近期更新

2023 IPF 孟加拉展廠商採訪 | POLYSTAR 世林

很開心邀請到世林機械的 Sumit 來分享疫情後孟加拉工業的變化以及和印度市場的不同之處。在塑膠用料的需求增加的情況下,回收也是相當重要的一環。他也提到政府如何因應環保議題來實施相對應的措施。

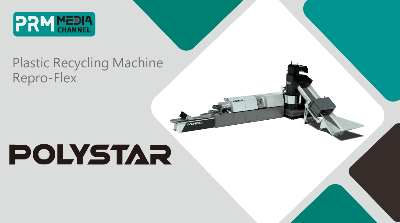

Plastic Recycling Machine, Repro-Flex | POLYSTAR

【Machine Features】 The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line. The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption. Simple in Design. Flexible in Operation. POLYSTAR is able to customize its machines regarding customers’ needs. How this pelletizing system works: 1. Feeding a. By belt conveyor Feeding of scraps is easy and automatically controlled depending on the amount of material input. b. By Nip roller Film-on-rolls can be fed at the same time. 2. Cutting and compacting The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. 3. Degassing system The two-zone degassing can process plastic film with larger printed areas. 4. Filtration Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking. 5. Pelletization Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head. 6. Final Product Round-shaped recycled pellets are produced and cooled inside the water ring immediately. 【Company Intro】 Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

Twin Head Blown Film Machine for Plastic Bag Manufacturers | POLYSTAR

Introducing POLYSTAR Twin Head Blown Film Machine with the motto of the company: "Extrusion Made Simple". The blown film extruder is specially designed for HDPE and LDPE bag producers. 【HIGHLIGTS OF Twin Head Blown Film Machine】 - Monolayer (1 Layer) - Two Die Heads, Single Screw - Film Width from 150~650mm - Extruder Dia: 45mm, 55mm, 75mm - Material: HDPE, LDPE - Output: 30~140 kg/hr - Works with virgin, recycled materials, Biomaterials, and CaCO3 - Possible end products: T-shirt bags, Bottom sealed flat bags, Shopping bags, Supermarket bags, Garbage bags 【MACHINE PORTFOLIO OF POLYSTAR】 1. BLOWN FILM MACHINES - One Layer Twin Head HDPE LDPE 650mm Machine - Multilayer Blown Film Machines - One Layer HDPE / LDPE 800mm (Mini type) Machine - AB - 2 Layer Co-Extrusion LDPE/LLDPE Machine - One Layer HDPE LDPE LLDPE 1500mm Machine 2. BAG MAKING MACHINES - Bottom Sealing Bag Making Machines - Folded Garbage Bags Machines - Perforated Bag on Roll Machines - Thick Bag Making Machines - Laundry Bags Machines 3. RECYCLING MACHINES - Plastic Recycling Machines - Plastic film recycling Machines - Two stage recycling Machines - Air cooled recycling Machines - Hopper feeding recycling Machines - Shredder integrated recycling Machines 【ABOUT POLYSTAR】 POLYSTAR is a pioneer manufacturer of Plastic Recycling Machines, Blown Film Extruders, and Plastic Bag Making Machines. The company has gained the trust of its customers with 32 years of experience in the industry, today POLYSTAR has been sold over 4,000 machines in 105 countries worldwide.

Turkish Plastic Market Evaluation | PDA GLOBAL Interview (POLYSTAR Agent)

PRM Media Channel continues to share with you the most current industry insight into local markets around the world. This time our guest of PRM Industry Insight program is Mr. Emrah Cakir from PDA GLOBAL company, as well as the agent of POLYSTAR in Turkey. We have touched on many current topics of the plastics machinery industry including the shipping obstacles, current plastic packaging machinery demand of the Turkish market due to emerging needs, advantages of having a local agent in the Turkish market, the fluctuation in the foreign currency in the Turkish market, and so on. Let's take a look at the video and hear more from Mr. Cakir about his solution suggestions to the current issues in the market. Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan