High Speed Slitting Machine - S2A Series | YICHEEN

YICHEEN is a professional equipment supplier that specializes in soft-material cutting technology, including die cutting, sheet cutting, slitting and laminating. Since 1979 we have been supplying soft material cutting machinery. This has now transformed into state of the art high-precision customized cutting equipment, which meets worldwide standards and guidelines.

CHINAPLAS 2021 Organizer Interview | PRM Media Channel

Recently despite many exhibitions that have been canceled or postponed, CHINAPLAS 2021 successfully made the event to be held on time, April 13th to 16th, 2021. In this manner, PRM Media Channel has conducted an online interview with Ms. Ada Leung, the General Manager of Adsale Exhibition Services Ltd., the organizer of CHINAPLAS. Ms. Ada Leung sincerely replied to our questions about this special event at a special time due to the pandemic. She also shared very useful information about the forthcoming CHINAPLAS 2021 including the focus of the exhibition, online activities for the visitors who cannot attend the exhibition, future plan of CHINAPLAS through digitalization and hybrid exhibition model. Let's take a look at the interview video to learn more, and let us know your opinions and questions.

2024 CHINAPLAS Interview | JANDI’S

We are here with Tony from JANDI’S at the CHINAPLAS. JANDI’S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag-making, printing, and recycling machines. They obtained more than 30 patents for plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI’S proposes an idea about green innovation. The company develops JIT series integrated plastic bag-making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI’S added the automatic packaging part to JIT series.

Twin Screw PVC Pelletizing Line | TWIN SCREW

We are a pioneer of twin screw extruder. Description: TWIN SCREW EXTRUDER ⚫With two parallel counter-rotating screws for the palletizing. ⚫Reduction and torque-distribution unit with hardened, ground shafts and gear. ⚫Long service life for the processing units due to lower specific drive energy. ⚫Increased process reliability due to modern control technology. ⚫Easy maintenance and service. DIE FACE CUTTING ⚫Hinge flange type. ⚫High speed rotation of the knives. ⚫Continuous production of granulate. VIBRATION COOLER ⚫Up & Down two vibrating bed. SILO TANK ⚫Stainless steel. Our Service: Technology innovation, perfect service, and internationalization are always our core values, with this mission we have become the pioneer of twin screw extrusion in the global market and a reliable partner of our customers. TwinScrew will never stop progressing in the field of PVC extrusion and twin screw extrusion; we will no doubt lead the twin screw technology into an ultimate and great attainment.

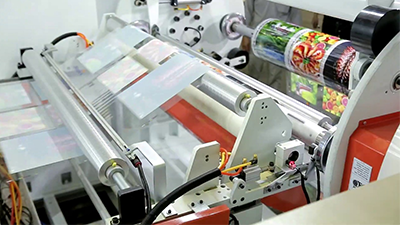

Shrink Sleeve Conversion Seaming Machine - K5 Plus | WEBCONTROL

Machine Specification - WEBCONTROL Seaming Machine K5 Plus: -Machine Speed: 500 m/min -Width: 350 mm -Material Width: 720 mm -Unwind Diameter: 600 mm (Option 800 mm) -Rewind Diameter: 600 mm -Minimum Lay Flat Width: 40 mm with 18 mm option -Core Diameter: 3" (76 mm) -Lay Flat Tolerence: 0.25 mm The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. WEBCONTROL has once again innovated by launching the third generation of seamers which eliminates the forming tool. This new patented design makes the K5 PLUS the most operator friendly machine available, facilitating operator training with the most automated machine on the market. The K5 PLUS has 3 tension zones, which allows for a dedicated tension zone in the forming section for better layflat control. The unwind tension zone is now free to add innovations like laser integration for t-perforation or pin hole perforation while the film is flat. The K5 PLUS offers a long list of advantages that solve the issues that come with the previous generation of machines that use forming tools. This new machine promises to revolutionize the way shrink sleeves are converted. Make sure you see it before making any decisions.

Haitian Mexico Interview Part 2 | Solutions for Pandemic and Future Outlook

At the beginning of the month, we had a video conference with one of the greatest Injection Molding Machine Industry from Mexico, Haitian Mexico! In Part 2 of the video conference the Deputy General Manager of HAITIAN MEXICO, Jose Antonio Barroso, talked about the challenges they are having due to the pandemic, their solutions to overcome those challenges, and the current situation of COVID-19 in Mexico.

2023 IPF 孟加拉展廠商採訪 | POLYSTAR 世林

很開心邀請到世林機械的 Sumit 來分享疫情後孟加拉工業的變化以及和印度市場的不同之處。在塑膠用料的需求增加的情況下,回收也是相當重要的一環。他也提到政府如何因應環保議題來實施相對應的措施。

Seaming Machine | WEBCONTROL

Seaming Machine - Webcontrol Purpose of Machine : For Shrink sleeve. Features -Stable and heavy-duty frame for high speed operation of 300 m/min. -Adjustable forming plate creates efficient operation. -Auto solvent feeding control. -Auto tension control for unwind/rewind unit to maintain the optimun tension. -Accurate product width. -Cantilevered rewind/unwind shaft for fast roll changeover. -PLC with color touch screen control system. -Rewind oscillation control to produce high quality rolls.

Five Layer Blown Film Line | Multilayer Blown Film Machine | Blown Film Extruder - Kung Hsing

/ Kung Hsing Main Products / K.S. manufacture Agricultural Blown Film Machine, Inflation making machine, Flat Yarn making machine, Plastic strapping band making machine, Plastic Recycling Machine, as well as special design for all extrusion system machineries and whole plant projects. #KUNGHSINGPLASTICMACHINERY #BLOWNFILMLINE #MULTILAYERBLOWNFILM

Hydraulic Die Cutting Machine (HDR 0505) | Yicheen

Yicheen specializes in manufacturing Rewinding Hydraulic Die Cutting, which high speed sliding table feeding, motion is fast and safe.

2024 NPE Orlando Interview | WIPA

We are honored to have our first interview with Wipa, a high-quality plastic recycling machine manufacturer from Germany. In this interview, Wipa introduces their latest machine show at NPE, highlighting its features and benefits for the plastic recycling industry. Join us to learn more about this innovative technology and how Wipa continues to lead performance.

Quick Mold Change System | FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

Exploring the Future of Plastics Industry with Juan Eduardo Zarate | 2025 PLASTIMAGEN Interview

What’s next for the plastics industry? At 2025 PLASTIMAGEN, PRM-Taiwan interviews Juan Eduardo Zarate to uncover key insights into this year’s exhibition! Interview Highlights: How big is PLASTIMAGEN 2025? Discover the scale and number of exhibitors at this leading plastics event. Celebrating 25 Years: Special activities marking the 25th anniversary of PLASTIMAGEN! ESG & Sustainability: Plastics remain essential—how can we improve recycling and promote sustainability? ???? Subscribe to PRM-Taiwan for exclusive industry insights!

All-Servo Drive T Shirt Bag On Roll Bag Making Machine ft. Swing Type Feeding System | PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

Escalation of Industry 4.0 in Plastic Machine Industry | PRM What to Say EP8

Escalation of Industry 4.0 in Plastic Machine Industry | PRM What to Say EP8 Nowadays, everything has been advanced to automation and connection to the Internet. Even in the Plastic and Rubber Industry, which we might consider as the traditional industry, it has been upgraded gradually through the industry 4.0 revolution. Let’s take a quick look to understand what are Industry 4.0 and IoT, and how does the Plastic and Rubber Industry apply it. Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

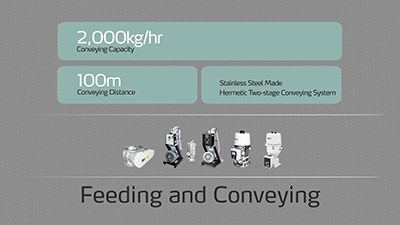

Plastic Dryer, Hopper Loader, Gravimatric Blender | SHINI

Plastic Dryer, Hopper Loader, Gravimatric Blender - Products Overview -Shini Specializes in plastic dryer and hopper dryer. SHINI PLASTICS TECHNOLOGIES, INC. products including hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chillers, sprue picker, side entry robot,gantry robot and more. The Shini Group, Originate from Taipei, Taiwan since 1969. Five manufacturing bases and one corporate technologies center around the world. World class manufacturer of plastics auxiliary equipment. For 41 years, Shini people adhered to the management principle of Focusing on Particular Business, Pursuing to be the World Leader which created new era and achieved many progresses. Shini Group has now become a world-class manufacture of plastic dryer, hopper dryer, hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chiller, sprue picker, side entry robot, gantry robot.

2024 NPE Orlando Interview | ZERMA

In our first interview with Zerma, we had the pleasure of speaking to CEO, Max Paeslack about the innovative shredder they brought to NPE. Significantly, they also reveal the strategic reasons behind the decision to shift their development focus to Shanghai, China.

Corona Treater | CHAANG HORNG-

.For non-conductive substrates .400~1600mm treat width available .One / Two side treatment .25mm segmented electrode finger .Φ 2.5” treatment roller

2024 NPE Orlando Interview | ISI

I had the pleasure of meeting Mr. Joe Whann at NPE Orlando. Joe is not only brilliant but also incredibly friendly! He provided an insightful introduction to the wide range of services offered by ISI and shared how they have become a leading agent in the USA. Don't miss out on learning about their impressive journey and expertise!

2024 CHINAPLAS Interview | ARBURG

I'm honor to meet Dr. Christoph Schumacher, the vice president Global Marketing from Arburg. Let's hear about what's his thoughts on Chinaplas! And their new type machine launched in China.

Two Platen Injection Molding Machine 600TPIIR | CLF

Two Platen Injection Molding Machine 600TPIIR 3D animation from CLF. CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance. 【HIGHLIGHTS OF THE MACHINE】 Clamping Force 1800~4000 TONS Unique two-platen design for clamping mechanism exhibits exceptionally high-speed clamping feature. Clamping force, mold opening stroke, and distance between tie bars are easy to customize. Quick and accurate mold adjustment makes the machine suitable for small lot flexible production. Uniform force distribution on mold ensures the high accuracy of the product. Uniform tension force on tie bars for the dramatic increase of service life. Simplified construction with no wearing problem on toggle clamp. Rigid machine structure, minimum deformation, and consistent product accuracy.

ChenHsong CFO Dave:Technology Innovations and Market Insights in Turkey | PlastEurasia Istanbul 2024

At PlastEurasia Istanbul 2024, ChenHsong CFO Dave discusses the company’s long-standing presence in the Turkish market and their latest technological innovations. Dave shares insights on the newest machines domestrate at the event and offers expert views on market direction and industry trends, particularly in the Turkish and regional plastics markets. Watch to learn about ChenHsong's cutting-edge technology and the future of the industry. Like, share, and subscribe for more industry insights!

High Speed ELS Rotogravure Printing Machine | WORLDLY

High-Speed ELS Rotogravure Printing Machine WRP-HHI-1300-10C series | WORLDLY Machine Specifications - Max machine speed: 350 m/min - Web width: 1000 / 1200 / 1300 mm - Printing cylinder circumference: 350 - 900 mm - Material diameter: 800 / 1000 mm - No. Color: 10 colors

Extrusion Blow Moulding Machine |FONG KEE

Extrusion Blow Moulding Machine - High Speed Blow Moulding Machine-hbb-ssg-Fong Kee Specializes in Extrusion Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Extrusion Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Extrusion Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.

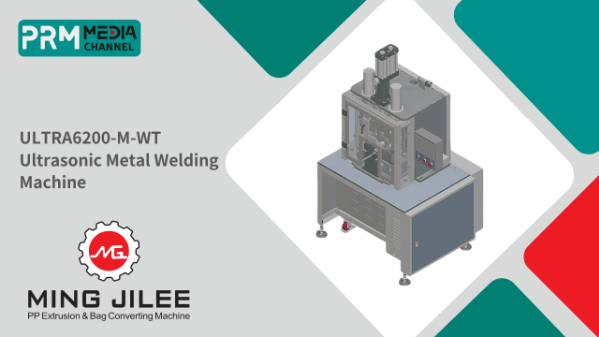

超音波金屬熔接機 / 超音波金屬焊接機, ULTRA6200-M-WT

超音波金屬熔接機 / 超音波金屬焊接機, ULTRA6200-M-WT Ultrasonic Metal Welding Machine 銘機實業股份有限公司 超音波自動化設備製造機, 創立於1987 台灣製造,最好的品質以及團隊服務

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6 Are you still seeking appropriate suppliers under the unstable circumstance of COVID-19? We heard your concerns and heartfelt wishes for attending an online exhibition! Through PRM Theme Pavilion, without traveling abroad, you will have many opportunities to connect with the world. Now, we are excited to announce an upcoming new event PRM Theme Pavilion, which will bring you to the new horizon. In this video, we are gonna present what you will see in this online exhibition. This time, we will focus on showcasing manufacturers who are specializing in the packaging industry. Let's take a look at the PRM What to Say episode 6, where we are evaluating and introducing the next PRM Theme Pavilion which focuses on the Packaging industry. In the video, you will learn more about not only what this event is about, but also the benefit of the event for global visitors, how the event is planned and concentrated on a specific focus with the selected machine manufacturers and machinery lines that a packaging business all need.

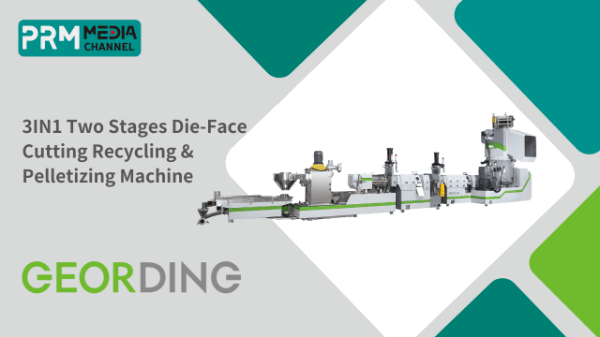

Side Entrance Two Stages System | GEOR DING

Side Entrance Two Stages System - Side Entrance Two Stages Die-Face Cutting Recycling & Pelletizing Machine GEOR-DING MACHINERY CO., LTD.. - Manufacturer of Side Entrance Two Stages System and more. We specialize in manufacturing of Side Entrance Two Stages System. The main businesses include: Side Entrance Two Stages System and the planning of the entire plant’s equipment. While the demand for output and quality in Side Entrance Two Stages System worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Side Entrance Two Stages System products and services to higher standards.

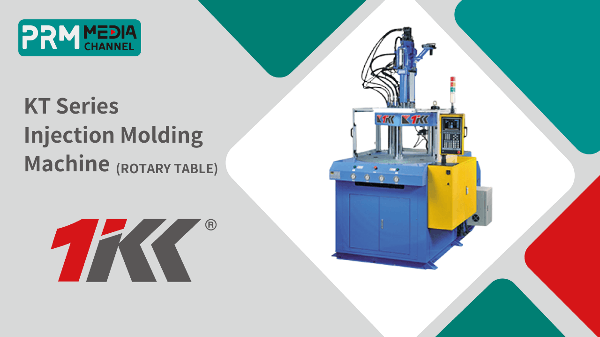

KT Series Injection Molding Machine (ROTARY TABLE) | TAIWAN KINKI

KT Series Injection Molding Machine Vertical mold clamping and injection, small footprint and high degree of precision. This machine is ideal for injection of medium and small products with inclusions. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for production of thin items. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. This machine offers a wide range of programmable functions including automatic inclusion, extraction and fully-automatic production. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

The Most Reliable PP/PE/PET Woven Bag Machinery Maker | HAO YU

Hao Yu Precision Machinery Industry Co., Ltd. is a leading manufacturer of PP/PE/PET woven bag machinery and whole-plant equipment. Since its establishment in 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence of HAO YU machines. Our objective is to enhance our present machinery and develop new models that improve the efficiency, product quality and profitability for our customers.

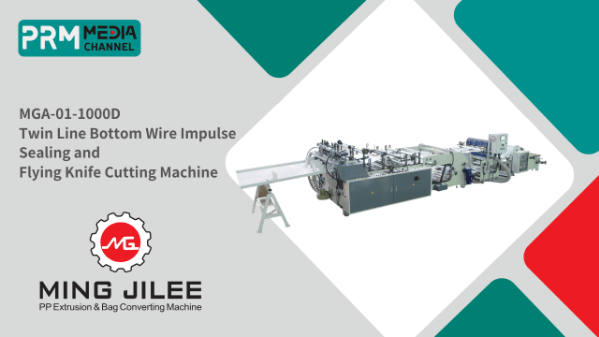

Twin Line Bottom Wire Impulse Sealing and Flying Knife Cutting Machine MGA-01-1000D | MING JILEE

Twin lines Bottom Bag impulse sealing and flying knife cutting machine, MGA-01-1000D

Bottle Grade PET Bottle Washing Line | BoReTech

MACHINERY LINE IN THE VIDEO: Bottle-to-Bottle Grade PET Bottle Washing Line from BoReTech. The line is mainly used for PET bottle-to-bottle projects (FDA Approval), which recycles post-consumer PET bottles into rPET flakes. The regenerative PET flakes conform to the quality index requirements of downstream food packaging and are used for bottle blowing and packaging which can directly contact food after pelletizing and SSP processes in the late stage. HIGHLIGHTS Solutions for diversification of input PET bottle bales. Automatic de-baling technology, reduces labor, a strong bale breaking ability for high-density PET bottle bales. Patent technology for PVC label removal. Patented Pre-washing and hot washing process to ensure the cleanliness of rPET flakes. Integrated technology and capability for automatic sorting machine and PET bottle recycling line. The hot washing process reduces impurities content to achieve food-grade index. Stable and reliable quality of rPET flakes, online inspection to ensure the stability of rPET flakes. Completed online water recycling treatment system for pre-washing, hot-washing, and rinsing. Low operation breakdown, production management guidance service for the customers. FOOD GRADE PET BOTTLE RECYCLING PROCESS De-baling➜Metal Removal➜Label Removal➜Metal Removal➜Bottle Pre-washing➜Optical Bottle Sorting➜Manual Sorting➜Crushing➜Dust Removal➜FlotationHot washing➜Friction Washing➜Rinsing➜Flushing Washing➜Drying➜Dust Removal➜Optical Flakes Sorting➜Blending➜Online Inspection➜Packing FOLLOW PRM ON: PRM YouTube:https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/ #BoReTech #PRMMediaChannel #PETrecycling #PETwashingLine #BottleToBottleRecycling #PRMTAIWAN #Plastics #Rubber #Industry #Internationalmarket #Export #machinery #PET #PETbottle #Recycling

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W | MING JILEE

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W For Further information:https://www.mingjilee.com/en/product/Wire-Impulse-Bottom-Bag-Sealing-Machine-with-Flying-Knife-Cutter.html

Circular Loom Machine - 6 Shuttle Circular Looms | HAO YU

Introducing 6 Shuttle Circular Looms Machine from HAO YU. With HAO YU HY7-m6SCL six shuttles circular loom is designed with 6 shuttles to perform tubular weaving at high speed up to 180 RPM which is the highest technology in this woven bag equipment field in Asia. It reaches outputs up to 140 meters per hour. In case warp and weft breaks (finished), the machine stops automatically, An auto compensation system is also equipped to prevent the machine from empty weaving, it is an advanced circular loom specially designed to meet the stringent productivity requirements of today. The circular looms equipped with European inverter and high quality components. HAO YU is applying patent in Taiwan, China, India, and other countries. 【Machine Features】 Low spare part consumption & easy maintenance Energy saving nearly 50% over conventional models Large weft yarn insertion capacity up to 1080 PPM(max) Flat yarn applicable weaving denier from 500-1200(standard) Large weft yarn carriage capacity up to 115mm(max) Equipped with European inverter for main motor Lubrication-free for shuttle & cam 【Optional Accessories】 Gusseting device Both sides heat slitting device and additional fabric winder Center unfold device with heat slitting device and extra large unwinder for cement bag industry 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

Brief Intro of Plastic Recycling & Pelletizing Machine | GEORDING

【Product Line】 Plastic recycling machine Compounding machine Dyeing & Pelletizing Automatic batch weighing and mixing system Washing line Rubbing drying machine Powerful crusher Shredder Plastic flat board extruder Refuse derived fuel (RDF) 【Company Intro】 GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well.