影片介紹

【Machine Features】

The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line.

The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption.

Simple in Design. Flexible in Operation.

POLYSTAR is able to customize its machines regarding customers’ needs.

How this pelletizing system works:

a. By belt conveyor

Feeding of scraps is easy and automatically controlled depending on the amount of material input.

b. By Nip roller

Film-on-rolls can be fed at the same time.

2. Cutting and compacting

The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

3. Degassing system

The two-zone degassing can process plastic film with larger printed areas.

4. Filtration

Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking.

5. Pelletization

Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head.

6. Final Product

Round-shaped recycled pellets are produced and cooled inside the water ring immediately.

【Company Intro】

Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today.

Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

-

Plastic Recycling Machine - Plastic Film Squeezing Machine | GENIUS

Plastic Recycling Machine - Plastic Film Squeezing Machine | GENIUS

-

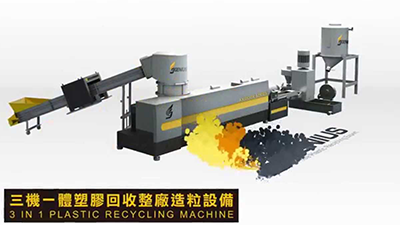

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

-

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

-

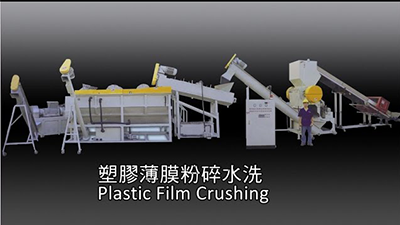

Plastic Washing Machine | GEORDING

Plastic Washing Machine | GEORDING

-

Twin Screw PVC Pelletizing Line | TWIN SCREW

Twin Screw PVC Pelletizing Line | TWIN SCREW