橡膠射出成型機

熱門訊息

TungYu: Leading the Charge Toward a Greener Future

TungYu's Innovative Solutions Shine at TaipeiPlas 2024. TungYu, a pioneer in advanced manufacturing solutions, is thrilled to report the resounding success of our participation in TaipeiPlas 2024. Our cutting-edge technologies and commitment to sustainability captivated audiences and solidified our position as a leading force in the industry.

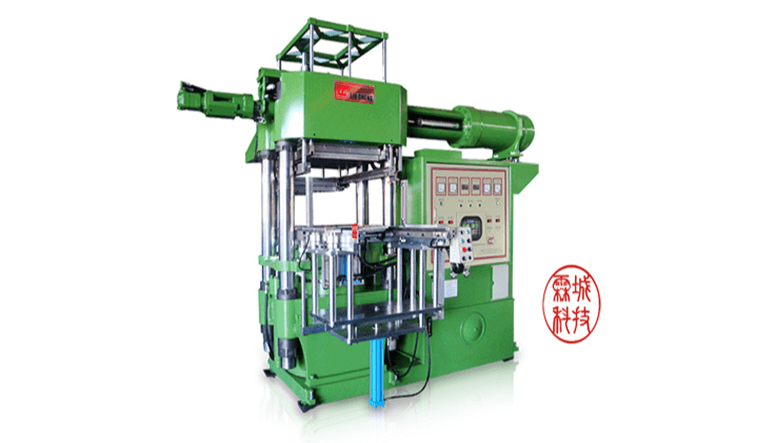

JingDay: A Pioneer in Rubber and Silicone Molding Technology, Forty Years of Expertise Yielding Diverse Applications

Rubber and silicone are no longer unfamiliar materials to most people. With their excellent elasticity, insulation, heat resistance, cold resistance, and outstanding electrical properties, it's easy to spot applications of silicone rubber in daily life. Since its establishment in 1983, JingDay Machinery, with its 40 years of knowledge and technology in rubber and silicone molding, has not only developed various specialized machinery for customers but also covered application fields such as automotive, motorcycles, 3C products, medical, sports products, and golf products.

Discovering Latest TungYu Solutions at 2024 Rubber and Plastics Exhibition

As part of its corporate development strategy, we will participate in the Global Rubber and Plastics Exhibition in 2024. This international exhibition brings together top companies and experts from the global rubber and plastics industries. Participation in this exhibition will provide TungYu with a platform to showcase its latest technology and products, engage in exchanges and collaborations with peers from around the world, and further enhance the company's international influence.

JING-DAY: Customized Rubber Injection Machines for Highly Specialized Applications

Research, mold making, and production can be considered as critical processes in rubber molding technology. Jing-Day Machinery, originating from Taiwan, has accumulated over 40 years of knowledge and expertise in rubber and silicone molding since its establishment in 1983. This expertise allows them to excel in crucial technologies, enabling them to develop various specialized machinery and equipment for clients across a wide spectrum of industries.

LIN CHENG: None Runner-Waste Rubber Injection Molding Machine

For more than four decades Lin Cheng Technologies has shown its great expertise around the world on creating exclusive services for customers. We stand out in the field for manufacturing rubber injection molding machines, silicon rubber injection molding, vacuum compression molding, thermoforming, thermosetting, carbon fiber molding, powder forming and other types of compression molding machines.

JING DAY: The Best Customized Rubber Injection Machines for Automotive Parts and Components

According to rubber industry studies, it is expected that the rubber injection machine market will have a moderate growth during the present time to 2027. This is due to the changes occurring in the market, such as: fast production of rubber products, minimum wastage of material, low labor cost, and flexibility in material, color, and design.

TungYu: Horizontal Rubber Injection Molding Machine

How to save material and increase productivity simultaneously? Horizontal rubber injection molding machine can contribute to reduce material waste and optimize automation. Tung Yu makes our effort to serve the best solution for customer.

What to Expect in 2022 for LIN CHENG’s Strategy and Performance for their Rubber Injection Molding Machinery

For more than four decades Lin Cheng Technologies has shown its great expertise around the world on the run of providing Customized Solutions, Rubber Injection molding machines, Silicone rubber injection machines, vacuum hot press injection molding machines and other types of hot press injection molding machines to the Industry.