Proportional Pressure Regulator Valve | QKL-B2T+External Pressure Sensor | KAOLU

00:00 QKL-B2T Proportional Pressure Regulator Valve + External Feedback Pressure Sensor Product Introduction 00:21 QKL-B2T+External Feedback Pressure Sensor Description 00:29 Product Function: Boost Flow 00:40 Product Feature: Remotely controls cylinder pressure What is a Proportional Pressure Regulator Valve? In pneumatic world, a proportional pressure control valve is used to control downstream air pressure with an electronic signal. The input electronic signal is proportional to the span of the output pressure. For example, 0-10VDc of command signal corresponds to the output pressure span of 0 - 10 bar, with linear proportion relationship. Type of Proportional Pressure Regulator Valve? Kao Lu offers three types of electronic proportional pressure regulator: pressure ranges from vacuum -1~0bar, low pressure 0~2bar, 0~4bar, 0~8bar, medium pressure 0~16bar, 0~30bar, up to high pressure 0~70bar. In the high pressure control, the resolution can reach 0.5~0.6 bar. Proportional Pressure Regulator Valve Working Principle? Proportional Pressure Control Valve adopts a closed loop design and consists of two solenoid valves, an internal pressure sensor and an electronic control; according to an analog signal input, one solenoid valve is used to control the air intake and the other is used to control the pressure. Both valves work together to achieve a precise proportional pressure control. The proportional pressure regulator adopts two types of input signals: 0-10VDC or 4-20mA, and three types of monitor output signals: 1-5V, 0-10V or 4-20mA.

Innovative Technology in Plastic Recycling | BoReTech-

BoReTech is a leading company in the plastic recycling industry. With more than 30 years experience in the industry, BoRetech is introducing its brand new designed ES process.

Air Bubble Film Extrusion Line - CHI CHANG

Air Bubble Film Extrusion Line - 2.5M Wide 3-layer Air Bubble Sheet Extrusion Line The 2.5M Wide, 3-layer Air Bubble Sheet Extrusion Line produced by Chi Chang Machinery Enterprise Co.,LTD has excellent quality and an outstanding reputation. The Air Bubble Film Extrusion Line includes Take-off unit & winder, In-line lamination, T-Die & laminating unit and EPS/EPE reclaim system.

Rubber & Silicon lnjection Molding Machines | LONG CHANG

Long Chang is manufacturing the series of Rubber & Silicon injection Molding Machines, and Heated Compression Molding Machines etc. 【Machine Series】 Silicone Injection Molding Machine Rubber Injection Molding Machine Horizontal Automatic Rubber & Silicone Injection Molding Machine Single Body / Twin Body Vacuum Oil Hydraulic Compression Molding Machine Vacuum Rubber Oil Seal Hydraulic Compression Molding Machine Single Body / Twin Body Die-Moving & Ejection Compression Molding Machine Four Columns Type Oil Hydraulic Press EVA Foam Tire / Single Body Double Color Of Automatic Oil Hydraulic Compression Molding Machine 【Company Introduction】 Long Chang Mechanical lndustrial Co., Ltd. was established in 1971, under the leadership of president Huang Chin-Huo with the idea of "always be loyal to the obligation, give more than enough thought to operate the business" and demands "making the perfection more perfect" to be the target.

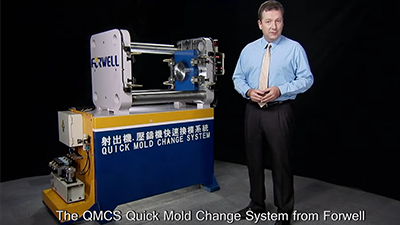

Quick Mold Change | FORWELL

Quick Mold Change - Quick Mold Change System-forwell-qmcs-en-Forwell Features • Decreased mold change time • Fully customizable to fit a wide range of machines • Safer operations • Reduced labor costs • Easy changeover for small batch runs System Introduction : Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds. Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations.

Taiwan Injection Molding Machine | CLF

Taiwan Injection Molding Machine - Chuan Lih Fa Products: plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle. Contact Information: https://www.clf.com.tw/en/contact.html

Flexographic Printing Machine | LEEWIN

【Product Lines】 In-line Flexo Printing Machine FSP Off-line Flexo Printing Machine Chamber Dr. Blade Flexographic Printing Machine LL Off-line Flexo Printing Machine Heavy Duty Flexo Printing Machine Logo Flexo Printing Machine Flexographic Printing Machine for Biodegradable Plastic Bag Flexo Printing Machine Opional Equipment 【Company Intro】 LEEWIN brand Flexographic Printing Machines are suitable for reel-to-reel printings of fiber glass cloth, PP/PE woven bags, cellophane, aluminum foil, roller paper, packing paper, tubular films, and PP / HDPE / LDPE / LLDPE polyester bags.

2024 CHINAPLAS Interview | ARBURG

I'm honor to meet Dr. Christoph Schumacher, the vice president Global Marketing from Arburg. Let's hear about what's his thoughts on Chinaplas! And their new type machine launched in China.

Proportional Valves for Plastic & Rubber Industry | KAO LU

KAO LU ENTERPRISES CO. is an professional Taiwanese manufacturer. With experience for over 40 years, it’s one of the leaders of the proportional pressure and flow control valves. With high-quality manufacturing techniques, their distributors spread all around the world. 【Video Outline】 Company Introduction Product Application & Competitiveness Product Introduction Main Customers Application on Medical and Biotech Equipment Application on Plastic and Rubber Equipment Advantages of the Era of Industry 4.0 Contact Information

UHS Turret Slitter Rewinder - UHS-TR | WEBCONTROL

UHS Turret slitter rewinder The UHS-TR model is a proven fully automatic slitter rewinder, offered with many options to fulfill even the most demanding applications: - Cutting-edge slitting systems - Reliable auto cut and transfer - Advanced tension control - Combined with progressive differential winding technology - Precision and capacity at an affordable cost. - UHS-TR a must addition to any plant requiring quality Automatic knife positioning down to 25 mm slit width, double turret unwind, automated finished roll unloading systems are some of the available options to increase productivity, quality and decreasing operator influenced down time. Materials to be processed: Plastic film, paper and laminates Thickness range: -Rigid films: 10 – 200 micron -Soft films: 12 – 300 micron Machine Specification - SLIT UHS TURRET: -Web width:1300 / 1600 mm max -Unwind roll diameter: 1000 mm -Unwind roll weight: 1500 kg -Unwind roll cores: 3” and 6” I.D. -Finished roll diameter: 610 mm max -Finished roll cores: 3” and 6” I.D. -Slit width: 50 mm and up -Machine speed max: 600 m/min (depending on material type/quality) -Winding tension: 0.5 pli to 2.5 pli (11 - 45 kg) standard

Injection Molding Machine CLF-3000TP | CLF

Company Name:CHUAN LIH FA MACHINERY WORKS CO., LTD. CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.

What is Biodegradable Plastic & Bio-based Plastic | PRM What to Say EP9

What are the biodegradable plastics? Are biodegradable plastics recyclable? Are biodegrdable plastics environmentally friendly? What are the types of biodegradable plastics? Where to use biodegradable plastics? We heard your questions and made a research for you, looked for the answers of common questions about biodegradable plastics. We also evaluated difference and similarities of bio plastics and biodegradable plastics. Let's take a look at the video and find out more about these two types of materials!

2024 Expo Plasticos Guadalajara | HAO YU PRECISION MACHINERY INDUSTRY CO., LTD.

Join us as we interview Hao Yu Precision Machinery Industry Co., Ltd. at ExpoPlasticos 2024! We shine a spotlight on Hao Yu’s expertise in manufacturing PP/HDPE woven bag-making machines. With 26 years of local experience in Mexico, Hao Yu’s unique advantage lies in its direct communication with customers, ensuring tailored solutions to meet their needs. Their commitment to sustainability, combined with a strong willingness to engage directly with local buyers, enables them to deliver highly customized solutions that meet diverse needs.

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

Air Cooling LD/HDPE Recycling Machine, MGB-RP-120 - MING JILEE

Air Cooling LD/HDPE Recycling machine is designs for re-pelletizing PE plastic waste material / t shirt bag die cut wasteThe material can be PE blown film waste, T shirt bag handle die cut waste, etc... Air Cooling Type Plastic Recycling Machine is equipped the power save, the SCR power regulator control. The real power consumption is around 15~20 kg. 1. Machine Specification: (1) Machine dimension a. Main machine : 2,770 (L) × 2,530 (W) × 2,060 (H) mm b. control box : 920 (L) × 420 (W) × 1,660 (H) mm (2) Machine weight : 2,430 kg (3) Power preparation : 45 kg (4) Power consumption : 20 kw 2. Machine Performance: (1) Applicable resin : LDPE / LLDPE / HDPE Waste Film (2) Output a. LD/LLD PE : 50 - 60 kg/hr b. HD/ PE : 40 - 50 kg/hr Air Cooling LD/HDPE Recycling Machine Features: (1) SCR power regular for saving power (2) Rotating die cutting head to get good quality of cutting shape (3) Less space required (4) Extra Cooling fan to cool down the PE material. Air Cooling Type Plastic Recycling Machine Further information: https://www.mingjilee.com/en/product/...

線上代看展 | 2022 台中自動化工業展

皮亞恩 x 普拉瑞斯您在現場做直播,讓您在線上也能夠觀看2022 台中自動化工業展! 本次參展的廠商類別多達8種,為大家帶來最新的展況和機台設備 直播時間: 2022/7/16 15:00 (GMT+8) 地點: 台中國際展覽館 展商類別: 工具機 五金工具暨配組件 切削刀具 塑橡膠 產業機械 自控檢測區 中台灣工業協進會 產學合作專區

Cutter Compactor Plastic Recycling Machine - KRIEGER Series | GENIUS

Machinery in the Video: GENIUS KRIEGER Series - KR-125 Cutter Compactor Recycling Machine [VIDEO HIGHLIGHTS] 0:00 Plastic Recycling Machine - KR-125 0:28 Belt Conveyor 0:41 Cutter Compactor 1:00 Main Extruder 1:11 User-Friendly Control Panel 1:26 Dual-Piston Filter 1:36 Die-Face Cutting Pelletizing [KEY FEATURES ] Applicable Materials: PET, PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS, etc. Especially for plastic films, foam, woven and non-woven fabric, raffia, washed & squeezed films, flakes, edge-trimmed, and cutting-edge materials. High torque precision gearbox. Low noise and steady operation. Die-face pelletizing is expected to reduce manpower costs. The screw is specially designed for recycled materials based on their characteristics. The unique design ensures full degassing in operation. SAVE cost, energy, and time. The single extruder is suitable for clean materials such as injection leftovers and production waste. [COST SAVING] Saves energy cost up to 20% Reduces labor cost as only 1~2 operators are needed to operate the whole plant. [SUPERIOR FEATURES] /Compacting & feeding/ The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processing. Increase the highest throughputs for more productivity. /Multiple Cooling/ Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. /Flexible Customization/ GENIUS recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs, presenting a smart and reliable plant.

Two Platen Injection Molding Machine 600TPIIR | CLF

Two Platen Injection Molding Machine 600TPIIR 3D animation from CLF. CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance. 【HIGHLIGHTS OF THE MACHINE】 Clamping Force 1800~4000 TONS Unique two-platen design for clamping mechanism exhibits exceptionally high-speed clamping feature. Clamping force, mold opening stroke, and distance between tie bars are easy to customize. Quick and accurate mold adjustment makes the machine suitable for small lot flexible production. Uniform force distribution on mold ensures the high accuracy of the product. Uniform tension force on tie bars for the dramatic increase of service life. Simplified construction with no wearing problem on toggle clamp. Rigid machine structure, minimum deformation, and consistent product accuracy.

吹膜及回收機械 – 世林機械 | CHINAPLAS 2021

PRM Media Channel再次與CHINAPLAS官媒CPRJ合作,為大家分享塑橡膠產業的見解。 本視頻中,我們邀請世林機械的行銷總監David Lo,來分享吹膜擠出機和塑料回收機的概況。 世林機械在亞洲的回收機器方面,擁有30多年的經驗。除回收機械外,該公司還以吹膜機而享譽全球,並為循環經濟做出了貢獻。 由PRM主管Alice為您帶來的專訪,分析世林的優勢。 以下為大家列出探討的議題: 1. 世林回收機和吹膜機的優勢 2. 世林在循環經濟的貢獻 3. 機台的簡約設計和操作 4. 2021年的願景和發展

High Speed Co-Extrusion Coating and Laminating Machine WCL-H-1300| WORLDLY

High Speed Co-Extrusion Coating and Laminating Machine WCL-H-1300 (300 m/min) WORLDLY In this fast-changing packaging market the multi-layer laminates demand has increased. The Co-extrusion machine allows to use two kinds of resin or more by two or more extrusion units to create multi-function extrusion layers. The variety of resin after melted and go through the feed block then join into the T-die. The side screw has corrosion resistance treatment. It’s fine to work with acid copolymer resin, such as EVA, EAA, EMAA, and Surlyn, etc. The barrel heated by a ceramic heater to ensure more energy-saving and short start up time. Worldly also developed the exclusive extrusion output control system with Germany leading dosing system company. So it provides the very accurate and stable output and coating gauge control during the production. It can save more material especially for the long run jobs. The high-speed H series version of the rewinding splicer adopted with a tracking roller device. It provides two kinds of gap & contact winding mode and gives a uniform and perfectly straight finished winding during high speed running. Also the taper tension can properly control the winding from the beginning roll. So it can reduce the wastage and avoid the wrinkle generate at the inner roll. Worldly utilizes only high quality imported T-dies and maintains a ±3% thickness variation. The inner deckle system is customized in-house to reduce trim and provides uniform high-speed production.

PRM 2021 Market Report through Data Analysis | PRM What to Say EP4

We already left the first half of 2021 behind, it still has been a tough period for many industries including plastics and rubber industry as well. Here, we bring a comprehensive market report through analyzing the data from PRM-TAIWAN B2B platform including global buyer inquiry data by categories. In the fourth episode of the PRM What to Say program Resul, the reporter of PRM Media Channel, invited two of our colleagues from PRM to share their observations of the global market. Daniel is responsible for PRM-TAIWAN B2B Platform which is a marketplace for plastics and rubber machinery, auxiliary and materials. Regarding the platform, Billy is responsible for matchmaking global buyers and Taiwanese suppliers. Through the data we have gathered from PRM-TAIWAN B2B Platform, Daniel and Billy are replying to many different questions that any player of the industry are asking currently. Such as how the situation of the market is, what sub industries are affected negatively and/or positively during the pandemic, what category of the machineries are demanding most for the purpose of what type of applications, and so on. VIDEO OUTLINE 0:00 Highlights in Episode 4 & Video Intro 0:23 Duty of PRM in Plastics and Rubber Industry 1:30 How PRM Market Data is reliable? 2:53 Buyer behavior on PRM-TAIWAN B2B Platform 4:18 Market Insight through PRM Inquiry Data 6:03 Market Demands in the First Half of 2021 7:54 Market Reflection on PRM During the Outbreak 9:50 Video closing Know us more on PRM YouTube:https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/ #PRMMediaChannel #PRMWhatToSay #Inquiry #Data #MarketReport #PRMTAIWAN #Plastics #Rubber #Industry #GlobalMarket #Machinery #B2Bplatform

Precision Mold Making & Injection Molding Solutions

Jia Thai Industrial Co., Ltd. Company Profile

CHINAPLAS 帶看展 1-6館 | PRM-TAIWAN

哈囉!普迷們! 睽違已久的 CHINAPLAS ,各家廠商都拿出了哪些壓箱寶呢?這次就由長期駐點在中國的普拉夥伴——Joey 來帶大家深入展館看看今年的展覽現場的盛況! 歡迎想瞭解塑橡膠產業第一手行銷、貿易的消息的廠商,來找PRM喝咖啡、聊行銷!