台北包裝展 2023 | PRM 帶看展

TAIPEIPACK 台北包裝展|PRM-TAIWAN 萬眾矚目的台北包裝展來囉! 無法來現場參與的夥伴們,別擔心! PRM這次也為大家準備了帶看展的節目 帶大家一睹展場的熱鬧氛圍!

Triangle Folding Machine & 1 Color Rotogravure Printing Machine | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000, MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT Originated from the parent company Alfa Auto Machinery Co., Ltd, Gamma is established based on the specific needs of customers. The chairman of ALFA, Mr. Shi Fuxing founded Dongguan Gmtek Technology Limited and Suzhou Gamma Automation Tech Co., Ltd in 2006 with the foundation of 2 million US dollars. The main services of Gamma are precision machining and professionally developed and manufactured high speed vertical machining center. Since the establishment, Gamma strives to fulfill the requirements of the customer and continue to provide the customers with the best service no matter if it’s precision, machining speed , the cost performance or the flatness.

High Speed Zipper Strip Hot Lamination Side Sealing Machine | MING JILEE

【Machine Features】 Taiwan-made and stable PLC controller The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan. Zipper Bag Side Sealing Machine is equipped mark sensor for printed material. For getting the best quality of zipper bag product, unwinding station is mount the auto tension control. The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality. Ultrasonic welding is design by motor driven for highest speed production. The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting. 【Company Intro】 Ming Jilee Enterprise Co., Ltd. is manufacturing film blowing machinery with materials of PP and LD/HDPE; PP thin and thick sheet making machine; waste recycling and pelletizing machine, stationery making machinery- can produce business file/data bag/file clip/photo pocket/name card pocket/index/bubble paper envelope; sealing & cutting machinery-side sealing bag/t-shirt bag.

User Feedback from Azin Polymer | K 2022

It was an honor to interview Mr. Arash Alivirdi, a sales manager form Azin Polymer, at K 2022. He has been using PRM-TAIWAN for ten years. Let's listen his experience in using PRM-TAIWAN as a major platform for seeking machinery suppliers.

2022 Intelligent Asia - Smart Mold, 3D Printing, Logistics & IoT | PRM Exhibition Tour

Let's PRM take you to the on-site through our online touring video!! In the video, you will be showed the advance technology of 3D printing, application of IoT in logistics and high quality of smart mold & die. 2022 Intelligent Asia has 9 major manufacturing sectors that includes Automation, Robots, Logistics, Cold Chain, 3D Printing, Molds & Dies, Laser, Fluid Power, and Smart Machinery.

分條切片機

分條切片機

Fully Automatic Coreless Bottom Sealed Bags On Roll Making Machine | CHAO WEI

【Machine Spec & Features】 Bottom Sealed Bags On Roll Making Machine (Coreless) Film width: 600 mm / Thickness: 15 micron E.P.C Control & Rollers Device (E+L, German made) Length: 750 mm x Speed: 135 Pcs/Min Production Line Speed: 100M/Min Servo Driven Shuttle Type Sealing & Perforating Unit Two Sets Triangle Folders For Making Finished Roll With Small Width Machine Maintains High Speed Production By 4 Sets Rewinding Shafts While Producing Small Quantity Of Bags Per Roll 【Company Introduction】 Chao Wei Plastic Machinery is an advanced manufacturer of plastic bag making machine with more than 35 years of experience with ISO 9001 & CE certificates in Taiwan. One of the reasons for the excellence of Chao Wei’s machines is our dedication to research and development.

Precision Mold Making & Injection Molding Solutions

Jia Thai Industrial Co., Ltd. Company Profile

Five Layer Blown Film Line | Multilayer Blown Film Machine | Blown Film Extruder - Kung Hsing

/ Kung Hsing Main Products / K.S. manufacture Agricultural Blown Film Machine, Inflation making machine, Flat Yarn making machine, Plastic strapping band making machine, Plastic Recycling Machine, as well as special design for all extrusion system machineries and whole plant projects. #KUNGHSINGPLASTICMACHINERY #BLOWNFILMLINE #MULTILAYERBLOWNFILM

2024 NPE Orlando Interview | ISI

I had the pleasure of meeting Mr. Joe Whann at NPE Orlando. Joe is not only brilliant but also incredibly friendly! He provided an insightful introduction to the wide range of services offered by ISI and shared how they have become a leading agent in the USA. Don't miss out on learning about their impressive journey and expertise!

Extrusion Blow Moulding Machine |FONG KEE

Extrusion Blow Moulding Machine - High Speed Blow Moulding Machine-hbb-ssg-Fong Kee Specializes in Extrusion Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Extrusion Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Extrusion Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.

Eksim x PRM: Bridging Taiwan and Turkey in the Plastics Industry

Join us at PlastEurasia Istanbul 2024 as we interview Eksim, a prominent agent representing renowned Taiwanese brands like FKI, CLF, and LYM. Discover Eksim’s insights into the Turkish market and their strategies for building long-lasting, mutually beneficial relationships with Taiwanese manufacturers. Don’t miss this exclusive look into how Taiwan’s expertise supports Turkey’s growing demand for advanced plastic and rubber machinery!

Saudi PPPP Through Familiar Eyes: Cosmo’s Perspective on an Evolving Show

Where is Saudi PPPP headed? In this on-site interview, Cosmo shares insights from years of participation, noting subtle shifts—like fewer machines on display. More significantly, Messe Düsseldorf’s quiet partnership hints at deeper changes in the region’s manufacturing and exhibition landscape

Double Lines T-Shirt Bags Making Machine:ST-88-G2 | COSMO

Fully Automatic High Speed Double Lines T-Shirt Bags Making Machine with Hot Slitting & Side Gusseting Device. Model : ST-88-G2 Machine Features: https://www.cosmo886.com.tw/en/products_i_High_Speed_T-Shirt_Bag_Making_Machine_with_hot_Slitting_and_Side_Gusseting_Unit_ST-88-G2.html ➤Contact Us COSMO MACHINERY CO., LTD. Web: https://www.cosmo886.com.tw

Shanghai World of Packaging (swop) 2024

Messe Düsseldorf (Shanghai) Co., Ltd. and Adsale Exhibition Services Ltd. will join hands to present the Shanghai World of Packaging (swop) from 18th to 20th November 2024 at Shanghai New International Expo Centre (SNIEC). As a member of the interpack alliance, in addition to continuing to exhibit the packaging industry chain, swop will discuss industry-leading keywords with packers, brands, OEM/ODM, including lightweight, light assets, youth, intelligence, personalization, new materials, new technologies, sustainability, new design trends and other popular topics, sharing packaging cutting-edge concepts and technologies. From materials, equipment, and products to design and marketing, swop is definitely your 360° solution provider in the packaging industry! Find out more at https://adlnk.cn/A3Qm7K5

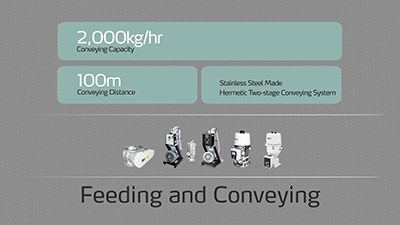

Plastic Dryer, Hopper Loader, Gravimatric Blender | SHINI

Plastic Dryer, Hopper Loader, Gravimatric Blender - Products Overview -Shini Specializes in plastic dryer and hopper dryer. SHINI PLASTICS TECHNOLOGIES, INC. products including hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chillers, sprue picker, side entry robot,gantry robot and more. The Shini Group, Originate from Taipei, Taiwan since 1969. Five manufacturing bases and one corporate technologies center around the world. World class manufacturer of plastics auxiliary equipment. For 41 years, Shini people adhered to the management principle of Focusing on Particular Business, Pursuing to be the World Leader which created new era and achieved many progresses. Shini Group has now become a world-class manufacture of plastic dryer, hopper dryer, hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chiller, sprue picker, side entry robot, gantry robot.

Screws / Barrels for Extrusion and Injection Molding | NAN YUN

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6 Are you still seeking appropriate suppliers under the unstable circumstance of COVID-19? We heard your concerns and heartfelt wishes for attending an online exhibition! Through PRM Theme Pavilion, without traveling abroad, you will have many opportunities to connect with the world. Now, we are excited to announce an upcoming new event PRM Theme Pavilion, which will bring you to the new horizon. In this video, we are gonna present what you will see in this online exhibition. This time, we will focus on showcasing manufacturers who are specializing in the packaging industry. Let's take a look at the PRM What to Say episode 6, where we are evaluating and introducing the next PRM Theme Pavilion which focuses on the Packaging industry. In the video, you will learn more about not only what this event is about, but also the benefit of the event for global visitors, how the event is planned and concentrated on a specific focus with the selected machine manufacturers and machinery lines that a packaging business all need.

線上代看展 | 2022 台中自動化工業展

皮亞恩 x 普拉瑞斯您在現場做直播,讓您在線上也能夠觀看2022 台中自動化工業展! 本次參展的廠商類別多達8種,為大家帶來最新的展況和機台設備 直播時間: 2022/7/16 15:00 (GMT+8) 地點: 台中國際展覽館 展商類別: 工具機 五金工具暨配組件 切削刀具 塑橡膠 產業機械 自控檢測區 中台灣工業協進會 產學合作專區

Twin Head Blown Film Machine for Plastic Bag Manufacturers | POLYSTAR

Introducing POLYSTAR Twin Head Blown Film Machine with the motto of the company: "Extrusion Made Simple". The blown film extruder is specially designed for HDPE and LDPE bag producers. 【HIGHLIGTS OF Twin Head Blown Film Machine】 - Monolayer (1 Layer) - Two Die Heads, Single Screw - Film Width from 150~650mm - Extruder Dia: 45mm, 55mm, 75mm - Material: HDPE, LDPE - Output: 30~140 kg/hr - Works with virgin, recycled materials, Biomaterials, and CaCO3 - Possible end products: T-shirt bags, Bottom sealed flat bags, Shopping bags, Supermarket bags, Garbage bags 【MACHINE PORTFOLIO OF POLYSTAR】 1. BLOWN FILM MACHINES - One Layer Twin Head HDPE LDPE 650mm Machine - Multilayer Blown Film Machines - One Layer HDPE / LDPE 800mm (Mini type) Machine - AB - 2 Layer Co-Extrusion LDPE/LLDPE Machine - One Layer HDPE LDPE LLDPE 1500mm Machine 2. BAG MAKING MACHINES - Bottom Sealing Bag Making Machines - Folded Garbage Bags Machines - Perforated Bag on Roll Machines - Thick Bag Making Machines - Laundry Bags Machines 3. RECYCLING MACHINES - Plastic Recycling Machines - Plastic film recycling Machines - Two stage recycling Machines - Air cooled recycling Machines - Hopper feeding recycling Machines - Shredder integrated recycling Machines 【ABOUT POLYSTAR】 POLYSTAR is a pioneer manufacturer of Plastic Recycling Machines, Blown Film Extruders, and Plastic Bag Making Machines. The company has gained the trust of its customers with 32 years of experience in the industry, today POLYSTAR has been sold over 4,000 machines in 105 countries worldwide.

PET Bottle Recycling System and Process for Food Grade Flakes | BoReTech

BoReTech has been a specialized manufacturer focusing on the customized R&D for PET recycling production since 1989. Moreover, the company also has more than 15 years of manufacturing experience. BoReTech provides a total solution of the plastics recycling system, polyester staple fiber production, and many more. In the video, you will find the on-site machine introduction of : PET Bottle Recycling System Process for Food Grade Flakes Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan

The Most Reliable PP/PE/PET Woven Bag Machinery Maker | HAO YU

Hao Yu Precision Machinery Industry Co., Ltd. is a leading manufacturer of PP/PE/PET woven bag machinery and whole-plant equipment. Since its establishment in 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence of HAO YU machines. Our objective is to enhance our present machinery and develop new models that improve the efficiency, product quality and profitability for our customers.

PP Woven Bag Fully Automatic Liner Inserting-Bag Top Hemming Conversion Line | BOTHEVEN

【MAIN FEATURE】 All in one multi-functional machine - Flexible Usage for various type of PP woven bag Processing on the same machine. Available for PP woven bags: ● With liner Inserting-Cutting-Sewing and bag top hemming process ● With Cutting-Sewing and Bag Top Hemming Process Only (Without Liner Inserting) ● With Liner Inserting-Cutting-Sewing Only (Without Bag Top Hemming process) Cutting-Sewing Process only (Without Liner Inserting & Without Bag Top Hemming) Saving Manpower, Space and Saving Cultivated Training for Skilled Manual Operation to the Maximum. Producing Finished Bags with Conformed & unified quality with stable performance Experiencing Clean Process of Bag Top Hemming, largely Reducing Hang-Touching on the bag top area. Highly synchronized machine for Easy Setup and quick bag size changeover. A Total-Solution Machine for PP woven bags with Final Products Applicable in a Big Variety Market. 【COMPANY INTRO】 Botheven Machinery Industrial Co., Ltd, (Since 1984), has accumulated more than 30 years of technical experience & know-how in the planning design, manufacturing, sales and service of PP/HDPE Woven Bag Making Machines in Taiwan. Our equipment has been sold worldwide with assured quality, stable performance and reliable after-sales services. We can build machinery according to customers' requirement; also provide cost-down solution for customers.

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES OF THE MACHINE: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Automatic Log Roll Cutting Machine|Four-Shaft Log Roll Cutter | Yicheen

Automatic Log Roll Cutting Machine can be applied to cut rolls of various tape materials, such as double-sided tape, electrical tape, masking tape, construction tape, etc.. More product info: ???? https://bit.ly/3q8uLWw / Automatic Log Roll Cutting Machine Features / Cutting running is driven by AC motor with inverter control. Fast and stable to speed up & down. PLC control system Auto change cut size setting in the same shaft. Precise and smooth positioning. Multi-speed cutting rolls to improve operating efficiency and maintain high quality. The blade has different angle changes according to different materials, reducing the number of tool changes. / Advantages of Yicheen / Leading the industry in the research and development of the Die-Cutting Machine". In addition to the continuous improvement of technology, it has also developed a variety of Printing Machines, Laminating Machines, Cutting Machines, Sheet Cutting, Slitting Machines, and other equipment to provide complete plastics Processing equipment solutions. / links of Yicheen / Contact us: https://bit.ly/3q8KLaK Subscribe us: https://bit.ly/3wGjjU3 Product Info: https://bit.ly/3tU2QdK

Plastic Blow Molding Process Explained | PRM What to Say EP 13

In blow molding, hollow plastic components are formed through a producing process categorized into three main methods: injection, extrusion, and injection stretch blow molding. In this episode of PRM What to Say, the plastic blow molding process is explained. Besides, we also mentioned some common benefits of the blow molding production method. For more info and machine manufacturer info, you can refer PRM-TAIWAN Blow Molding Machine category at Blow Molding Machine Category Since blow molding allows freedom for design and engineering, the range of applications that you can manufacture by blow molding is really wide. The automotive industry, Appliance components, Medical supplies and parts, Children’s toys, Packaging, Sporting Goods, and Industrial bulk containers are where we see blow molded products often. The blow molding process is very suitable for automation. Especially using the robot technology for take out units and packaging offers the benefit of faster production. Besides that, you can also reduce labor costs by using automation.

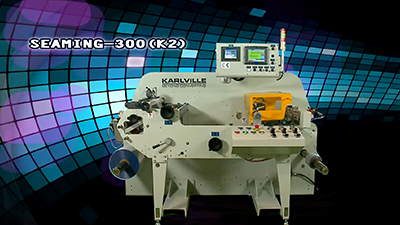

Seaming Machine | WEBCONTROL

Seaming Machine-300(K2)-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

【K show 2022】Plastic Bag Making Machine | Bag On Roll Making Machine - PAL

PAL has decades of experience in Plastic Bag Making Machine manufacturing, and continues to develop, manufacture, and sell to all over the world, and even participates in exhibitions around the world.

傳感器 & 聚合物測驗設備 | Dynisco

PRM-TAIWAN曾在2019的K採訪過Dynisco全球副總裁Bill Desrosiers,歷經了三年全球環境大轉變後,我們很榮幸再與Bill見面。 Bill向我們講述這三年來產業間的轉變,以及K三大主題的應用。另外提及Dynisco在今年參展的首要任務,是要和全球的夥伴們分享最新的技術發展以及如何應用於循環經濟

UHS Turret Slitter Rewinder - UHS-TR | WEBCONTROL

UHS Turret slitter rewinder The UHS-TR model is a proven fully automatic slitter rewinder, offered with many options to fulfill even the most demanding applications: - Cutting-edge slitting systems - Reliable auto cut and transfer - Advanced tension control - Combined with progressive differential winding technology - Precision and capacity at an affordable cost. - UHS-TR a must addition to any plant requiring quality Automatic knife positioning down to 25 mm slit width, double turret unwind, automated finished roll unloading systems are some of the available options to increase productivity, quality and decreasing operator influenced down time. Materials to be processed: Plastic film, paper and laminates Thickness range: -Rigid films: 10 – 200 micron -Soft films: 12 – 300 micron Machine Specification - SLIT UHS TURRET: -Web width:1300 / 1600 mm max -Unwind roll diameter: 1000 mm -Unwind roll weight: 1500 kg -Unwind roll cores: 3” and 6” I.D. -Finished roll diameter: 610 mm max -Finished roll cores: 3” and 6” I.D. -Slit width: 50 mm and up -Machine speed max: 600 m/min (depending on material type/quality) -Winding tension: 0.5 pli to 2.5 pli (11 - 45 kg) standard

2023 CHINAPLAS 國際橡塑展 4/17-4/20

CHINAPLAS 2023 國際橡塑展 聚集海內外各大廠商的塑橡膠產業國際盛會!跟著PRM,帶你行銷全世界! 日期:2023年4月17-20日 開放時間:09:30-17:00 地點:中國.深圳國際會展中心 (廣東省深圳市寶安區福海街道展城路1號)

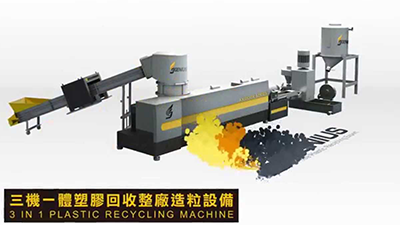

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS Specializes in waste plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in waste plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our waste plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. Product Feature: -Drive-train: High torque gearbox made with precision grinding. Low noise, steady and smooth operation. -Low power consumption, high output. Dedicated screw and barrel design: According to the characteristics of recycle materials, dedicated screw is designed to completely impurities such as water and bad air; the screw also has a variety of advantages, for examples, good mixing, good dispersion, high output, and others. Die head pelletizing eliminates the labor cost on batter brace. No water tank. Consumes less space. Extruder is equipped with pressure sensors. When there is excessive pressure, warning light or buzzer send notification for replacing filter screen. No need to shut down the machine when replacing the filter screen. Single extruder suitable for cleaner material pellets such as injection leftovers, edge trim.

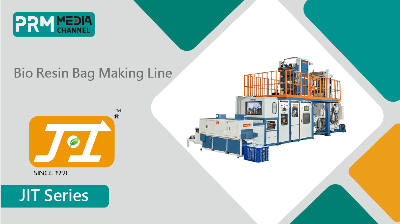

JIT-SS |JIT T-Shirt Bag Making Line |JANDI'S

【Machine Features】 Mono-layer, 2+0 printing Power Required Reduced Processing Waste Reduced Production Mistake Reduced CO2 Emission Reduced Total Lead Time Reduced Labor Cost Reduced Recover Die-cut Material Storage Space Reduced 【Company Intro】 JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

The Best Choice of Bag Making Machines | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Product Lines】 T-shirt Bag On Roll Making Machine Bag On Roll Making Machine T-shirt Bag Making Machine Garbage Bag & Industrial Bag Making Machine T-shirt & Bottom Sealing Bag Making Machine Side Sealing Bag Making Machine Air Cushion Bag Making Machine Stretch Rewinder Glove Making Machine 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

U Liner Bag Making Machine SHCG-75U | SING SIANG

SING SIANG MACHINERY CO., LTD