增加入料量

強押側邊入料裝置可確保入料的穩定性,通過穩定的入料量,使押出機的螺桿保持滿載,從而確保最高的輸出。產能提高50%↑。

更加節省人工

入料裝置搭配電流監控系統,並自動控制入料量,以避免過載或入料不足。僅需1~2名工人就可以操作整條生產線。

更靈活的設計

長毅機械提供靈活的選擇,從客製化的回收、分類、入料,脫氣、過濾、造粒到儲存和包裝系統。根據客戶需求提出智能可靠的設備。

| 型號 | RECO-85 | RECO-100 | RECO-125 | RECO-135 | RECO-150 | RECO-175 | |

| 主機螺桿 | Φ85 mm | Φ100 mm | Φ125 mm | Φ135 mm | Φ150 mm | Φ175 mm | |

| 主機馬達 | 756KW | 94KW | 131KW | 150KW | 200KW | 250KW | |

| 產能 | 200~300 ↑ kg/hr | 300~400 ↑ kg/hr | 450~600 ↑ kg/hr | 600~850 ↑ kg/hr | 700~850 ↑ kg/hr | 900~1100 ↑ kg/hr | |

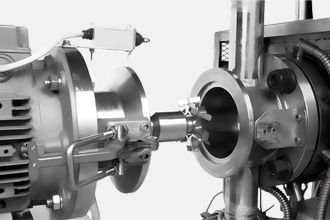

模頭切粒

模頭切粒可省去人工拉條的人力成本。

切粒刀為萬向軸設計,自動調整軸心。切粒時無粉塵。

模頭切粒切出的粒子形狀大小一致,利於再次投入生產線生產和應用。

水中造粒

特別針對高黏性物料所設計的切粒方式。

切粒和冷卻同時進行。

拉條切粒

主要適用於高黏度物料。

拉條切出後經由冷卻水槽降溫後,再由切粒機切粒。

- 螺桿及料筒皆為進口之材料,且經過特殊處理,其耐磨性佳,使用壽命亦較長。

- 單押出機適合較乾淨之物料和水洗後的薄膜、編織袋等蓬鬆回收料。

- 齒輪箱為精密研磨過之齒輪,運轉時噪音較低、平穩順暢。

PET,PP、PS、PE、ABS、HIPS等。適用於塊狀塑膠材料,如瓶片或粉碎過的工業廢料等。

|

|

|

| 化學桶 | HDPE 牛奶瓶 | 射出流道廢料 |

|

|

|

| PET 飲料瓶 | PP 電池盒 | 廢電器零件 |

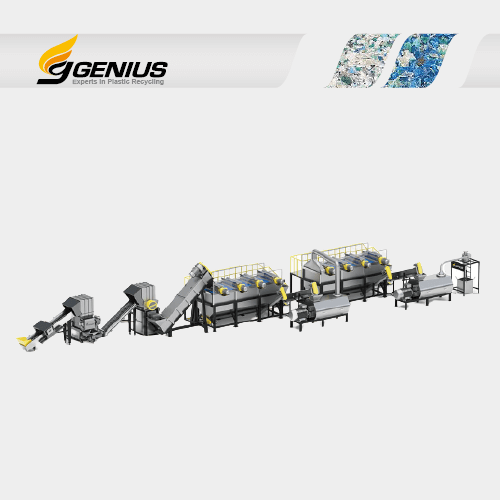

RECO-Y-150i / 強押側入料塑膠回收造粒機 / HDPE 瓶片 / 台灣

是時候淘汰你的舊設備了!

2017年11月底,台灣的第五台RECO系列回收造粒機在台中開始生產。 這位客人主要做HDPE瓶的回收。過去使用的是175mm的螺桿,產能每小時僅有500KG。新的RECO-Z-150i安裝後,螺桿只有150mm,產量高達每小時1100KG。與舊機台相比,相同的馬力、更小的螺桿、更少的耗電,能生產雙倍以上的產量!

這是怎麼辦到的呢?

RECO系列-強押側入料裝置:其穩定且連續的餵料方式,確保螺桿的最大效率。 Z式連結:除了減少原料與空氣接觸產生之廢棄,同時也解決了當原料從主機送至子機時可能會產生架橋的風險。 三段透氣(Degassing)設計:水洗完的HDPE瓶片通常含有一些水分,特殊設計的三段透氣裝置,生產的粒子沒有任何空洞。

https://www.youtube.com/watch?v=rpC9iNN3tm4

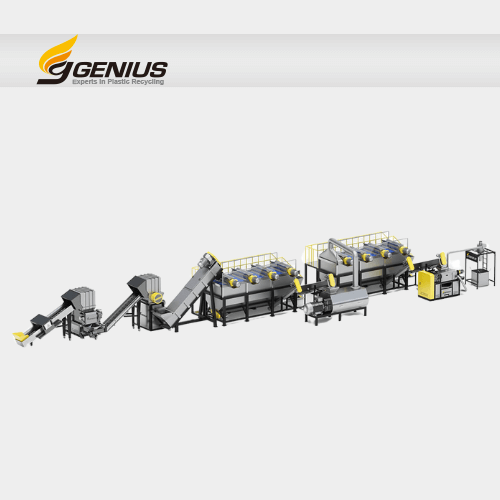

RECO-Z-125i / 強押側邊入料塑膠回收造粒機 / 水洗PE薄膜 / 台灣

現今的社會,人力資源費用越來越高。全球環保意識也不斷提高。 長毅機械 在開發新型塑膠回收機時,總是站在客戶的角度思考,不斷推陳出新。特別推出針對人力需求及環保檢測做改良的 - RECO-Z 系列兩段式塑膠回收造粒機。

現今的社會,人力資源費用越來越高。全球環保意識也不斷提高。 長毅機械 在開發新型塑膠回收機時,總是站在客戶的角度思考,不斷推陳出新。特別推出針對人力需求及環保檢測做改良的 - RECO-Z 系列兩段式塑膠回收造粒機。

RECO-Z 的四大優勢

優勢一: 強押式側邊入料系統

僅需使用較小的馬力,即可達到最高產能! 舉例來說,左圖的入料系統只使用7.5Kw的馬達,然而產能可以高達450 公斤/小時。

優勢二: 強押式子母機設計

獨家設計的強押式子母機設計。不同以往市面上看到的傳統型子母機,採用直接連結的方式,原料不再卡在子機的料斗,同時完美解決了過去子母機總是會產生大量廢氣的問題,杜絕汙染源!

優勢三: Z 型排列設計

有效節省空間及人力! 只需一到兩名員工就可以運作整套機器!

優勢四: 高精密混煉螺桿設計

成品的塑膠粒子具有相當高的拉伸力,針對不同的原料設計的專屬螺桿,可以有效減少熔融時的損耗。

「這台機器所生產的粒子品質相當好,大幅提升了賣價,同時還幫我節省了許多成本。」東芳塑膠的CEO-鍾先生說:「因此,我決定二廠的所有生產線都要換成這種機器。」

東芳塑膠是台灣最大規模的PE薄膜回收業者,每個月生產的塑膠回收粒子高達2,500噸。在東芳塑膠工廠內已經安裝了兩套長毅的塑膠回收造粒機,並已訂了兩套新的機器,預計2017年四月完成安裝。