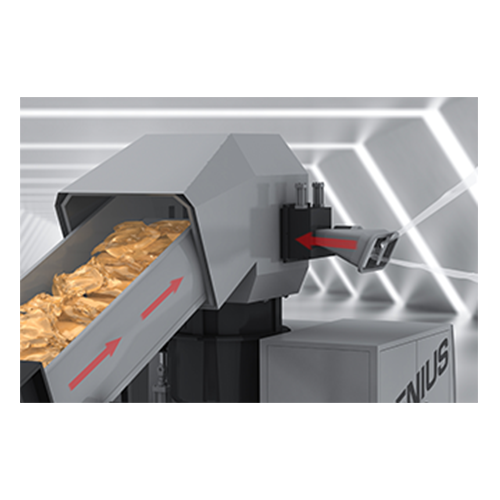

壓縮與入料

高速旋轉的粉碎桶能產生摩擦熱,不只能增加蓬鬆物料的密度也能脫除原料中的水分,藉此提升機器的產能。

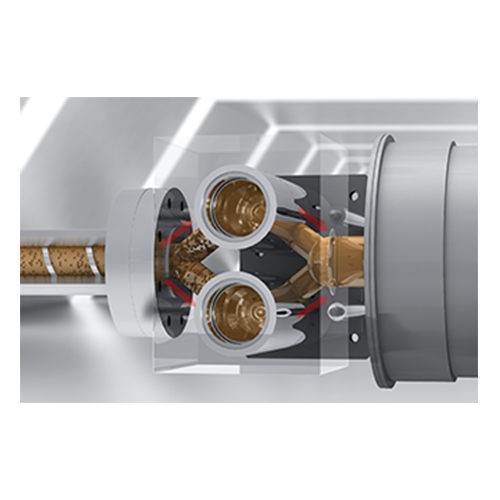

多段冷卻設計

三重冷卻設計–風冷系統、桶身水冷系統和噴水系統。使用者可以設定每段溫度冷卻系統的啟動溫度,以穩定的方式控制粉碎桶的溫度。

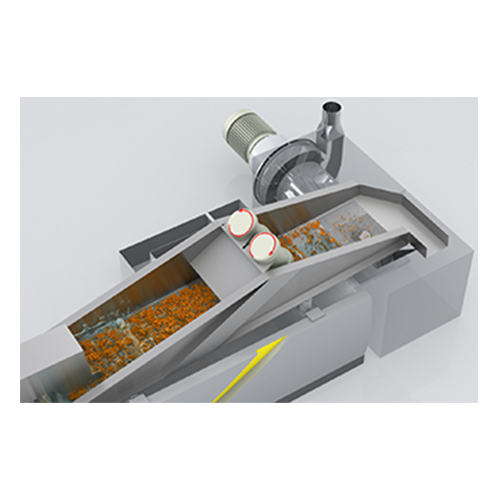

更靈活的設計

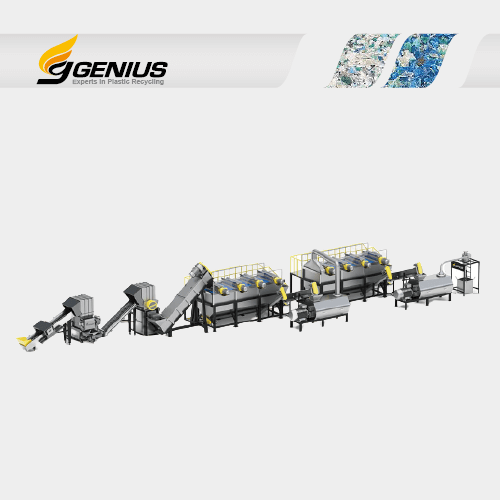

長毅機械提供靈活的選擇,從客製化的回收、分類、入料,脫氣、過濾、造粒到儲存和包裝系統。根據客戶需求提出智能可靠的設備。

型號

KR-65

KR-85

KR-100

KR-125

KR-135

KR-150

KR-175

螺桿直徑

Ø65 mm

Ø85 mm

Ø100 mm

Ø125 mm

Ø135 mm

Ø150 mm

Ø175 mm

押出機馬達

40HP

(30KW)

75HP

(56KW)

125HP

(94KW)

175HP

(131KW)

200HP

(150KW)

250HP

(188KW)

350HP

(262KW)

粉碎桶馬達

30HP

(23KW)

60HP

(45KW)

75HP

(56KW)

100HP

(75KW)

125HP

(94KW)

150HP

(112KW)

175HP

(131KW)

產量 (kg / hr)

80 ~ 100 ↑

200 ~ 300 ↑

300 ~ 400 ↑

450 ~ 600 ↑

650 ~ 850 ↑

700 ~ 800 ↑

900 ~ 1100 ↑

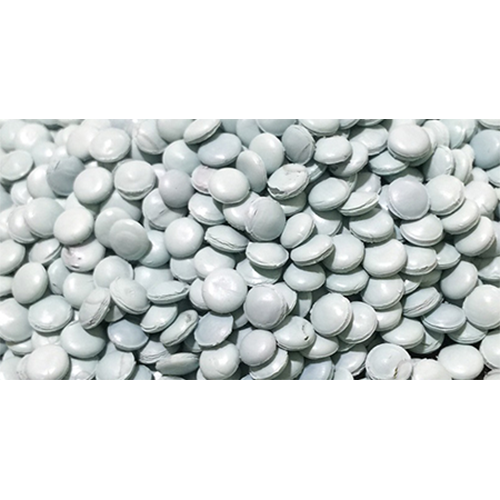

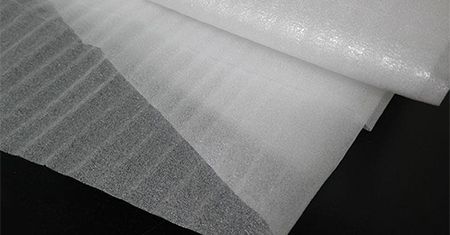

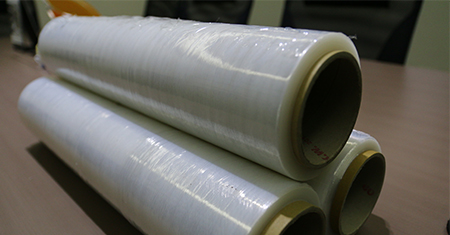

PET、PP、OPP、BOPP、HDPE、LDPE、LLDPE、ABS、HIPS等。特別適用於塑膠薄膜、發泡材料、纖維、編織袋、清洗並擠乾後的薄膜、碎片和邊角料等

|

|

|

| 發泡材 | 薄膜 | HDPE 袋 |

|

|

|

| 不織布 | 塑膠纖維 | 拉鍊 |

- 節能:使用德國減速機馬達,有效地節省電力達20%。

- 節省空間:三機一體結合了粉碎、押出和造粒。模頭切粒無水槽裝置,擺設空間較小。

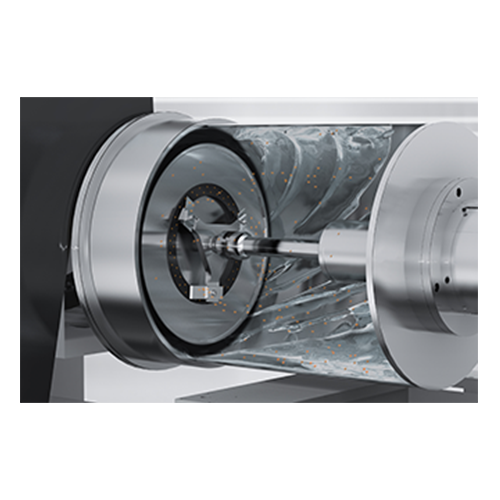

- 高效率:採用免停機雙柱油壓換網,簡單易操作,提升運轉效率和產能。

KRIEGER-150 / 三機一體塑膠回收造粒機 / BOPP薄膜 / 韓國

GENIUS在2019年初,在韓國完成了第5台機器的安裝。

在短短的時間裡,GENIUS的名聲已經傳開整個韓國塑膠產業, 因為我們高品質的機器以及最迅速的服務,讓韓國客戶持續相信我們。

這次我們在韓國裝的是KRIRGER-150,客戶要回收的材質為BOPP、CPP、OPP。

我們知道普遍BOPP、CPP、OPP切粒方式為拉條。然而,模頭切粒方式會比以往的拉條切粒來的穩定且產量較高,但由於模頭切粒不適用每一個材質,所以我們GENIUS團隊致力於將BOPP材質也能夠使用模頭切粒方式。

GENIUS團隊感謝韓國客戶以及代理的信任,陪伴著我們一起成長。未來的GENIUS會持續在韓國發表更多機器。

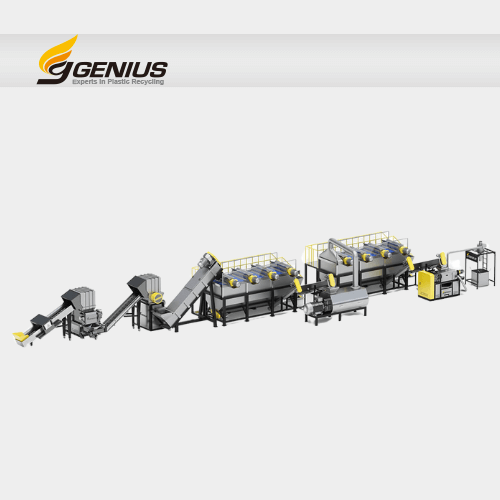

KRIEGER-Z-125i / 三機一體塑膠回收造粒機 / PE發泡 / 韓國

KRIEGER-Z-125i

經過了90天的組裝生產、7天的海運運輸和4天的現場安裝,KRIEGER-Z-125i 塑膠回收造粒機終於在韓國大邱安裝完畢。

新型態的Z type連結式子母回收機

以往市面上看到的傳統型子母機,原料經由主機送到子機的過程,若是轉速沒有設定好,經常會有許多原料卡在子機的料斗上,甚至造成原料的溢流;而且因為原料直接接觸空氣,在這個階段,總是產生大量廢氣。

全新的Z type連結式子母回收機,採用直接連結的方式,原料不再卡在子機的料斗,同時完美解決了過去子母機總是會產生大量廢氣的問題。

另一方便,這種的排列方式也能有效節省空間及人力,只需兩到三名員工就可以運作整套機器。

KRIEGER-Z-125i安裝後,目前已在韓國進行造粒生產中,投入PE foam進行造粒,每小時產能可達到400Kg。

KRIEGER-100 / 三機一體塑膠回收造粒機 / PE薄膜 / 越南

這位客戶是東南亞最大的塑膠吹袋廠,具有五大廠區,共占地超過三百公頃,且生產線上有400台吹袋機同時運作中,主要生產LDPE塑膠袋。

KRIEGER在越南裝機後,在24小時運轉下,每天的產能約13噸,等於每小時產能高達500KG以上

越南的客戶說:KRIEGER能大量將廠內的餘料再次造粒,而且粒子的品質很好,可以直接再拿去吹袋使用,節省了許多成本。自動化的設計,我只需要派兩個員工來顧這台機器就好了,非常實惠,CP值很高。

由於KRIEGER的表現相當亮眼,因此客戶又訂了第二台相同的機型,第二台KRIEGER 100於2017年5月底在越南裝機完畢。