UNDERSTANDING WPC PROFILE MACHINES IN 5 MINUTES

WPC profiles have become increasingly popular due to their natural look and feel of wood combined with the durability and low-maintenance benefits of plastic. WPC profiles are widely used in the construction industry for outdoor decking, fencing, window, door frames and railing, as well as in automotive and furniture industries. WPC profile extrusion machines play a critical role in producing high-quality WPC profiles efficiently. In this article, we will explain the basics of WPC profile extrusion machines and how they work.

|

|

What is a WPC Profile Extrusion Machine?

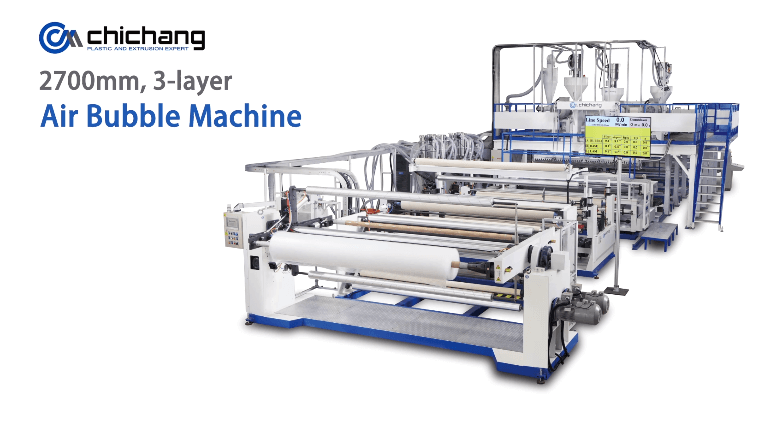

WPC Profile Extrusion Machines are designed with several components, including an extruder, a calibration table, a cutter, and a stacker. The extruder is the heart of the machine, responsible for melting the plastic and mixing it with the wood flour or fibers. It comprises a hopper where the raw materials are fed, and a barrel where the materials are heated and mixed. The mixed material is then pushed through the die, which gives the material its final shape.

How do WPC Profile Extrusion Machines Work?

The process of creating WPC involves mixing wood fibers with a polymer prior to extrusion. This new compound will retain some of the properties of wood while gaining added properties from the polymer. PVC, PE, and PP are the most commonly used plastics in WPC products.

The die is custom-made to produce a specific profile. The calibration table is utilized to ensure that the profile is the correct size and shape. The haul-off machine pulls the profile through the calibration table and cools it down. Eventually, the cutting machine cuts the profile to the desired length.

Key Components of WPC Profile Extrusion Machines

The WPC Profile Extrusion Machine comprises several key components, including a feeder, a twin-screw extruder, a profile die, a calibration table, and a cutter.

- Feeder

The feeder plays a crucial role in accurately measuring and delivering the raw materials to the extruder, which melts and mixes the materials together. To ensure an efficient production process, the feeder should be of high quality and have a consistent feed rate. - Extruder

The extruder is the heart of the machine, responsible for melting and mixing the materials together. It should have a high output capacity and be able to produce a consistent mix of materials. The twin-screw extruder is commonly used in WPC Profile Extrusion Machines, as it provides better mixing and melting capabilities. - Profile die

The profile die is the component that shapes the melted material into the desired profile. It should be custom-made to produce a specific profile and be designed to withstand high temperatures and pressures. - Calibration table

The calibration table ensures that the profile is the correct size and shape. It should be made of high-quality materials and be adjustable to produce different profiles. The table should also be able to cool the profile down quickly to avoid warping or deformation. - Cutter

The cutting machine is responsible for cutting the profile to the desired length. It should be able to cut accurately and consistently, with minimal waste. The cutter should also be easy to adjust to produce profiles of different lengths.

Versatile Production for Various Applications

WPC Profile Extrusion Machines are versatile equipment that can produce a wide range of profiles suitable for various applications. These machines can process different materials such as PVC, PE, PP, and WPC to create profiles that meet the specific needs of manufacturers.

One of the most common applications of WPC Profile Extrusion Machines is the production of PVC windows, doors, and ceiling panels. These profiles are durable, low-maintenance, and offer excellent thermal insulation properties. They are widely used in residential and commercial buildings due to their energy efficiency and cost-effectiveness.

Another application of WPC Profile Extrusion Machines is in the production of PVC/WPC wall panels. These profiles are lightweight, easy to install, and offer excellent acoustic properties. They are commonly used in interior wall cladding applications, providing a decorative and functional finish to any space.

Other profiles that can be produced using WPC Profile Extrusion Machines include PVC cable trunking profile, PVC corner bead, PVC edge banding strip, PVC imitation marble strip, and many others. These profiles have various applications in the construction, automotive, and furniture industries.

Factors to Consider When Selecting WPC Profile Extrusion Machines

When selecting a WPC profile extrusion machine, it is important to consider several factors. Production capacity, material compatibility, extrusion process, quality, cost, and technical support should all be taken into account. To start, choose a machine that matches your desired output and is compatible with the material and extrusion process. Next, look for high-quality, reliable machines from reputable manufacturers, balancing cost against long-term productivity and product quality. Lastly, select a supplier that offers technical support and after-sales service to optimize performance and quickly address any issues that may arise. By considering these factors, you can ensure that you select the right WPC profile extrusion machine for your needs, which can help improve productivity and product quality in the long run.

Read also : 6 Key Factors to Consider When Selecting WPC Profile Extrusion Machines

Partner with Chen Yu - The Leading WPC Profile Extrusion Machine Manufacturer

As a reputable manufacturer, Chen Yu offers a diverse range of WPC profile extrusion machines in various sizes and configurations to cater to your production requirements. Our machines are specifically designed to meet the demands of modern manufacturers who prioritize precision and consistency in producing high-quality profiles. We understand the importance of these factors and aim to deliver machines that exceed your expectations. Whether you need small-scale customized production or high-volume manufacturing, our machines are engineered to meet your unique needs.

By partnering with Chen Yu, you gain access to state-of-the-art equipment that guarantees seamless and efficient production. Our machines are built to minimize downtime and maximize output, allowing you to save valuable time and resources.

If you're looking to elevate your WPC profile production to the next level, please contact us today to learn more about our WPC Extrusion Machines and how we can help you achieve your production goals.

Article Source: https://www.chenyu.com.tw/en/news_i_Understanding-WPC-Profile-Extrusion-Machines.html

Established in 1991, CHEN YU PLASTIC MACHINE CO., LTD is a professional designer and manufacturer in plastic machinery field. With yearly experiences of design and manufacture in plastic industry as well as sophisticated machineries, CHEN YU constantly devotes on innovative R&D development to improve product quality to near perfection.

As a versatile manufacturer, CHEN YU is definitely capable of meeting various requirements from clients in the industry. The state-of-the-art high precision and efficiency automatic plastic machineries in competitive prices from CHEN YU provide satisfying options for clients’ procurement.

The superior machine quality, considerate customer service and international marketing network are all the factors to win many approvals for CHEN YU from the market. In the future, CHEN YU will keep forward as an innovative pioneer for plastic industry.