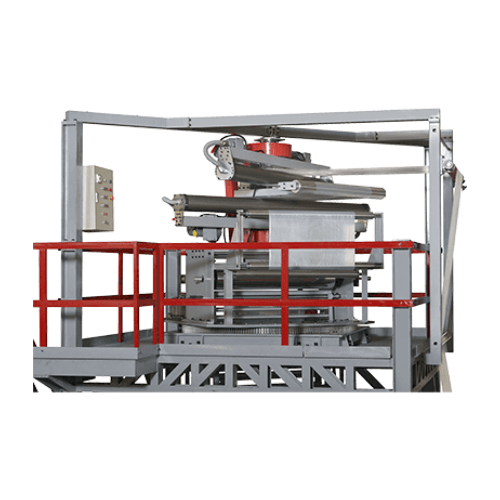

水平擺動牽引適用於不同的塑膠吹膜機,如單層、多層及共擠。它的主要功能是均勻地分散任何不均勻的變化,使薄膜厚度平均。此外,此工作型式可確保薄膜的平整度及高品質。它通常用於製造經濟效益高且薄膜寬度較寬的薄膜。水平式與垂直式均設有限位開關,可讓擺動式牽引機反轉近 360 度,以達到薄膜的平均厚度。根據不同的材料,迴轉度是可調整的。

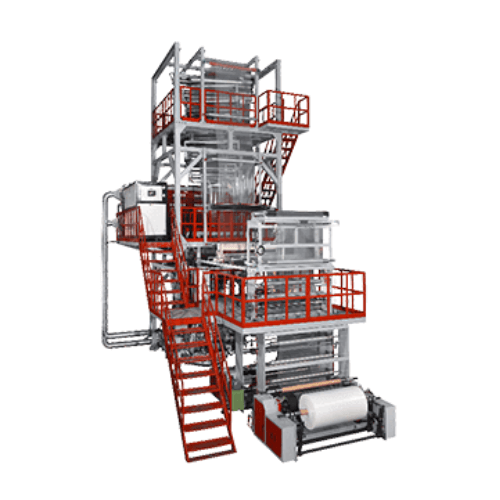

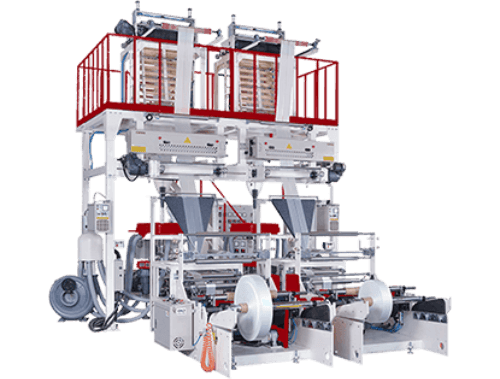

當薄膜第一次從 Die Head 出來時,它是熔融型的。透過管子將空氣吹入熔融的薄膜,薄膜便會變成氣泡管。在 Stabilizer / Blown Film Bubble Cage 的支撐下,氣泡管就能以穩定的形狀拉伸。針對材質的不同,折疊框架提供木製與鋁製兩種材質供客戶選擇。到達頂端收料裝置的位置後,再經過由壓輪與鋼輪所組成的壓輪。這兩個滾輪的互動作用會將氣泡管中的空氣全部擠出,使氣泡管非常平整,沒有任何皺紋。此外,變頻器與馬達驅動提供穩定的線速 (收料速度),可連續拉出泡泡管。對於需要雙面夾邊膜的客戶,也可搭配夾邊裝置。

- 帶來經濟效益

- 提高薄膜的平整度

- 增加薄膜平均厚度適用於各類塑膠吹膜機

- 馬達採用變頻控制

- 折疊框架可分為木質及鋁質兩種