近期更新 立即訂閱

Exploring the Cutting Edge of Plastic Film Technology — Don't Miss Chyi Yang's ABA 3-Layer Co-Extrusion

As a leader in plastic film machinery, Chyi Yang has maintained a solid market position and demonstrated excellence for 60 years. At this year’s TaipeiPLAS, Chyi Yang will showcase its latest ABA 3-Layer Co-Extrusion, renowned for its outstanding cost control capabilities and production efficiency. This machine has become a highlight that industry professionals cannot afford to overlook. This article will delve into the machine's features and invites you to visit Chyi Yang's booth: M0416 to explore the forefront of industry technology.

CHINAPLAS 2025: Shaping the future of film extrusion with high-efficiency co-extrusion system

At CHINAPLAS 2025, Chyi Yang Industrial Co., Ltd. exhibits its innovative multi-layer co-extruded blown film systems. An interview with Sales Director, Antonio Jo.

How to Choose the Right Blown Film Machine: Why CHYI YANG Is Your Best Bet for Consistency and Profitability

Selecting the ideal blown film machine is crucial to your production success. This practical guide highlights key pain points—like uneven film thickness and waste management—and explains why Chyi Yang’s advanced machinery ensures consistent film quality, increased yield, and long-term profitability. Make your blown film production smarter and greener.

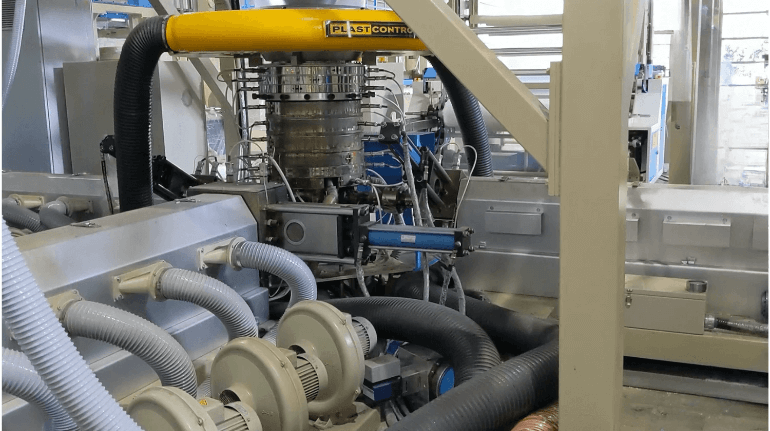

OEM with Italy Manufacturer for Better 3-layer Co-Extrusion Film Quality

Chyi Yang showed one set 3-Layer Co-Extrusion Blown Film Machine in 2014 Taipeiplas exhibition. We cooperated with Italy SYCRO to produce main parts including IBC, 3-layer co-extrusion die, air ring, automatic width & thickness controller. The internal bubble control (IBC) is available for film cooling & increasing output. Film width is set up by touch screen instead of manual operation. According to the oil price increases & not stable, Chyi Yang uses Automatic Thickness & Width Control to control the difference range between ±5% to save resin cost. The air ring is up-and-down moveable in order to improve the cooling when you run high speed. There are 48 points in air ring to adjust the thickness automatically. The extruders are 65mm & 90mm & 65mm, equipped with motor 75HP & 100HP & 75HP. The max. film width is 1500mm & the capacity is max. 8.4tons per day.

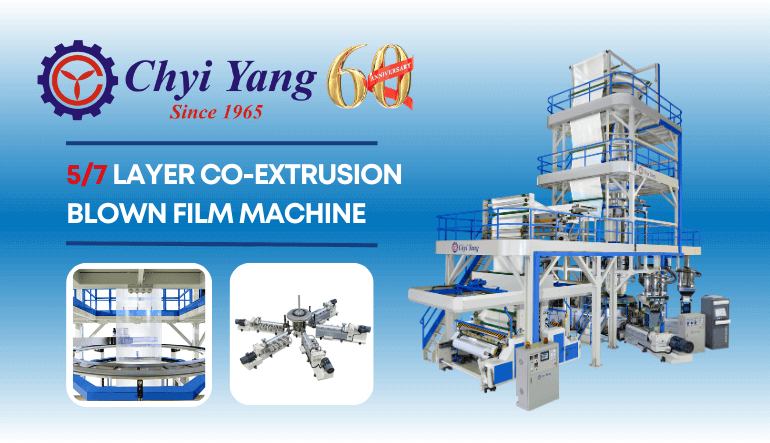

Leading the Future of Green Manufacturing: CHYI YANG's Innovative 7-Layer Blown Film Solutions

With the rise of ESG sustainability goals and increasing global environmental awareness, the plastic film manufacturing industry faces a significant shift towards technological upgrades. Chyi Yang plastic machinery is at the forefront of innovation, launching its advanced 7-Layer Co-Extrusion High-Speed Blown Film Machine, which not only enhances production efficiency but also aligns with market demand for eco-friendly manufacturing.