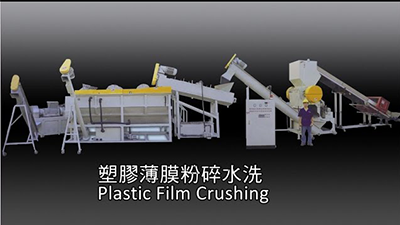

Plastic Washing Machine - Plastic Film Crushing Washing and 3IN1 Pelletizing Line - Waste Plastic Crushing & Washing Line 1000kg - GEOR-DING MACHINERY CO., LTD..

We specialize in manufacturing of Plastic Washing Machine. The main businesses include: Plastic Washing Machine and planning of entire plant’s equipment. While the demand for output and quality in Plastic Washing Machine worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Plastic Washing Machine products and services to higher standards.

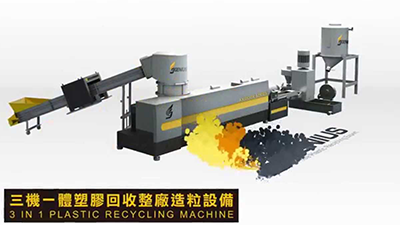

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

Specializes in waste plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in waste plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our waste plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world.

Product Feature:

-Drive-train: High torque gearbox made with precision grinding. Low noise, steady and smooth operation.

-Low power consumption, high output.

Dedicated screw and barrel design: According to the characteristics of recycle materials, dedicated screw is designed to completely impurities such as water and bad air; the screw also has a variety of advantages, for examples, good mixing, good dispersion, high output, and others. Die head pelletizing eliminates the labor cost on batter brace. No water tank. Consumes less space.

Extruder is equipped with pressure sensors. When there is excessive pressure, warning light or buzzer send notification for replacing filter screen. No need to shut down the machine when replacing the filter screen. Single extruder suitable for cleaner material pellets such as injection leftovers, edge trim.

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine - GEOR-DING MACHINERY CO., LTD..

We specialize in manufacturing of 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine. The main businesses include: 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine and planning of entire plant’s equipment.

While the demand for output and quality in 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine worldwide is increasing day by day, our determination for upholding the motto, "Quality is number one. Output comes second.

Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine products and services to higher standards.

Vacuum Molding Machine - Oil Seal Vacuum Molding Machine- LIN CHENG

Specializes in Vacuum Molding Machine, Lin Cheng Technologies Co., Ltd. was established in 1978 and has a strong professional team to manufacture Vacuum Molding Machine. A series of services we can provide ranges from the purchase of machines to the design and development of molds. Our Vacuum Molding Machine products are used for electronic components, car parts, oil rings, and so on. In 1997, we were granted the ISO 9002 quality certification.

Plastic Recycling Machine -Genius- Plastic film squeezing machine Specializes in plastic recycling machine,

GENIUS MACHINERY CO., LTD. was established in 1992, professional in plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world.

The latest solutions for film washing line If you would like to produce the high quality and validity of pellets, you beware "Squeezing process must be prior to pelletizing process". After plastic recycled film materials are washed, the moisture is usually retain over 30%. Therefore, our superior design team specially developed a squeezer to meet customers’ needs.

Through this machine, water and volume of the materials can be squeezed to increase the quality of the pellets and the efficiency of the extruders. Speed-changing gearbox We adopt a self-made gear box with high technology precision. Our single screw squeezer is equipped with a gearbox with two-speed derailleurs.

According to characteristics of the materials you feed, you can choose which speed you want. You don’t need to buy another squeezer when you feed another kind of materials. It makes the whole washing line more efficient and saves much space. High Productivity Through our dedicated screw design, washed materials can be squeezed to dehydrate water of films or fluffy stuff. The recycled materials you feed are squeezed to become flakes or lumps .

The moisture they contain will be lowered down to 1-3%. After being squeezed, these lumps or flakes with much lower moisture and higher density can be directly fed into pelletizing extruder. Its output can amount to 700~960kg/hr per hour and the degradation of the pellets will be highly decreased. Furthermore, you don’t need to increase heating rate. The quality and validity of the pellets and the efficiency of the extruder will be improved with the increased capacity. Always your best choice Our single screw squeezer can help you SAVE cost, SAVE energy, SAVE time, PROTECT environment, and INCREASE productivity as well as efficiency. It is definite your best choice! You NEVER miss it.

MACHINERY IN THE VIDEO: Vertical Injection Molding Machine -Rotary Table KT 300R 3S

FEATURES:

-Vertical mold clamping and injection, small footprint, and high degree of precision. This machine is ideal for the injection of medium and small products with inclusions.

-The Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items.

-Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation.

-Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects.

-This machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production.

5G PET Preform Turnkey - 5 Gallon PET Preform Injection Molding Machines & Whole Plant Turn-Key Solution-pet-King's Machinery.

FEATURES Select from 2, 4 or 8 cavities mold specifications.

Single mold, 4 cavities design. The 2 stage material feed system raises the repeatability rate, lowers the cycle time, and boosts performance.

When combined with a secondary cooling system, performance can be doubled.

Temperature control via TSR raises temperature accuracy and, working with the accumulator, increases injection speed.

Unique economical design is twice as energy efficient as comparable commercial units.

we offer a complete set of 5 gallon PET bottle manufacturing equipment: raw material dehumidification and drying system; fixed-volume color additive; quickly stabilizing PET bottle preform molding machine; 4 cavity, hot runner mold; rapid cooling robot; and bottle blowing machine. From raw material to finished product stages, this all-inclusive system promotes high productivity, low cost, and superior quality-the bottle blowing defect rate is kept to a minuscule 0.5%.

When water is shortage and lack of quality sanitary sewer, therefore, water container or bottle is convenience to filling in clean water and to carry with to the public. Moreover, bottle is not only for water-use but also oil-use even other liquid-use.

King's gallon-size pre-form is one of the best choices in worldwide. Not only does save 20% of shipping cost but also decrease defect of blowing rate down to less 0.5%. And the most critical point is that any color is so clear by King's latest technology and 20 years PET knowledge.

Continuous Plastic Thermoforming Machine For Cup Lids | SL-1220A from CHUDONG MACHINERY

High-rigidity design of machine bed:

Integral casting design combined with high-tension steel plate structure offers steady and low noise operation.

4-column high-rigidity guide-rod mechanism:

Guide-rods are made of top-grade steel, offering high repetitivity of mold clamping in combination with the 4-column mold structure for steady forming.

Servo chain feeding system:

Japanese chain operated by servo-controller ensures exact precision of high-speed feeding.

Precision Temperature Control System:

Independent temperature control with the respective settings for each temperature zone uses SSR with PID calculus for controlling the temperature, combined with high-speed transmission and control, offers precision adjustment, and is convenient for elevated yield.

Upper and Lower Heating Oven:

German-made ceramic heater, temperature accuracy can be controlled very well.

Automatic Lubrication System:

Automatic oil feed for slide parts, eliminating any failure resulting from insufficient lubrication.

Applications:

Disposable Sushi box, egg tray, Various types of lids, Cooked food coverings, Strawberry box, Salad box, Plastic containers, Transparent salad containers, Fruit box, Vegetable box, Fresh fruit packaging, All types of food packaging, Takeout box, Instant noodle bowl, Lunch box, and so on

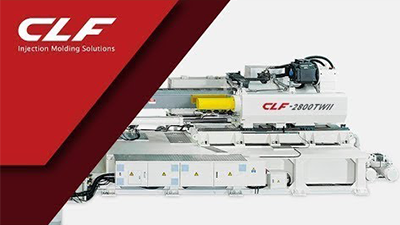

Injection Molding Machine - Chuan Lih Fa

Specializes in injection molding machine, CHUAN LIH FA MACHINERY WORKS CO., LTD. was founded in 1966, backed up with 40 years manufacturing injection molding machine, multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer experience.

CLF Supply maximum injection machine machine all over the world. Precisely productive equipments and rigidly productive procedures have providing customers with satisfied multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer quality to help them getting most profit.

Plastic Thermoforming Machine for Fruit Container Box - RMD 800from CHUDONG MACHINERY

European design, intelligent control, lightweight.

Convenient mold change, quick, suitable for smaller quantities and diverse production line manufacturing.

High rate of movement, low failure rate, reducing the costs associated with machine errors.

Innovative intelligent system, which gives the operator an easy to use interactive interface which reduces the opportunity for human error.

Remote obstacle monitoring and instantaneous data processing allow rapid problem correction.

High-precision cutting technology, allowing high-speed control, low machinery wear, and exceptional cutting performance.

Adjustable, automatic stacking technology, which remembers your last production needs.

Applications:

Disposable Sushi box, egg tray, Various types of lids, Cooked food coverings, Strawberry box, Salad box, Plastic containers, Transparent salad containers, Fruit box, Vegetable box, Fresh fruit packaging, All types of food packaging, Takeout box, Instant noodle bowl, Lunch box, and so on

Injection Molding Machine - Chuan Lih Fa

Specializes in injection molding machine, CHUAN LIH FA MACHINERY WORKS CO., LTD. was founded in 1966, backed up with 40 years manufacturing injection molding machine, multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer experience.

CLF Supply maximum injection machine machine all over the world. Precisely productive equipments and rigidly productive procedures have providing customers with satisfied multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer quality to help them getting most profit.

All Electric Injection Molding Machine

Features:

⚫Electricity Regeneration Circuit Electricity Saved by 15%

⚫Employs German Siemens control and servo motors for excellent performance and high accuracy.

⚫High performance injection unit that enhances the exceptional features of servo control.High speed,stability and accuracy are guaranteed.

⚫In-house software development capability combined with technical support from Siemens.

⚫Standardized hardware design simplifies the maintenance works and reduces the spare parts stock.

⚫Simultaneous control on multi-axes shortens molding cycle time dramatically.

⚫Overall super rigid structure minimizes running vibration.

⚫Exclusive energy-regeneration function not only provides electricity-saving and environmental protection, but also meets today's trend of energy-saving.

⚫Ergonomics operation interface.

⚫The access level to controller management can be ranked.

⚫Rigid platen design exhibits superior parallelism.

⚫Supports remote monitoring functions.