion, our innovations and engineering background is our core competence to provide customized solution and has driven us success for more than 30 years. Our advantages • With 2 manufacturing factories in Taiwan including test center. • More than 3600 PLASCO extrusion lines all over the world • Installed the extrusion lines in more than 80 countries worldwide • Focus on innovation and quality: independent R&D dep. and electrical engineer • Customized and top quality to satisfy customers • Convenient to find spare parts all over the world: we use the well-known global components for machines Work with PLASCO • Customized design & auxiliary equipment provided • Efficiency & exact lead-time • Service & support: installation, operation training, and technical knowledge support • CE certificate of compliance With its high level of reliability, efficiency, energy saving concept, and top quality finish product, PLASCO plastic extrusion line ensures the modest investment compared with its high productivities to facilitate the ever-demand requirement of all market sectors.

GMA at K 2022 Showcasing and Remaking the Concept of Extrusion Molds and Dies

K Fair is coming back and the leading players in the plastics and rubber industry are going to be present. Representing Taiwan as one of the most successful and recognized companies in the Extrusion molds and Dies industry, GMA is going to have different Molds and Dies a such as their special Hastelloy C276 steel Mold, which is highly resistant to corrosion, which is worth it to mention that is very suitable for the fluorine-containing plastic application, without electroplating.

HAN KING: Blown Film Machines for FFS Heavy-duty Sack and Stretch Hood Film Play a Significant Role in the Petrochemical Industry

Han King is a professional blown film machine manufacturer in Taiwan. It has full design and manufacturing capability from custom design to final machine built. In-house R&D team focus on automation, development, manufacturing, assembly and communication to customize each customer's unique requirement...

CHEN WAY: 4 Must-Know Tips to Cost Saving and Eco-Friendly of Blow Molding Machine

In the case of extrusion blow molding, companies around the world look for ways to start eco-friendly and cost-saving production. This article will therefore let you know some must-know tips to achieve this. Why should a blow molder care for sustainability?

TUNG YU Hydraulics will Meet You at TaipeiPLAS2022

In the post-epidemic era, companies are highly anticipating the recovery of international business, after four years of absence, TUNG YU will meet you again at the TaipeiPLAS2022 from September 27 to October 1 this year at the TaiNEX 1 Hall1. In response to the current energy transformation, carbon reduction, and zero issues, combined with green energy and industry 4.0, TUNG YU will exhibit the latest development of a full range of solutions.

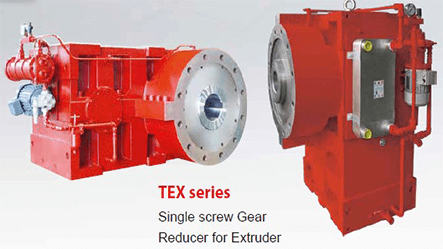

TIEN YI GEAR: The Pioneer Of Gear Elements

We are specialized in all different kinds of Transmission Issue. CUSTOM-MADE in tailored customers demand. Our strong R&D team has capability to solve different kind of transmission issues in order to upgrade equipment's efficacy & proper rate. OEM & ODM as per your demand.

LIN CHENG: The Automation Trend of Rubber and Silicone Injection Molding Machines

For more than four decades Lin Cheng Technologies has shown its great expertise around the world on creating exclusive services for customers. We stand out in the field for manufacturing rubber injection molding machines, silicon rubber injection molding, vacuum compression molding, thermoforming, thermosetting, carbon fiber molding, powder forming and other types of compression molding machines.

Xiang In: How Is Having A Quality Labeling Design Increases Your Final Product’s Value

Nowadays, most of the products that we consume on a daily basis contain different kinds of labels promoting a brand or a message to its consumers. Xiang In Enterprise is one of the biggest manufacturers, with two decades of expertise in the industry, specialized and dedicated to the manufacture of heat transfer machines and films and in-mold labels (IML).

GMA: What has been the Situation for the Extrusion Molds and Dies Market During 2022?

Since the beginning of the pandemic, it is well known that most of the industries didn't have stable performance when it comes to product demands, this is due to the situation creating new needs, especially in the medical and packaging industry, where the demand increased exponentially. GMA was not the exception, as we mentioned in E-NEWS year 2020, there was a huge demand for Meltblown Dies because of the high need for face masks worldwide.

TungYu: Servo Press- Bringing the Power of Change to Create a Greener Future

In today's manufacturing industry, traditional hydraulic presses no longer meet the needs of production efficiency and the environment. With the spirit of continuous innovation and prioritizing customer needs, TUNG YU has developed a new servo press. Energy-saving and precise force application, using clean energy to increase production capacity, is an optimized high-quality solution.

Your Innovative Extrusioneers from PLASCO

PLASCO is an Industry leader in design, manufacture, and supply of innovative plastic extrusion line to the market worldwide. Our performance spectrum range from individual extruder machine, to the engineering, planning, and delivery of complete turn-key factories. We offer our customer our speciality knowhow in the field of plastic extrusion, our innovations and engineering background is our core competence to provide customized solution and has driven us success for more than 30 years. Our advantages • With 2 manufacturing factories in Taiwan including test center. • More than 3600 PLASCO extrusion lines all over the world • Installed the extrusion lines in more than 80 countries worldwide • Focus on innovation and quality: independent R&D dep. and electrical engineer • Customized and top quality to satisfy customers • Convenient to find spare parts all over the world: we use the well-known global components for machines Work with PLASCO • Customized design & auxiliary equipment provided • Efficiency & exact lead-time • Service & support: installation, operation training, and technical knowledge support • CE certificate of compliance With its high level of reliability, efficiency, energy saving concept, and top quality finish product, PLASCO plastic extrusion line ensures the modest investment compared with its high productivities to facilitate the ever-demand requirement of all market sectors.