近期更新 立即訂閱

Visit NAN YUN at PLASTIMAGEN 2025: Shaping the Future of Screws and Barrels Technology

Established in 1993, NAN YUN Industrial Co., Ltd. is a leading supplier of essential components for injection molding machines, extruders, and related machinery in the plastic and rubber industry. Our dedicated engineering design team combines exceptional theoretical knowledge with practical expertise, specializing in the meticulous design and production of a wide range of screws and barrels.

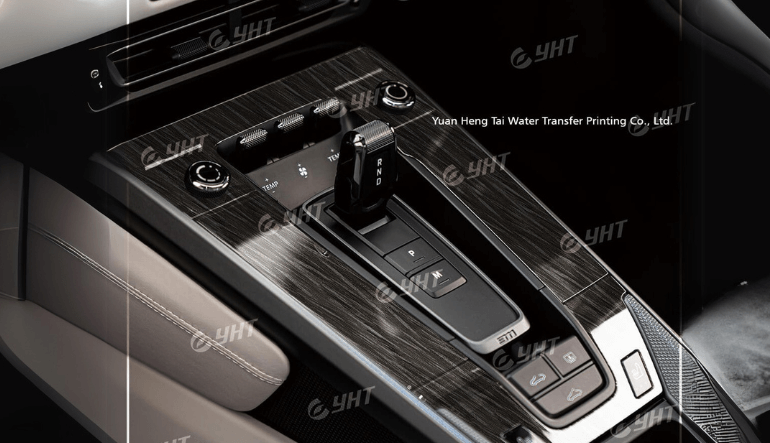

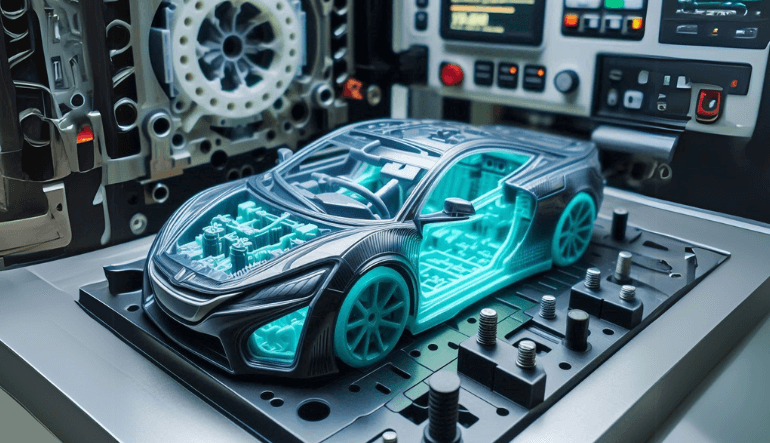

6 Main Reasons to Choose Water Transfer Printing as Surface Decoration Technique for Automotive Interiors

The automotive industry has been growing in recent years at a blistering speed. Every car manufacturer is keeping their eyes for the latest and affordable technologies that will bring their products to the top of the list in modern and futuristic cars. As an OEM manufacturer you should always be looking for the best surface decoration options available in the market for your customers. However there are too many surface decoration techniques for you to choose from and it might be hard to know which one is more suitable. Come explore with us your options.

Custom Fit, Maximum Impact: Chi Chang’s Approach to Extrusion Excellence

When it comes to bubble wrap making machines, Chi Chang’s 3-Layer Air Bubble Film Extrusion Line stands out as a revolutionary solution. Designed to meet diverse industry needs, this machine combines state-of-the-art technology with tailored solutions to ensure maximum efficiency and unparalleled performance.

YICHEEN: How Precision Cutting Machine Technology Leads the High-End Footwear Market

The 2025 K Show in Germany once again emerges as the global focal point for innovations in the plastics and rubber industry. This year’s event centers on three major themes: Circular Economy, Digitalization, and Caring about People. Under these trends, manufacturers must not only emphasize machine performance and durability but also prioritize operational safety and human-centric design.

From Bland to Bold : 6 Unique Automotive Interior Hydro Dip Patterns to Try Out

Looking to spruce up your car's interior? Look no further than hydro dip patterns for automotive interiors. Hydrographic films offer a versatile option for adding unique designs to your car's interior, with the ability to apply them to everything from the dashboard to the trim. However, it's not just about aesthetics - hydro dipping also provides benefits such as durability, scratch resistance, and heat resistance. In this blog, we will explore 6 unique hydro dip patterns for automotive interiors, as well as the advantages of working with a professional film manufacturer. So buckle up and get ready to take your car from bland to bold!

KaoLu 榮獲 2025年 German Design Award

KaoLu 在 2025 年榮獲 German Design Award,這項國際殊榮肯定了我們在壓力控制與流量控制比例閥領域的創新與卓越設計。 作為專業的比例閥製造商,KaoLu 始終致力於技術突破與精密工程,為全球客戶提供高性能、高可靠性的流體控制解決方案。

高鹿 - 流體壓力比例閥、音圈馬達壓力比例閥專利技術

高鹿於2023年獲得流體壓力比例閥、音圈馬達壓力比例閥專利技術, 通過結合跨學科的專業知識,為流程和工業自動化領域提供高速、高分辨率和革命性的數字化解決方案,相對提升帶動核心技術價值。

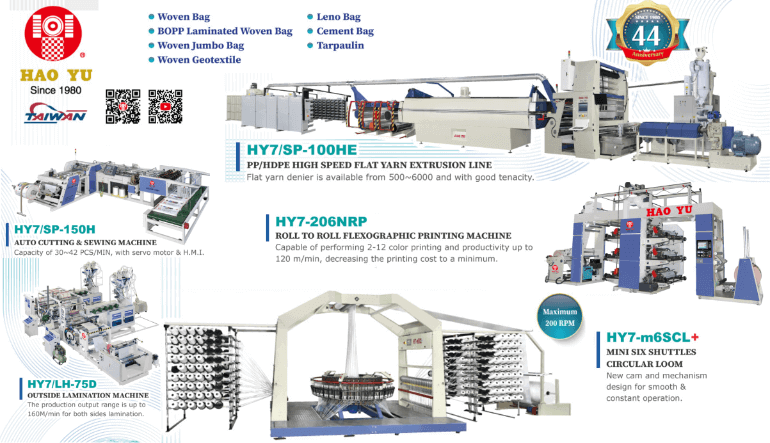

HAO YU: A Professional & Reliable Leading Supplier in Taiwan Provide 7 Turn Key Projects Solution For Plastic Woven Industries.

HAO YU Precision Machinery Industry Co., Ltd. is a one of the most skillful & experienced manufacturers of PP and HDPE and PET woven bag machinery and whole-plant equipment in Taiwan since 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence. Our objective is to enhance our present machinery and develop new models that improve the efficiency, product quality and profitability for our customers.

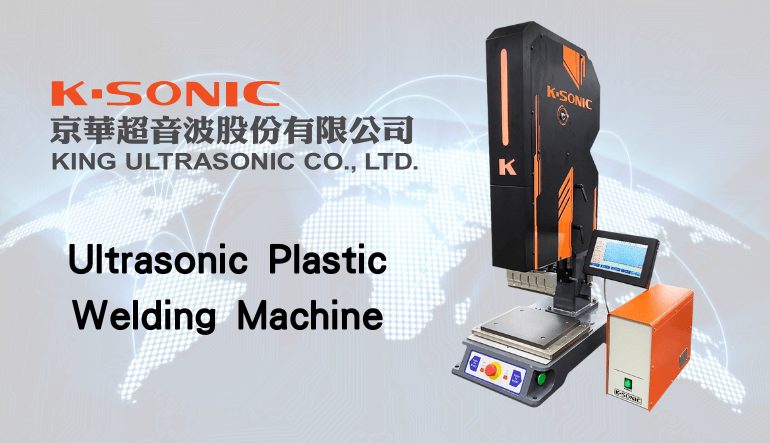

High Performance, Silent Operation, Precise Control — k-sonic Flagship High-Efficiency Clean Energy Welding Machine (30kHz 2000W / 20kHz 4000W) for Exceptional Quiet Environment and Welding Quality

The K-sonic Flagship High-Efficiency Clean Energy Welding Machine integrates cutting-edge technology with superior performance, providing a green solution to enhance equipment energy efficiency and reduce environmental noise pollution. Its precise positioning detection, pressure sensing, and energy control ensure flawless welding every time.

Insert Molding vs. Overmolding: Key Differences & Applications

In the field of plastic product manufacturing, Insert Molding and Overmolding Molding are two widely used techniques, each serving different purposes. Understanding their differences is crucial for selecting the right manufacturing process, especially in OEM car parts, consumer electronics, and medical devices.

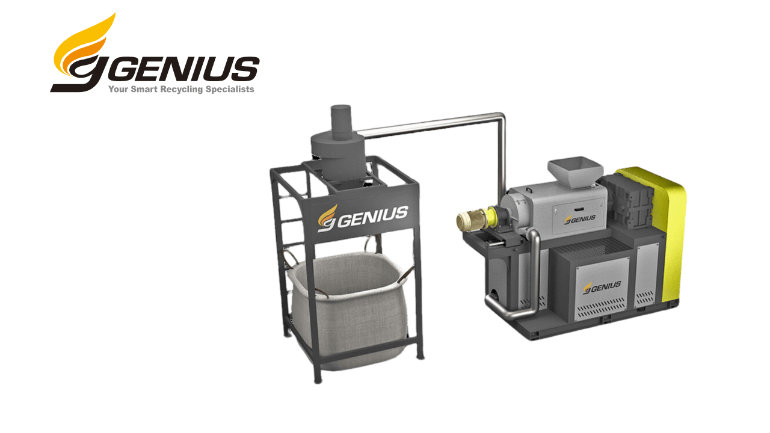

How Screw Press Dewatering Machines Revolutionize Plastic Film Recycling | GENIUS

Plastic waste has become a major environmental challenge, particularly with the growing use of plastic films in agriculture, packaging, and various industries. Recycling plastic films such as agricultural film and stretch film requires efficient dewatering to improve material quality and reduce waste.

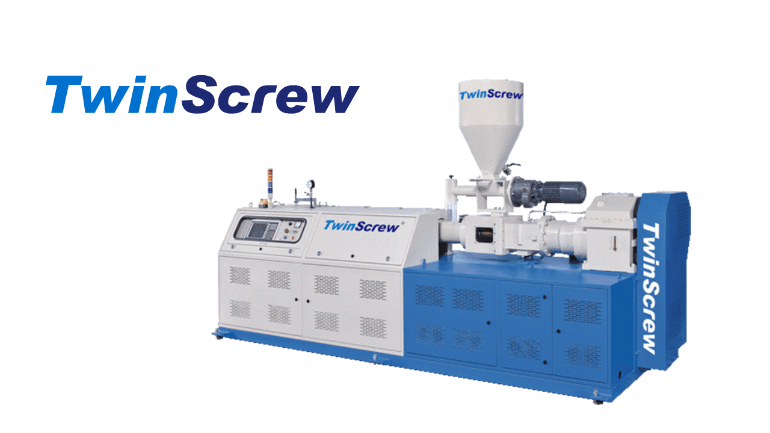

Medical Tube Extrusion Line : Key Insights and Case Studies | Twin Screw

In medical manufacturing, precision, efficiency, and reliability are critical to producing life-saving devices. PVC Medical Tube Extrusion Lines play a pivotal role in manufacturing essential products like IV lines, catheters, and respiratory tubes.