Essential Tips for Choosing the Best PVC Pipe Extrusion Line

Selecting the right PVC Pipe Extrusion Line for producing high-quality pipes is a critical decision for any manufacturing operation. It affects production efficiency, product quality, and long-term profitability. Before getting overwhelmed by the numerous options available, it’s important to focus on evaluating key factors. This comprehensive guide will highlight essential considerations to help you make an informed choice.

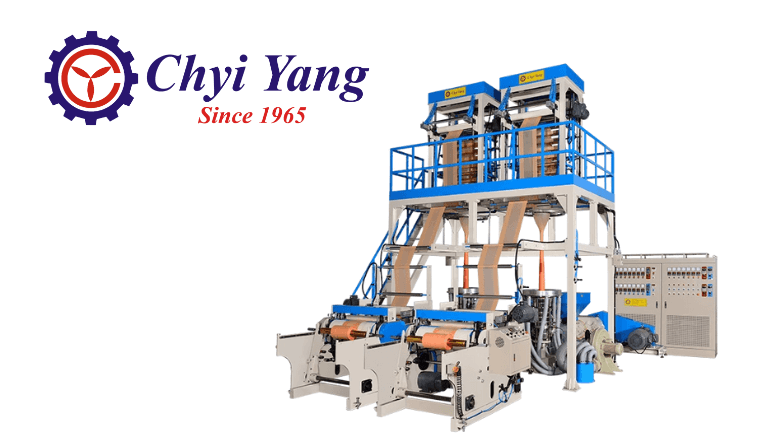

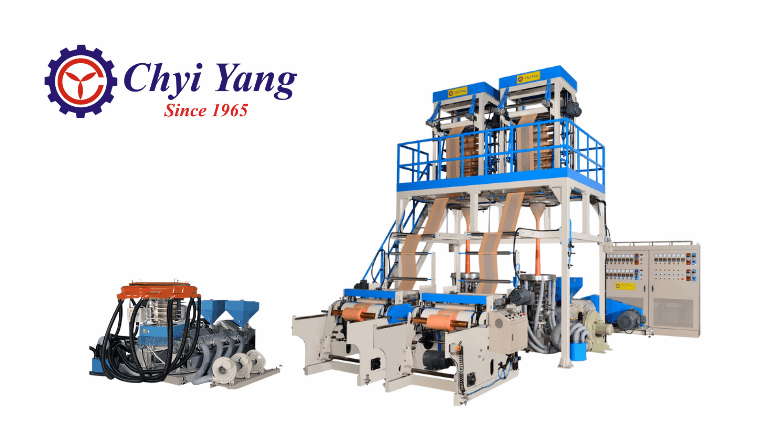

Advantages of ABA Co-extrusion Blown Film Machine

A co-extrusion process uses more than one polymer to form the plastic bubble and therefore more layers to the film. The most prevalent blown film process today is the ABA co-extrusion process. One of CHYI YANG's most popular machines is also the ABA co-extrusion blown film machine. The term ABA indicates the three-layer structure of the film, two outer layers, and one inner layer, hence ABA. The materials of the A layer and B layer are different. The outer layer typically uses new materials, whereas the inner layer uses recycled materials. Using more than one material leads to several advantages and installation adjustments on the ABA blown film machine. As a leading plastic film machinery manufacturer in Taiwan, today CHYI YANG will talk about the advantages of this kind of blown film machine and how it can help your business.

Taiwan Kinki: Leading the Charge in Golf Ball Machinery Manufacturing

As golf continues to surge in popularity worldwide, Taiwan has firmly established itself as a pivotal hub in the global golf ball industry. According to the Ministry of Finance's 2023 statistics, Taiwan’s golf ball exports have captured over 30% of the global market share, with export revenues soaring to $710 million. Amidst this thriving landscape stands Taiwan Kinki (台灣今機), a trailblazer in high-precision golf ball machinery, poised to become the preferred partner for international buyers seeking top-tier production equipment.

Revolutionizing the Market: CHYI YANG's Smart 5/7-layer Blown Film Machines Lead the ESG Sustainability Trend

Chyi Yang's Smart 5/7-layer Blown Film Machines revolutionize plastic film production, reducing costs and material waste while complying with regulations. Their Auto-recycling blown film machines use precision formula calculations and advanced recycling mechanisms to improve production yield and achieve "ZERO WASTE" while reducing energy consumption to improve competitiveness.

From Waste to Worth: Genius Machinery’s Green Engineering

GENIUS Machinery is renowned globally in the plastic recycling machinery market for its advanced technology and customized solutions. Ever since it started, GENIUS has not only focused on environmental protection and the circular economy but has also been dedicated to comprehensive factory planning for plastic recycling systems. With over 40 years of experience in the design and manufacturing of recycling machinery, the company offers a complete range of solutions, including plastic washing lines, recycling machines, pelletizers, squeeze dryers, crushers, and shredders. Worldwide Market Deployment: Strengthening Global Presence

PE Cling Film Market Trend: Sustainability and Clean Production

The use of cling film has substantially expanded in recent years in response to the increased demand from global pharmaceutical and F&B industries. This is especially true considering that manufacturers have developed many special-purpose films to boost market appeal. North America currently dominates the cling film market; however, the market for cling film has become a hot spot for rapid growth due to the urbanization of developing regions in the Asia Pacific, including China, India and Southeast Asia.

Mastering PVC Twin Screw Extruders: Your 3-Minute Essential Guide

PVC Twin Screw Extruders are a type of plastic processing machine that melts, blends, and incorporates PVC resin into a homogeneous melt. The melt is then extruded through a die to form the desired shape of the final product, such as pipes, profiles, films, sheets, or foams. This guide provides a comprehensive overview of PVC Twin Screw Extruders, covering their process, key components, applications, and how to choose the right one for your needs.

How to Choose the Right POLYSTAR Recycling Machine Based on Your Plastic Waste?

Follow the guidelines to choose the right POLYSTAR plastic recycling machine that processes your plastic waste efficiently and with a high yield.

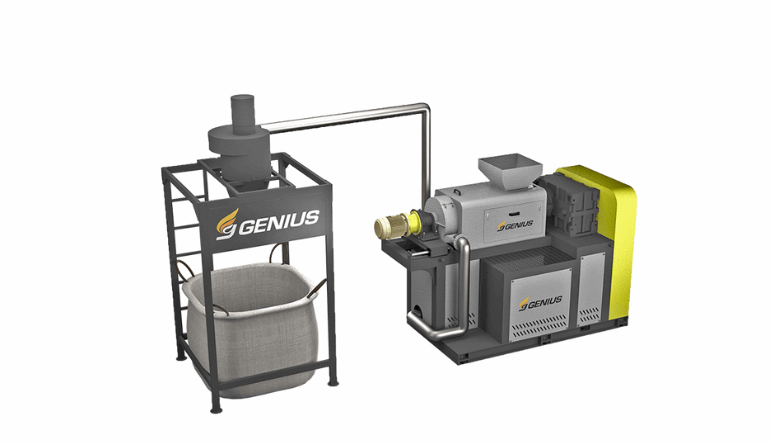

How Screw Press Dewatering Machines Are Transforming Plastic Film Recycling

Plastic waste has become a major environmental challenge, particularly with the growing use of plastic films in agriculture, packaging, and various industries. Recycling plastic films such as agricultural film and stretch film requires efficient dewatering to improve material quality and reduce waste. Among the most effective solutions is the screw press dewatering machine, designed to extract moisture from plastic films during the recycling process. In this blog, we’ll explore how screw press dewatering machines are transforming plastic film recycling, boosting efficiency, and contributing to a more sustainable future.

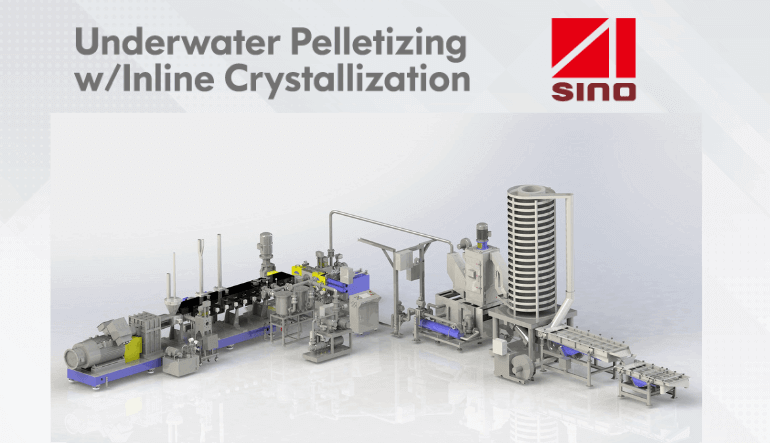

Sharing Success Stories: How Choosing Sino-Alloy, the Compounding Expert, Can Bring You Production Advantages

Sino-Alloy Machinery Inc. is a leading company specializing in the manufacturing of co-rotating twin-screw extruders, widely applied in various fields such as engineering plastics, adhesives, and plastic wood compound. Committed to continuously improving efficiency, quality, and reliability, Sino has attracted numerous domestic and international buyers. Sino's technology not only helps customers enhance production efficiency but also demonstrates significant achievements in environmental protection and energy conservation, further consolidating its leadership position in the market.

The Smart Choice: CHYI YANG Yang's ABA 3-Layer Co-Extrusion Reach the Perfect Combination of High Performance and Precise Cost Control

With consistently increasing sales and highly positive feedback from customers, Chyi Yang’s newly launched ABA 3-Layer Co-Extrusion has quickly gained traction in the market. Its strong competitive edge in reducing production costs, improving efficiency, and maintaining superior product quality has made it a standout performer. The machine’s impressive sales and exceptional customer satisfaction have solidified its position as a rising star in the industry.

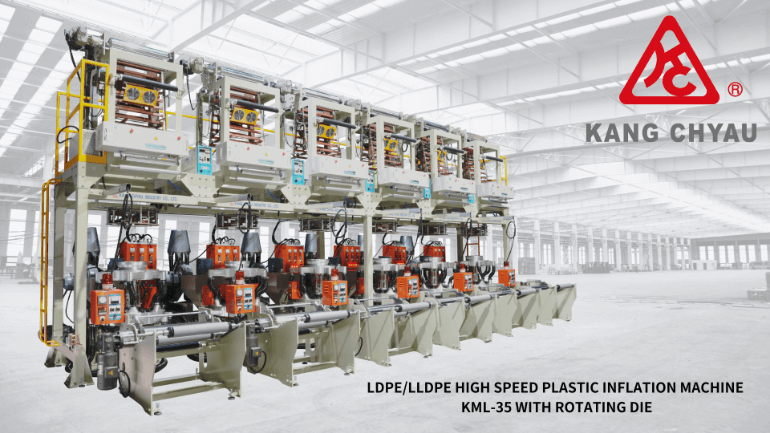

從通用到客製化吹膜機械:康喬工業從滿足多元客戶需求蛻變成為吹膜專業顧問

來自台灣的康喬工業,專注於塑膠吹膜機的研發與製造,由康忠義先生創立於1988年,憑藉其專業知識和技術,買家遍及全球,也展示出在滿足多樣化客戶需求方面的靈活性和彈性。創業初期,康喬創新地使用3.5噸貨車運送全新的吹袋機,進行全台巡迴展示,這種「現場試機,直接銷售」的模式,除了讓國內買家能看到實機,還能快速瞭解機台的運作流程及優勢,使康喬迅速贏得了國內市場的認可。當國內市場穩定後,康喬便積極參加國際展覽,此舉也大大提升國際能見度,獲得國際市場認可,讓更多國際買家認識康喬,康喬也從此打開通往國際市場的大門。