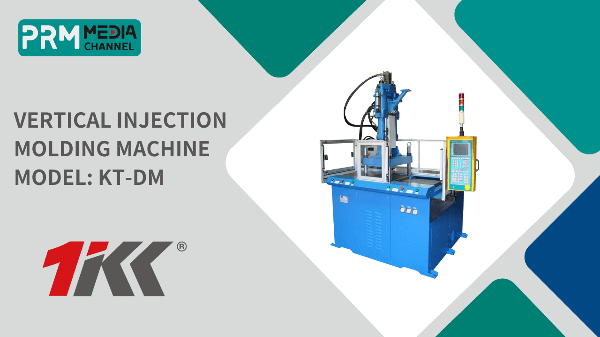

TAIWAN KINKI(TKC) is pioneer of Vertical Injection Molding Machines for Auto Industry, we were the first in the world to design and manufacture the 1st all-electric vertical injection molding machine for Taiwan and China. TKC works with a wide range of plastic injection materials and molded parts.

【All-Electric Vertical Injection Molding Machine Features】

Low Noise:All process-relevant movements (injection, mold open/close) are executed via electric motors, resulting in quieter and less noisy operation.

High Efficacy:The electric unit is digitally controlled so that the mechanical operation is highly repeatable and precise, and the electrical drive enables the parallel movement of the machine, so the process is faster and more efficient.

Save Water:Fewer components and oil need to be preheated than hydraulic injection machines, thus saving on cooling water usage.

Power Green Energy:No hydraulic system is used, and energy is only used during machine movement, so it can save more energy and achieve power green energy.

FEATURES:

1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions.

2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation.

3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production.

4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items.

5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects.

6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

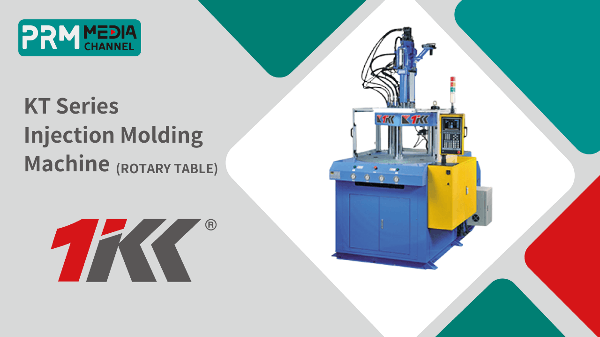

KT Series Injection Molding Machine

Vertical mold clamping and injection, small footprint and high degree of precision. This machine is ideal for injection of medium and small products with inclusions.

Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for production of thin items.

Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation.

Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects.

This machine offers a wide range of programmable functions including automatic inclusion, extraction and fully-automatic production.

There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

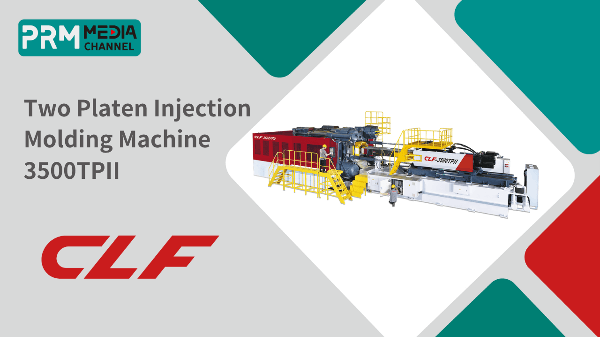

➡️ Maximum injection weight 34 KG.

➡️ High stability, High efficiency, High energy saving..

➡️ Electric Plasticizing Motor substantially increases production capacity and saves energy.

➡️ Direct pressure clamping to make the mold evenly stressed.

➡️ Smooth, stable and powerful.

➡️Uniform tension force on tie bars for dramatic increase of service life.

➡️Simplified construction with no wearing problem on toggle clamp.

Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc.

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety.

Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations.

When installing a Quick Mold Change System for your injection molding and mold casting operations there are a number of direct and indirect benefits. Review the following table to see an overview of all of these benefits.

Indirect Benefits

Die Standardization

Press Standardization

Increased Safety

Improved Working Environment

Increased Competitiveness

Direct Benefits

Reduction in Die Change Time

Efficient Small Batch Runs

Reduced Stock Handling

Higher Productivity and Quality

Reduction in Labor Costs

Livestream time: November 20th at 19: 00 (GMT +8, Taipei)

The Livestream that PRM Media Channel held with KING'S SOLUTION CORP. with the title of Plastic Injection Molding Innovations and Green Solutions brings you new insight into the injection molding machine industry. Remember to direct your questions in the live chat section, KING'S SOLUTION and PRM Media Channel will be replying to your questions.

What are the challenges, trends, and innovations in the injection molding industry? How to sustain after-sales services during post-pandemic? What advantages LPM (Low-Pressure Molding) brings to the manufacturers compared to Epoxy Injection Molding? Do you also have similar questions like that or would like to learn more? Then we welcome you to watch the Livestream video on November 20th at 19: 00 (GMT +8, Taipei)

【VIDEO OUTLINE】

00:00 Opening

00:59 KING'S SOLUTION CORPORATION

02:00 "Green Solution, Machine Soulmate" Slogan

03:04 Why to customize the machines?

05:00 Customized Machine Series

06:00 Market Challenges and Successful Cases

10:38 5 Gallon PET Preform Injection Molding Solutions

12:35 Advantages of KING’S in 5 Gallon PET Preforms

16:16 Trends in Injection Molding Market

18:40 LPM Application Examples

23:00 LPM Method vs Epoxy Method

26:00 After Sales Services and Customer Relations

28:55 Message to Current and Potential Customers

Know PRM Media Channel more on:

PRM Media Channel Website: https://bit.ly/3uqdubs

PRM Facebook: https://www.facebook.com/PRMMediaChannel

PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

【VIDEO FOCUS】: SHINI Industry 4.0 Smart Factory for Injection Molding which is called "sFactory 4.0"

【ABOUT SHINI】

Derived from Taipei, Taiwan, Shini group has gone through an extraordinary journey for more than 40 years. To date, Shini group has established six production bases and one corporate technology center globally. Specialized in manufacturing plastic auxiliary equipment, Shini products consist of eight series, including drying & dehumidifying, feeding & conveying, dosing & mixing, heating & cooling, granulating & recycling, automation solution, systematic solution, and hot runner system. Adhered to the management principle “focusing on a particular business, pursuing to be the world leader”, Shini people have created new situations one after another. Till now, Shini group has ranked among the world-class manufacturers of plastic auxiliary equipment and taken the lead of Asia's plastic auxiliary equipment industry.

【AUXILIARY EQUIPMENT IN THE VIDEO】 Hot Runner Temperature Controller-TC50 for Injection Molding Machines, IoT Solutions from ARICO.

【FEATURES】

HMI: 7" LCD display with touch panel

Group setup function

Mold Memory

Power balance detection and display

Synchronous heat up and cool down

Self-diagnosis log

Mold leakage detecting

Injection machine connect for I/O function

VNC function(option)

【SPECIFICATIONS】

Thermocouple type: J/K

Temperature unit: ℃/℉

Heating mode selectable

The maximum drive current is 15 ampere for each zone

Temperature PID control

Zero cross/Phase angle output trigger modes

Auto detect the frequency of power source

The current detect and display

The output with auto/manual setting

The soft-start for dehumidification

Boost

Standby

Output mode: Stop/Manual/Slave/continually selectable when Thermo-coupler broken

Overload protection for electric Overload protect for heating output

The protect mode of power source when wrong input

Auto shutdown when abnormal work on the module

The fast fuse used to protect TRIAC

【ABOUT ARICO】

ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. Founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. ARICO is not only good at producing customized precision Hot Runner Temperature Controllers and related application equipment but also provides high-quality Hot Runner Temperature Controllers with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia, and other countries.

【ASSEMBLING VIDEO】

Two Platen Injection Molding Machine 3000TP from CLF.

CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance.

MACHINERY IN THE VIDEO: Rotary Table Injection Molding Machine with Full Auto System from TAIWAN KINKI (TKC)

[TAIWAN KINKI LINES OF BUSINESS]

Production of vertical plastic injection molding machines.

Design of automatic injection molding machinery.

Turn-key plants for accessories and peripherals for injection machinery.

Injection mold design and manufacturing.

Electrodeposition, powder coating, baking enamel, and leather treatment.

Agency of the vertical injection machine and Zinc alloy coating.

[APPLICATIONS]

Especially suitable to manufacture Automobile Parts

[TAIWAN KINKI (TKC) BACKGROUND]

TKC had over 40 years of experience in Vertical Injection Molding Machine manufacturing.

The company offers a full series of vertical injection molding machine portfolios including Standard, Slide, and Rotary table models. TKC also offers mold design and a full auto system for customer's products.

Two Platen Injection Molding Machine 600TPIIR 3D animation from CLF.

CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance.

【HIGHLIGHTS OF THE MACHINE】

Clamping Force 1800~4000 TONS

Unique two-platen design for clamping mechanism exhibits exceptionally high-speed clamping feature.

Clamping force, mold opening stroke, and distance between tie bars are easy to customize.

Quick and accurate mold adjustment makes the machine suitable for small lot flexible production.

Uniform force distribution on mold ensures the high accuracy of the product.

Uniform tension force on tie bars for the dramatic increase of service life.

Simplified construction with no wearing problem on toggle clamp.

Rigid machine structure, minimum deformation, and consistent product accuracy.

MACHINERY IN THE VIDEO: Vertical Injection Molding Machine -Rotary Table KT 300R 3S

FEATURES:

-Vertical mold clamping and injection, small footprint, and high degree of precision. This machine is ideal for the injection of medium and small products with inclusions.

-The Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items.

-Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation.

-Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects.

-This machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production.