Find Your Plastic & Rubber Supplier | PRM-TAIWAN

Welcome to PRM-TAIWAN Plastic & Rubber B2B Website introduction video. In this video you will watch how to find Taiwanese Plastic and Rubber Machinery suppliers through PRM-Taiwan. It's so simple! Just go to www.prm-taiwan.com select the machinery or materials, and send your inquiry. Leave the rest part to us.

Food Processing Machine Solutions | HUNDRED MACHINERY

Since 1996, Hundred Machinery Co., Ltd. has been the professional automatic encrusting machine manufacturer in Taiwan. PRM Media Channel had an interview at the recent TAIPEI PACK and had a chance to introduces the companies automatic food processing machinery lines. Let us know your opinion and the inquiry in the comment section. Stay tuned for the forthcoming interview videos and remember to subscribe to our social media channels for similar videos!~ MAIN PRODUCTS/SERVICES OF HUNDRED MACHINERY:

Blown Film Extrusion Line | FONG KEE

Blown Film Line - Three Layer Co-Extrusion Blown Film Line Located in Taiwan, FKI is the manufacturer of Three Layer T-Die Co-Extrusion Cast Film Machine. The demand of the Mono Layer/Multi layer T-Die Cast Film Extrusion Line has became more and more, which widely involved in many applications of packaging field, such as: 1. Decoration film 2. Gift wrapping film 3. Flower wrapping film 4. Stationery product packaging film 5. Lining film for dry/wet lamination 6. Sanitary product packaging film 7. Flexible packaging film 8. High barrier food packaging film With its outstanding optical and physical properties, either the mono layer or multilayer cast film being widely used in many applications, due to the well developed materials grades and additives, plus the well designed processing equipment with high precision control system as a full package to set the positiveness.

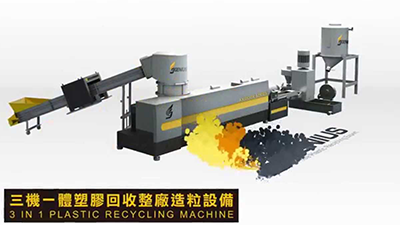

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS Specializes in waste plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in waste plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our waste plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. Product Feature: -Drive-train: High torque gearbox made with precision grinding. Low noise, steady and smooth operation. -Low power consumption, high output. Dedicated screw and barrel design: According to the characteristics of recycle materials, dedicated screw is designed to completely impurities such as water and bad air; the screw also has a variety of advantages, for examples, good mixing, good dispersion, high output, and others. Die head pelletizing eliminates the labor cost on batter brace. No water tank. Consumes less space. Extruder is equipped with pressure sensors. When there is excessive pressure, warning light or buzzer send notification for replacing filter screen. No need to shut down the machine when replacing the filter screen. Single extruder suitable for cleaner material pellets such as injection leftovers, edge trim.

PIRANHA-45, Mini recycling machine | Lung Meng

PIRANHA-45, Mini recycling machine | Lung Meng

rPET Bottle for Household Packaging Solution | ChumPower

Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries. 【Product Appliance】 Beverages Water Edible Oil Daily-used Cosmetics 【Product Range】 One Stage Injection Blowing Machine Injection and Bottle Molding Manufacturing Stretch Blow Molding Machinery Sales / Turnkey Solution TS Series Models for Lower Production Output (Suggest to new market players) Linear PET Blow Molding Machine (Suggest to buyers who is looking for higher output) 【SS10-rPET Single-stage PET Bottle Blowing Machine】 Hybrid hydraulic system with an optimized clamping mechanism to ensure Energy Efficiency Barrier screw with venting capability can effectively lower the energy required for drying Adopt 4 station design Non-contact feature Reach the trending topics of ESG, Carbon Neutrality, and Net-Zero Emission

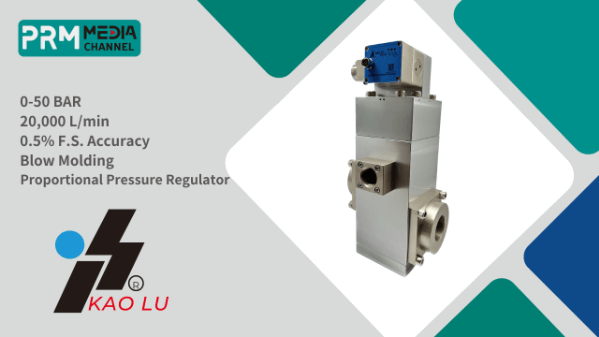

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | 高鹿興業

產品敘述 QKL-B1T/B3:在 0–8 bar 可調範圍內可用。 QKL-B1S / B3H:可調範圍為 0–30 bar。可定制壓力範圍,流量高達 3500 L/min QKL-B4H:最高可達 70 bar 除了這些產品類型外,也可以依據您的需求訂製,例如:當您想要填充大型密閉容器時提高流速,或您需要隨時與外部壓力傳感器配對使用。 想了解產品相關操作和應用,歡迎參閱我們的 Youtube頻道。 壓力比例閥 壓力比例閥又稱電空比例閥。幾乎所有氣動和液壓系統中都有壓力控制閥,它們有助於實現多種功能,並讓系統壓力保持在所需數值設定壓力。不同類型的壓力控制閥包括:溢流閥、減壓閥、順序閥、平衡閥、安全閥和卸載閥。除了打開減壓閥外,大多數的閥門通常都是關閉的,以產生所需的壓力控制。其中一個例外是外部先導卸荷閥,它依賴於外部信號進行驅動,該信號通常來自比例壓力調節器或數位壓力比例閥。在某些應用中,例如:呼吸機和麻醉機,流量必須始終保持一致,這就是控制閥如此重要的原因。 數位壓力比例閥也稱為電動氣動調節器,它是一種可以數位控制的氣動壓力調節器。高鹿提供 0-10VDC、4-20mA、RS485 modbus 命令信號方式。以我們的產品 QKL-B3H 為例,假設可調壓力範圍為 0-30 bar(或 0-435 psi)、輸入信號為 2VDC、輸出壓力為 6 bar(87 psi)、輸入 8VDC 信號、輸出壓力為 24 bar(348 psi)。 壓力比例閥種類 壓力比例閥又稱電空轉換器、電空比例閥或電氣比例閥。因應市場需求,高鹿的壓力比例閥範圍可從真空到高壓(-1 ~70 bar,一般市面上看到的同性質產品約 30bar),除了具有高分辨率(0.5~0.6 bar 可移動量),更有快速響應時間、交期快速及品質穩定等多項優勢。 高鹿製造三種類型的高品質壓力比例閥,壓力範圍可分為真空 -1~0 bar、低壓 0~2 bar /0~4 bar / 0~8 bar、中壓 0~18 bar / 0~30 bar、高壓 0~70 bar。在高壓的控制上,精度可達 0.5~0.6 bar 的高分辨率。適用於細胞抽取、玻璃機械、輪胎機械、塗裝設備、吹塑機械、激光雷射機械等醫療或工業應用。 我們的壓力比例閥採用閉迴路設計,由兩個電磁閥、壓力傳感器及電子迴路控制組成。根據接收到的類比訊號輸入,由一端電磁閥控制進氣量,另一端電磁閥控制排氣量,透過壓力傳感器測量,並回饋電子迴路控制,以達到精確的壓力比例控制。該比例閥適合隨時需要精準調控壓力變化和監控壓力值的產業。比例閥輸入信號提供 0-10VDC(電壓)與 4-20mA(電流)及 RS485 ModBus 通訊選擇;監控輸出則有 1-5V、0-10V 及 4-20mA 的選擇。 若您需要在遠端壓差的環境條件下使用本產品,我們所設計的另一個功能可搭配外部壓力傳感器,除了會自行調控達到恆壓外,還能回饋參數到機台上做監控,排除壓力值不準或壓差造成的震盪問題。如需高流量,本公司也提供氣引導流量放大氣,給需要大流量的應用產業。 本產品皆符合 CE 認證、SGS、RoHS、ISO13485 認證。 應用案例 壓力比例閥適用於醫療或工業場景,例如細胞提取,玻璃機械,輪胎機械,塗層設備,吹塑機械,激光機械...等。 噴塗設備 吹氣 洩漏測試 填充設備 人工心臟 雷射切割 壓力比例閥 QA 時間 壓力比例閥可以運用在哪些產業? 雷射切割、塑/橡膠吹塑成型機、運用張力控制機台、輪胎成型機等。 壓力比例閥耐髒嗎? 怕髒(需使用過濾後乾淨的空氣,請安裝空氣過濾器。過濾精度應選 5µm 以下)。 壓力比例閥擺放上有無限制? 安裝方向無限制(但附著水滴、油及焊渣的場所環境,請採取適當的保護對策)。 【如需更多有關壓力比例閥的資訊,請參考產品應用案例】

PP Flat Yarn Extrusion Line & Raffia Tape Stretching Line Plant|HAO YU

The extrusion line has maximum PP melting output. Capacity is 160 ~ 520 kg/h and the unit is equipped with a screen filter changer and rotary blade slitting system. The machine has less down time and prevents production loss. The pressure rollers of the take-off unit are pneumatically controlled, and have synchronized control electronic system. Available to meet special requirements. 【Company Introduction】 Hao Yu Precision Machinery Industry Co., Ltd. is a leading manufacturing of PP and PE woven bag machinery and whole-plant equipment. Since its establishment 1980, HAO YU has been dedicated to the research and development of high performance machinery.

線上代看展 | 2022 台中自動化工業展

皮亞恩 x 普拉瑞斯您在現場做直播,讓您在線上也能夠觀看2022 台中自動化工業展! 本次參展的廠商類別多達8種,為大家帶來最新的展況和機台設備 直播時間: 2022/7/16 15:00 (GMT+8) 地點: 台中國際展覽館 展商類別: 工具機 五金工具暨配組件 切削刀具 塑橡膠 產業機械 自控檢測區 中台灣工業協進會 產學合作專區

Bio Resin Bag Making Line - JIT Series | JANDI’S

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

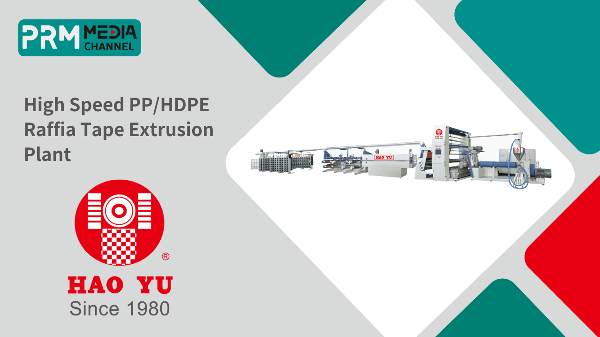

Flat Yarn Extrusion Line & Raffia Tape Stretching Line | HAO YU

HAO YU Raffia Tape Stretching Line is designed for producing PP/HDPE raffia tape and flat yarn. 【Equipment Features】 - Capacity: 160 ~ 520 kg/h - Designed for making 500-1500 denier - Working speed 100-270 meter/minute - A screen filter changer - Rotary blade slitting system - Synchronized control electronic system - Low energy consumption - Less downtime - Reduce production loss 【Additional Features】 - European-made gearbox - T-die - Melt pump - Tape winder - Designed for making 2000-6000 denier upon special request 【Finished Products】 - Woven bag - Geotextile - Artificial grass - Carpet backing production 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

Precision Mold Making & Injection Molding Solutions

Jia Thai Industrial Co., Ltd. Company Profile

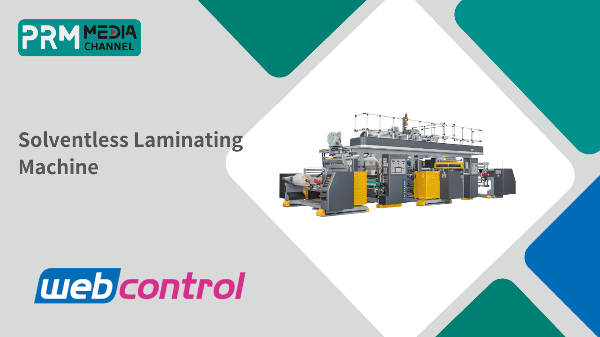

Solventless Laminating Machine (LM SF1300T) | WEBCONTROL

Webcontrol develops innovative solventless laminators with driven coating system and automatic turret unwind & rewind for high efficiency, consistent tension & minimum waste during roll changes.

High Speed PP/HDPE Raffia Tape Extrusion Plant | Raffia Tape Extrusion Line | HAO YU

【New generation high speed PP/HDPE raffia tape extrusion plant - GV series (Green Veloz)】 / Raffia Tape Extrusion Line/Plant Features - (HY7/SP-80GV) / ⚡️Suitable for making 100% recycle PP/HDPE materials ⚡️Finish products complies with the requirement of GRS(Global Recycled Standard). ⚡️Meet the requirements of companies interested in selling their products to ESG approved companies. ⚡️Rapid color changing.

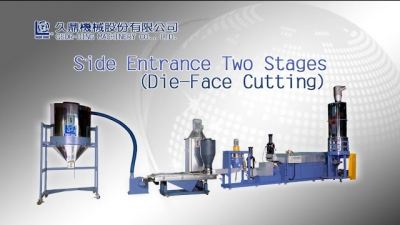

Side Entrance Two Stages System | GEOR DING

Side Entrance Two Stages System - Side Entrance Two Stages Die-Face Cutting Recycling & Pelletizing Machine GEOR-DING MACHINERY CO., LTD.. - Manufacturer of Side Entrance Two Stages System and more. We specialize in manufacturing of Side Entrance Two Stages System. The main businesses include: Side Entrance Two Stages System and the planning of the entire plant’s equipment. While the demand for output and quality in Side Entrance Two Stages System worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Side Entrance Two Stages System products and services to higher standards.

Eksim x PRM: Bridging Taiwan and Turkey in the Plastics Industry

Join us at PlastEurasia Istanbul 2024 as we interview Eksim, a prominent agent representing renowned Taiwanese brands like FKI, CLF, and LYM. Discover Eksim’s insights into the Turkish market and their strategies for building long-lasting, mutually beneficial relationships with Taiwanese manufacturers. Don’t miss this exclusive look into how Taiwan’s expertise supports Turkey’s growing demand for advanced plastic and rubber machinery!

Triangle Folding Machine, 1 Color Rotogravure Printing | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000 from MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

Thomas Dohse -探索包裝機械的未來 | 上海 swop 專訪

在上海 swop 的獨家專訪中,我們與 Interpack 的關鍵人物 Thomas Dohse 深入探討包裝機械的未來以及塑造行業的新興趨勢。 發掘 swop 展覽中的精彩亮點,包括創新技術和對最新進展的獨特見解。 Thomas 也分享了他對全球化復甦的看法,全球化已透過分散且分散的交易以新的形式出現,為全球企業創造新的機會。 最後,Thomas 帶我們窺探了 2026 年的國際包裝展,揭開了其中心主題以及我們可以在這場全球盛會中期待的內容。請不要錯過這場結合前沿趨勢與未來包裝願景的精闢討論!

Plastic Blow Molding Process Explained | PRM What to Say EP 13

In blow molding, hollow plastic components are formed through a producing process categorized into three main methods: injection, extrusion, and injection stretch blow molding. In this episode of PRM What to Say, the plastic blow molding process is explained. Besides, we also mentioned some common benefits of the blow molding production method. For more info and machine manufacturer info, you can refer PRM-TAIWAN Blow Molding Machine category at Blow Molding Machine Category Since blow molding allows freedom for design and engineering, the range of applications that you can manufacture by blow molding is really wide. The automotive industry, Appliance components, Medical supplies and parts, Children’s toys, Packaging, Sporting Goods, and Industrial bulk containers are where we see blow molded products often. The blow molding process is very suitable for automation. Especially using the robot technology for take out units and packaging offers the benefit of faster production. Besides that, you can also reduce labor costs by using automation.

High Speed Side Sealing Machine with Wicketer | LIAN YOU

High Speed Side Sealing Machine with Wicketer

Current Situation in Indian Extrusion Market | CCM India Interview

At the end of 2020, we had an online interview with Mr. Prashant Tanna from CCM India(Chichang Machinery India). At the interview, we have discussed various topics related to the plastics and rubber industry. Mr. Tanna sincerely replied to our questions and shared a deep insight especially about the plastics extrusion machinery market in India. We are grateful for the insight that we gathered from Mr. Tanna about the current situation of the Indian market, travel restrictions, benefits of having an agent in the local market, and so on. Let's watch the interview video together and leave your comment at the comment section!

2023 Plast Eurasia Interview | WEI MENG

It's our great honor to interview WEI MENG and their Turkish agent in the 2023 PlastEurasia. Watch our video for more information!

2024 CHINAPLAS Interview | ChumPower

We are here with Mr. Bush and Mr. Michael from HCI Converting Equipment at the CHINAPLAS. Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries.