近期更新 立即訂閱

From Mold to Marvel: How Jia Thai Delivers Beauty and Precision, One Injection at a Time

When it comes to injection mold manufacturing, there are plenty of options. But few combine technical precision, aesthetic finesse, and decades of experience quite like Jia Thai Industrial Co., Ltd. Founded in 1990 in Taiwan, Jia Thai has quietly built a reputation over the past 30+ years as a reliable partner for high-end mold solutions—especially in the cosmetic and automotive sectors.

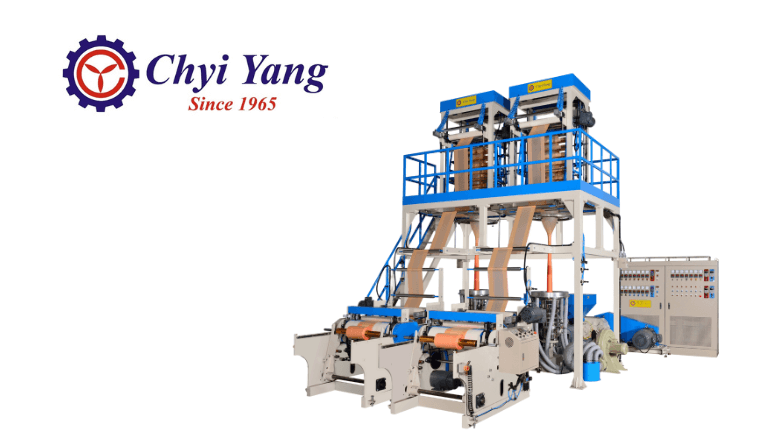

Exploring the Cutting Edge of Plastic Film Technology — Don't Miss Chyi Yang's ABA 3-Layer Co-Extrusion

As a leader in plastic film machinery, Chyi Yang has maintained a solid market position and demonstrated excellence for 60 years. At this year’s TaipeiPLAS, Chyi Yang will showcase its latest ABA 3-Layer Co-Extrusion, renowned for its outstanding cost control capabilities and production efficiency. This machine has become a highlight that industry professionals cannot afford to overlook. This article will delve into the machine's features and invites you to visit Chyi Yang's booth: M0416 to explore the forefront of industry technology.

CHINAPLAS 2025: Shaping the future of film extrusion with high-efficiency co-extrusion system

At CHINAPLAS 2025, Chyi Yang Industrial Co., Ltd. exhibits its innovative multi-layer co-extruded blown film systems. An interview with Sales Director, Antonio Jo.

Tips for Selecting the Right Hydro Dipping Film: Factors to Consider for Your Project

One of the key elements in achieving a successful hydro dipping project is selecting the right water transfer printing film. With numerous options available in the market, it's important to consider several factors to ensure the perfect match between your project requirements and the hydro dipping film. In this blog, we will provide you with essential tips for selecting the right film, taking into account factors such as the material and the desired design.

How to Choose the Right Blown Film Machine: Why CHYI YANG Is Your Best Bet for Consistency and Profitability

Selecting the ideal blown film machine is crucial to your production success. This practical guide highlights key pain points—like uneven film thickness and waste management—and explains why Chyi Yang’s advanced machinery ensures consistent film quality, increased yield, and long-term profitability. Make your blown film production smarter and greener.

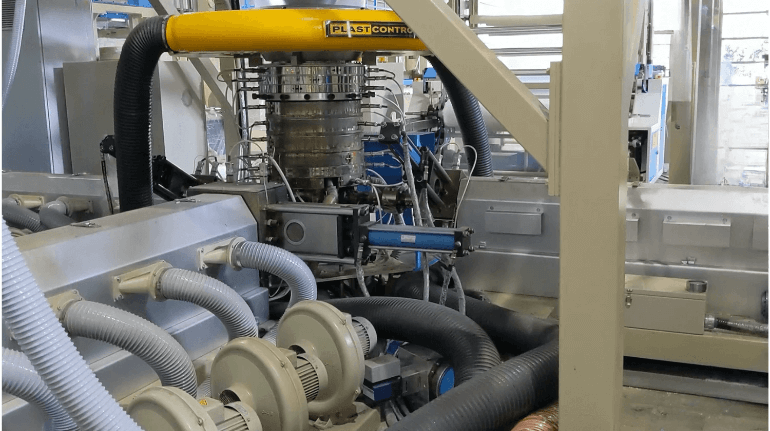

BoReTech: Comprehensive Solutions for Plastic Recycling

BoReTech is at the forefront of global plastic recycling, providing cutting-edge technology and comprehensive engineering solutions to enhance sustainability in the industry. With expertise spanning PET, PP, HDPE, and mixed plastic recycling, we offer a complete suite of innovative solutions designed to meet the evolving needs of recyclers worldwide.

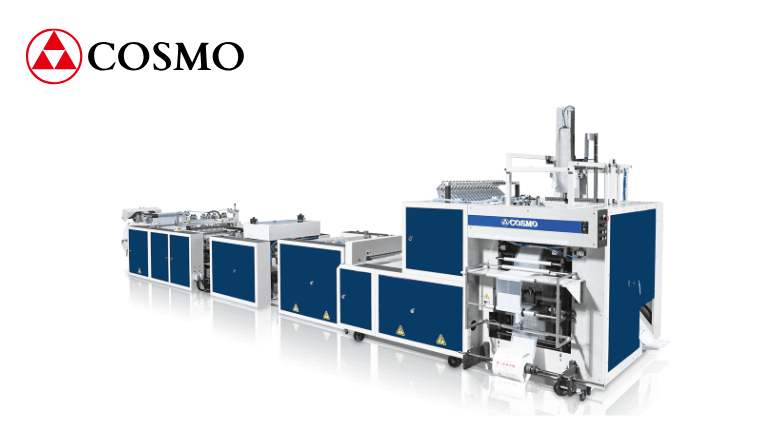

How to Choose the Right Garbage Bag Manufacturing Machine to Boost Efficiency and Profitability?

If you're considering purchasing a garbage bag manufacturing machine, you're likely seeking equipment that enhances production efficiency, improves product quality, and ultimately boosts your profitability. In this article, we will discuss various types of garbage bag machines available on the market, highlight their key features, and outline the practical business advantages they offer.

Sustainable and Cost-Effective Film Production with ABA Blown Film Machines

ABA Blown Film Machines offer substantial advantages in plastic film production by effectively combining cost efficiency with enhanced durability and strength. Leveraging advanced extrusion technology, these machines improve film quality while significantly lowering material costs. Manufacturers benefit from flexible formulation options, such as incorporating recycled plastics, lower-cost raw materials, or CaCO₃ fillers.

Jumbo Steel: Leading Biodegradable Straw Technology in Line with K Show 2025’s Key Themes

Jumbo Steel Machinery Co. Ltd., a leading manufacturer specializing in biodegradable and PP straw-making machines, aligns with these industry trends by developing eco-friendly solutions that support the circular economy. With customers in over 120 countries, Jumbo Steel is at the forefront of automated straw manufacturing, offering sustainable alternatives to traditional plastic products.

Top-Roller: Where High Precision Meets High Customization

In precision rotary machinery manufacturing, only a handful of companies worldwide can achieve both high customization and exceptional quality. Top-Roller Co., Ltd., based in Taiwan, stands out as a leader in this industry. With over 30 years of manufacturing experience, Top-Roller is dedicated to providing high-efficiency, durable, and fully customized aluminum idler rollers for the global rubber, plastics, and packaging industries.

Creative Ideas for Using Hydro Dipping Film : Elevate Your Decor Game!

Hydro dipping film, also known as water transfer printing film, is a versatile and innovative solution for adding vibrant and eye-catching designs to various objects. From automotive parts to firearms, sporting goods, and household items, hydro dipping film can transform ordinary objects into extraordinary works of art. In this blog, we'll explore some exciting and creative ideas for utilizing hydro dipping film to elevate your decor game and make a lasting impression.

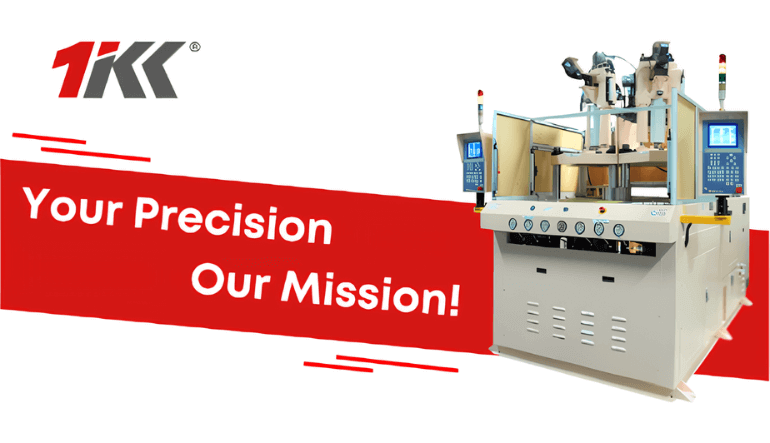

Flexible and Precise: Taiwan Kinki’s Vertical Injection Molding Machine Powers Cosmetic Manufacturing

Taiwan Kinki Machinery Co., Ltd.'s professional vertical injection molding machine is expertly designed to address the sophisticated needs of the cosmetics industry. Specifically engineered for precision applications, this advanced machine produces core components like lipstick bullets, which require impeccable dimensional accuracy and a flawless surface finish.