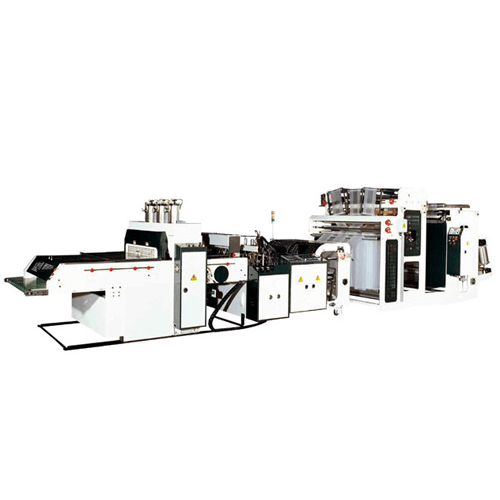

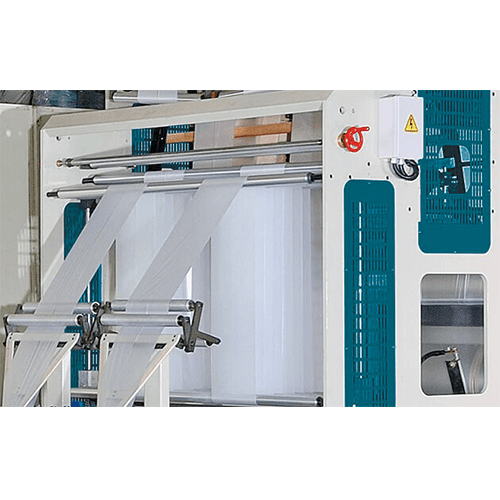

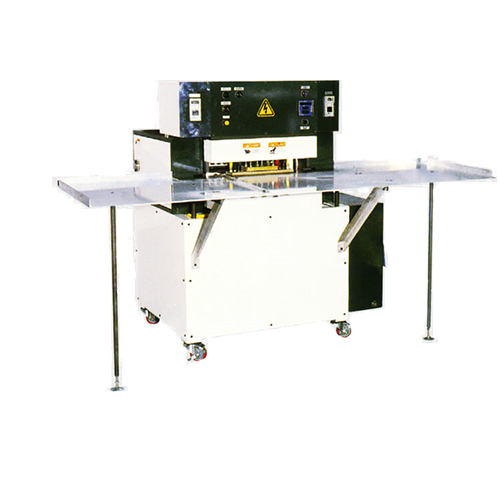

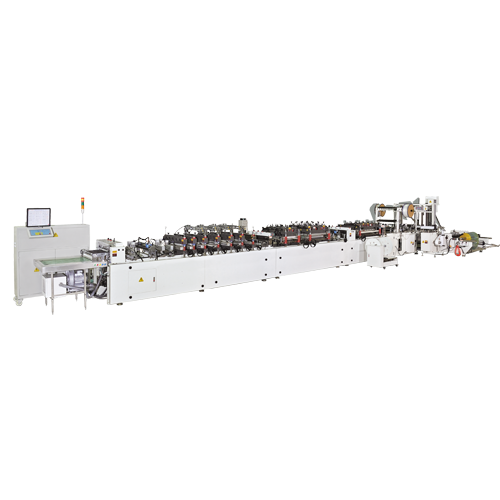

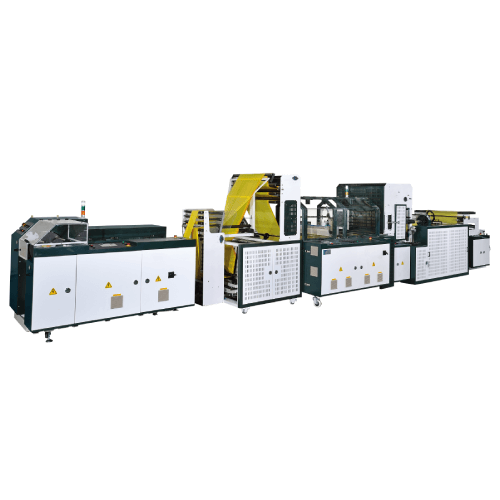

- 熱切割系統+後角板 - 使用超大膜捲和熱切割成多條線,押出膠片1次和打印1次,節省人工成本。

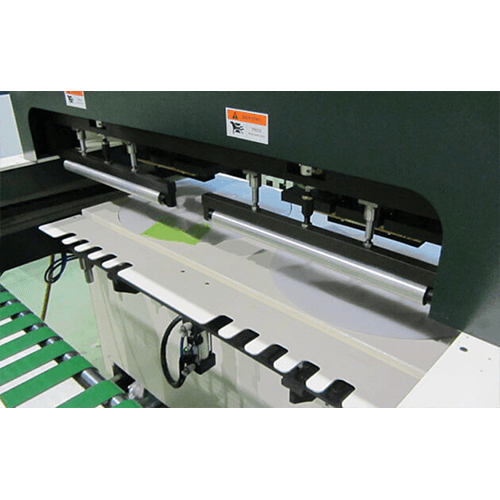

- 高速熱切系統 - 用於印花背心包。機內含有光電管和伺服寄存器,能精確打印位置。而高速熱切系統可用於200/250 / 300rpm系統。

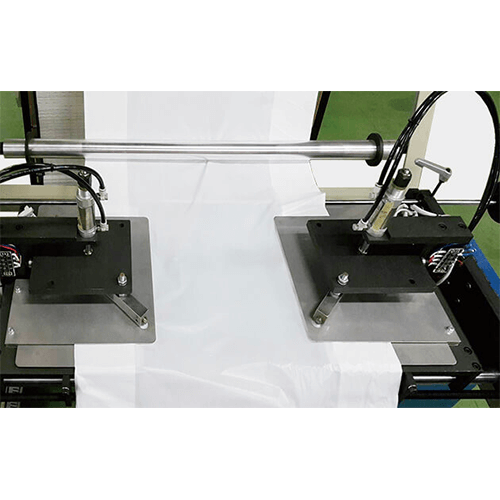

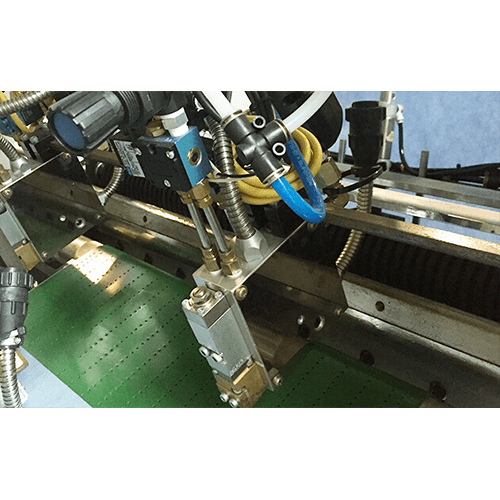

- 全自動固定器和氣動沖頭 - 當計數到達時,在線固定器和氣動沖孔切除並丟棄不需要區域,達成不間斷生產。

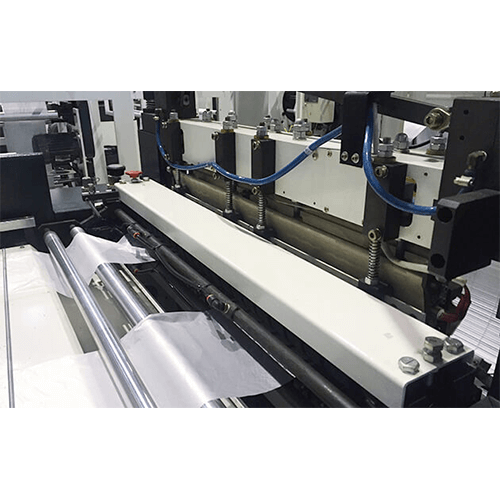

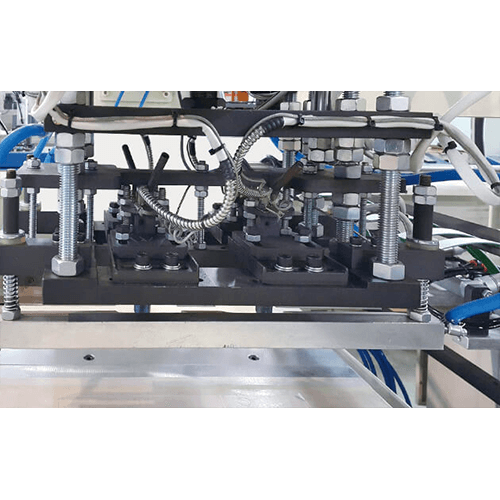

- Tensionless high speed hot-cut system : Upper sealing blade & bottom heating wire makes strong and high speed sealing. Tensionless sealing avoids sealing line pull& elongation for highspeed production. Seperated upper and bottom temperature control for easy micro-adjustment.

- Gripper + pneumatic punch : When counts reached, inline gripper collect and pneumatic punch cut out waste area and removed by conveyor.

- Rocking pin block : Blocking pin base rock back and forth to avoid sealing line sticking to previous bags.

- Synchronized feeding and cutting speed : Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

- German "Sick" photocell registration : Reliable and accurate print registration and positioning

- Auxiliary air-blown outfeed : Air blown assists material flow of outfeeding

- LCD touch panel : Easily operable human-computer interface to access parameter changes and production monitoring

- Socket type IC circuit control : Automated control system can be easily replaced by socket plugin.

- Malfunction alarm / stop : Alarm & auto-stops for abnormal temperature / No material feed / Photocell tracking miss (3 times)

| 模型 | PL32PFA-V300 + SLG2 | PL32PFA-V300 + SLG2 |

| 切割長度(英寸) | 10“-26” | 10“-26” |

| 切割寬度(英寸) | 6“ - 14”×2 | 6“ - 14”×2 |

| SPEED(BAGS / MIN) | 150-600 | 150-560 |

| 薄膜厚度(m / m) | 0.01-0.25 | 0.01-0.25 |

| 容差(M / M) | ±1 | ±1 |

| 功率(千瓦) | 6 | 7.7 |

| NW(KGS) | 1800 | 2100 |

| GW(公斤) | 2300 | 2600 |

|

機器尺寸 長×寬×高(cm) |

700×190×200 | 700×190×200 |

|

包裝尺寸 長×寬×高(cm) |

230×110×210 240×190×180 140×230×230 320×190×210 |

230×130×210 240×210×180 140×250×230 320×210×210  |